Find the right pump for your demand

Our products

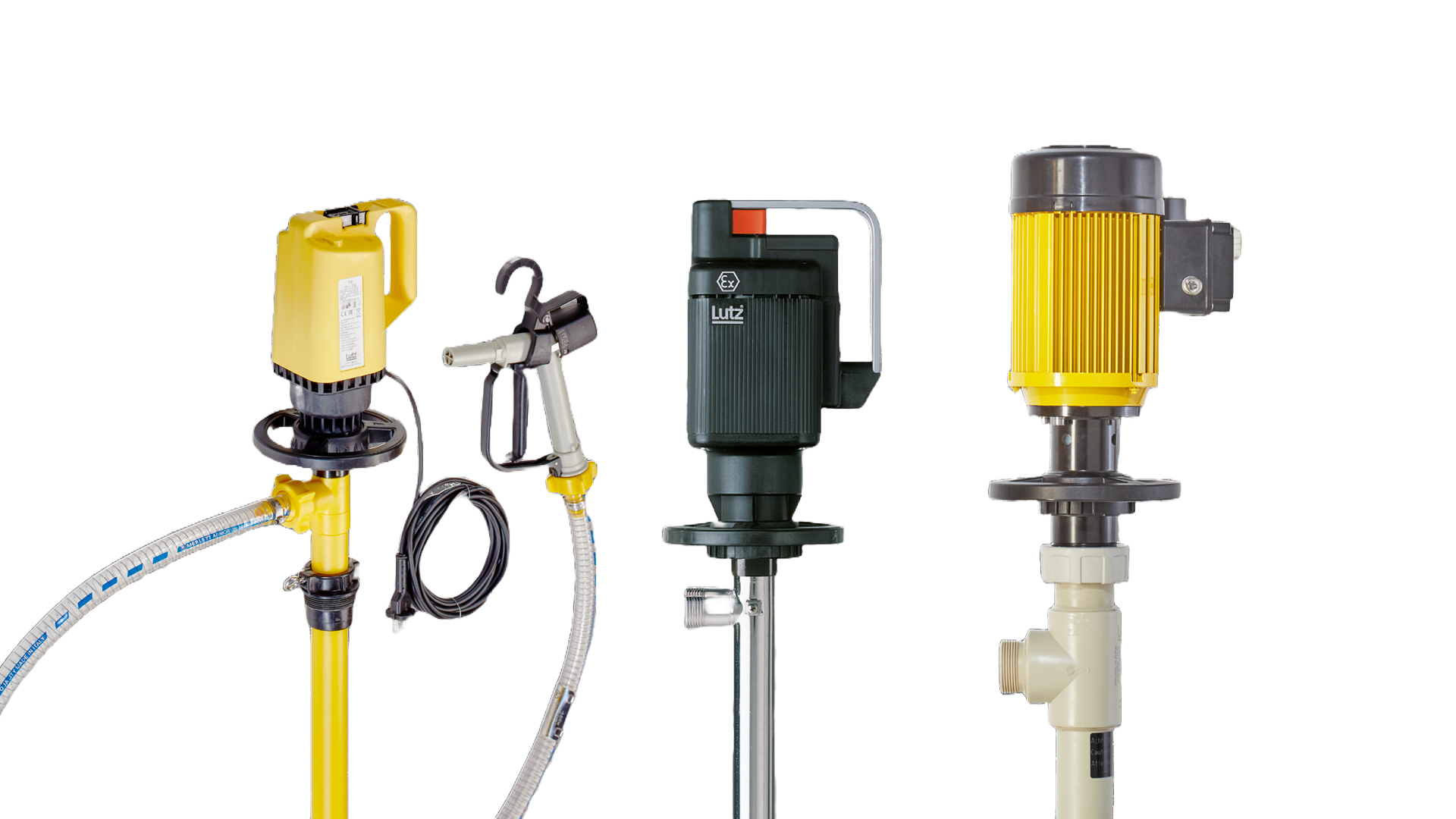

Our complete range of pumps

electric

Internally ventilated

Universal motor MI 4 / MI 4-E

MI4

Description

The MI 4 motor is suitable for non-flammable, aqueous to slightly viscous liquids. Depending on the application, various motors with the appropriate voltage are available, which you can combine with the pumping station at any time. This gives you flexibility at all times and conserves important resources.

Optionally with speed controller to adjust the delivery rate

Internally ventilated motor

Features & advantages

Quick and easy disassembly

Light and easy to handle

Powerful motor

electric

Complete set

Pump set - Mineral oils

for oils and lubricants

Description:

The pump set is suitable for low-viscosity, aggressive and non-flammable media. Perfectly suited for the extraction or decanting of mineral oils.

Examples of media: Diesel, heating oil, hydraulic oil, machine oil and engine oil etc.

Pumping unit equipped with Lutz Original handwheel

Suitable for filling or decanting alternative fuels

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

Optimised drum emptying

Universally resistant ETFE shaft bearing

Maintenance without special tools

Sealing modules of the sealless (DL) pump can be replaced

Motor MA II 5

Description

The MA II 5 motor is suitable for aqueous to slightly viscous, aggressive and outgassing liquids. Depending on the application, various motors with the appropriate voltage are available, which you can combine with the pump unit at any time. This gives you flexibility at all times and saves important resources.

Optionally with undervoltage release

Externally ventilated motor

Also available as an acid protection version

Features & benefits

Double insulation with protective conductor connection

Optimised cooling air routing

Double-walled housing protects the internal parts from corrosion

Robust and solid construction

New

Battery

Pump tube set

Pump unit set LubeDrive

Filling pump for lubricating greases and gear oils

The mobile complete solution for grease & gear oil - quiet, efficient, completely mains-independent

Mobile complete set for workshop & construction site - without electricity, without compressed air

Whether on the construction site, in the workshop or in the field: The LubeDrive pumping unit set delivers lubricants to where they are needed - quickly, quietly and powerfully. Ideal for centralised lubrication systems and gearbox oil filling.

Developed for maintenance technicians who need flexibility

In agricultural and construction machinery technology, every minute counts. With the LubeDrive set, vehicles and systems can be filled directly on site - without any manual force or compressed air. Workshops in particular benefit from a simple, ready-to-use solution.

No more inefficient pumping

The set combines robust technology with maximum user-friendliness. Simply connect the cordless screwdriver - and work more efficiently than ever before. Quieter and faster than pneumatic systems, significantly less effort than with hand pumps.

✅ Your benefits with the LubeDrive pump set:

Operation with a standard cordless screwdriver - no special tools required

Without compressed air & electricity: Maximum mobility in any application environment

Up to 2 kg/min pumping capacity: Saves valuable working time

For greases up to NLGI-2 & gear oils

Compatible with 10-60 kg containers

Noticeably quieter than pneumatic systems

Robust design for rough everyday working conditionsFor construction and agricultural vehicles in mobile useDeveloped for workshops and maintenance teams

electric

Drum pump

Drum pumps - Mineral oils

for oils and cooling lubricants

Description:

The drum pump is suitable for low-viscosity, aggressive and non-flammable media. Perfectly suited for the removal or decanting of mineral oils.

Examples of media: Diesel, heating oil, hydraulic oil, machine oil and engine oil etc.

Pumping unit equipped with Lutz Original handwheel

Suitable for filling or decanting alternative fuels

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

Optimised drum emptying

Universally resistant ETFE shaft bearing

Maintenance without special tools

Sealing modules of the sealless (DL) pump can be replaced

Explosion protection

electric

Drum pump

Drum pumps - Solvent

for highly flammable hydrocarbons

Description:

The drum pump is suitable for low-viscosity, flammable and highly flammable hydrocarbons. Perfectly suited for the removal or decanting of solvents.

Optionally available with Ex plug

Pumping unit equipped with Lutz original handwheel

Suitable for filling or transferring alternative fuels, oils and flammable liquids

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

Highly resistant high-grade carbon shaft bearing

Maintenance without special tools

Sealing modules of the sealless (DL) pump can be replaced

Approved in accordance with ATEX Directive 2014/34/EU, category 1/2

electric

Drum pump

HC Wave

Drum pumps - Acids

for acidic liquids

Description:

The drum pump is suitable for corrosive, aqueous to slightly viscous media. Perfectly suited for the removal or decanting of acids.

Examples of media: Hydrochloric acid, battery acid, iron-III-chloride, phosphoric acid, chromic acid and citric acid etc.

Pumping unit equipped with Lutz original handwheel

Suitable for filling or decanting oils such as rapeseed oil and vegetable oil

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

Optimised drum emptying

Universally resistant PTFE shaft bearing

Maintenance without special tools

Sealing modules of the sealless (DL) pump can be replaced

Motor MA II 7

Description

The MA II 7 motor is suitable for aqueous to slightly viscous, aggressive and outgassing liquids. Depending on the application, various motors with the appropriate voltage are available, which you can combine with the pump unit at any time. This gives you flexibility at all times and saves important resources.

Optionally with undervoltage release

Externally ventilated motor

Features & benefits

Double insulation with protective conductor connection

Optimised cooling air routing

Double-walled housing protects the internal parts from corrosion

Robust and solid construction

Stainless steel shaft

Impeller

Pump tube aluminium

for mineral oils

Description:

The Lutz pumping station (aluminium) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application, various motors are available that you can combine with the pumping station at any time. This gives you flexibility at all times and saves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pumping unit equipped with Lutz Original handwheel

Suitable for filling or transferring alternative fuels

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped medium by lubricants

Optimised drum emptying

Universally resistant ETFE shaft bearing

Maintenance without special tools

Sealing modules of the mechanical seal (GLRD) or of the sealless (DL) pump interchangeable

Basic

Motor MA II 3

Basic - 460 W - 230 V

Description

The MA II 3 motor is suitable for aqueous to slightly viscous, aggressive and outgassing liquids. Depending on the application, various motors with the appropriate voltage are available, which you can combine with the pump unit at any time. This gives you flexibility at all times and saves important resources.

Optionally with undervoltage release

Externally ventilated motor

Features & benefits

Double insulation with protective conductor connection

Optimised cooling air routing

Double-walled housing protects the internal parts from corrosion

Robust and solid construction

electric

Complete set

Pump set - B2 Vario Niro

for liquid lubricants and cleaning agents

Description:

The B2 Vario pump set is suitable for low-viscosity, aqueous to slightly viscous media. The set is suitable for dispensing small containers such as canisters, hobbocks and drums. The pump is flexible at all times and thus conserves important resources.

Infinitely variable speed controller for transferring and filling small quantities

Features & advantages

Sealless design (DL) conditionally dry-running safe

Infinitely variable

Powerful motor with improved service life

Easy to service and dismantle

Explosion protection

electric

Complete set

Pump set for Complete drainage - Solvent

for highly flammable hydrocarbons

Description:

The pump set is suitable for low-viscosity, flammable and highly flammable hydrocarbons and is perfect for dispensing or decanting solvents.

Examples of media: Ethanol, petrol, butanol, isopropanol, paraffin, methanol and petroleum, etc.

Pumping unit equipped with Lutz original handwheel

Suitable for emptying drums of alternative fuels, oils and flammable liquids

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

optimised drum emptying with a residual quantity of approx. 0.1 litre

No leaks if the pumping station is tilted or moved

Maximum product utilisation with reduced drum cleaning and disposal costs

Approved in accordance with ATEX Directive 2014/34/EU, category 1/2

Explosion protection

Compressed air

Comfort grip

Compressed air motor MD2xL

with comfort grip

Description

The MD2xL motor is suitable for viscous, highly flammable, combustible liquids up to 100,000 mPas. With the oil-free, 1000 watt high-performance air motor, you can achieve the same delivery rate as comparable products with 20% less connection pressure and 4% less air consumption.

Explosion-proof motor in accordance with ATEX directives

Can be used oil-free

Features & benefits

High performance and high efficiency thanks to optimised flow control

Very good handling due to low weight

Long service life

Very good starting behaviour

HC Wave

Impeller

Pump tube PVDF

for concentrated acids and alkalis

Description:

The Lutz pumping station (PVDF) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application, various motors are available that you can combine with the pumping station at any time. This gives you flexibility at all times and saves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pumping unit equipped with Lutz original handwheel

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

Optimised drum emptying

Universally resistant PTFE shaft bearing

Maintenance without special tools

Seal modules of the mechanical seal-sealed (GLRD) or seal-less (DL) pump are interchangeable

Explosion protection

Motor ME II 8

Description

The ME II 8 motor is suitable for low-viscosity, highly flammable, combustible and outgassing liquids. Depending on the application, various motors with the appropriate voltage are available, which you can combine with the pump unit at any time. This gives you flexibility at all times and saves important resources.

Optionally with undervoltage release

Externally ventilated motor

Explosion-proof motor in accordance with ATEX directives and IEC Ex

Features & benefits

Double insulation with protective conductor connection

Optimised cooling air routing

Double-walled housing protects against corrosion of the internal parts

Protection against vapours

Long service life

Explosion protection

Impeller

Pump tube Niro

for flammable liquids

Description:

The Lutz pumping station (stainless steel) is suitable for low-viscosity, flammable and explosive liquids. Depending on the application, various motors are available which can be combined with the pumping station at any time. This gives you flexibility at all times and saves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pumping unit equipped with Lutz original handwheel

Suitable for filling or transferring alternative fuels, oils and flammable liquids

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped medium by lubricants

Approved in accordance with ATEX Directive 2014/34/EU, category 1/2

Highly resistant high-grade carbon shaft bearing

Maintenance without special tools

Seal modules of the mechanical seal-sealed (GLRD) or seal-less (DL) pump are interchangeable

HC Wave

Impeller

Pump tube PP

for low-viscosity acids

Description:

The Lutz pumping station (PP) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application, various motors are available that you can combine with the pumping station at any time. This gives you flexibility at all times and saves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pumping unit equipped with Lutz Original handwheel

Suitable for filling or decanting oils such as rapeseed oil and vegetable oil

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped medium by lubricants

Optimised drum emptying

Universally resistant PTFE shaft bearing

Maintenance without special tools

Sealing modules of the mechanical seal (GLRD) or of the sealless (DL) pump interchangeable

horizontal

Pump tube B200 PVDF

for concentrated acids and alkalis

Description:

The horizontal pumping unit is suitable for emptying highly aggressive, aqueous to slightly viscous media from IBC containers or tanks and is the perfect alternative to vertical drum pumps. Perfectly suited for the removal of concentrated acids and alkalis.

Optionally with leakage detection (safety box)

Horizontal connection at the bottom of the container

IBC connection: S60 x 6

Features & benefits

Optionally with electric or compressed air drive

Low loss of medium when disconnecting

Simple installation

Easy to dismantle

Small space requirement

Automatic emergency stop function of the motor when leakage is detected

electric

Drum pump

Drum pumps - concentrated acids and alkalis

for highly chemical liquids and salts

Description:

The drum pump is suitable for corrosive, aqueous to slightly viscous media and is perfect for dispensing or decanting concentrated acids and alkalis.

Examples of media: Chloric acid, chromic acid, sulphuric acid, nitric acid, hydrofluoric acid and sodium hypochlorite etc.

Pumping unit equipped with Lutz original handwheel

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

Optimised drum emptying

Universally resistant PTFE shaft bearing

Maintenance without special tools

Sealing modules of the sealless (DL) pump can be replaced

Explosion protection

electric

Complete set

Pump set for Complete drainage - Explosive media

For aggressive and highly flammable liquids

Description:

The pump set is suitable for low-viscosity, flammable and highly flammable liquids and hydrocarbons. Perfectly suited for the removal or decanting of explosive media and solvents.

Optionally available with Ex plug

Pumping unit equipped with Lutz original handwheel

Suitable for emptying drums of alternative fuels, oils and flammable liquids

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

optimised drum emptying with a residual quantity of approx. 0.1 litre

No leaks if the pumping station is tilted or moved

Maximum product utilisation with reduced drum cleaning and disposal costs

Approved in accordance with ATEX Directive 2014/34/EU, category 1/2

Stainless steel shaft

Impeller

Pump tube PP

for low-viscosity alkaline solutions

Description:

The Lutz pumping station (PP) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application, various motors are available that you can combine with the pumping station at any time. This gives you flexibility at all times and saves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pumping unit equipped with Lutz Original handwheel

Suitable for filling or decanting oils such as rapeseed oil and vegetable oil

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped medium by lubricants

Optimised drum emptying

Universally resistant PTFE shaft bearing

Maintenance without special tools

Sealing modules of the mechanical seal (GLRD) or of the sealless (DL) pump interchangeable

Battery

Complete set

Battery pump set - B2 Battery Niro

for liquid lubricants and cleaning agents

Description:

The B2 Battery pump set is suitable for low-viscosity, aqueous to slightly viscous media. The set is suitable for dispensing small containers such as canisters or hobbocks. The pump is flexible at all times and thus conserves important resources.

Replaceable, powerful rechargeable battery with Li-Ion

Battery life 35 min at maximum speed

1 battery charge empties approx. 12 x 200 litre containers

Features & benefits

BLDC motor with high efficiency of up to 70%

Infinitely variable

Long battery life

Automatic switch-off in case of overload

Sophisticated quick-release fastener

electric

Drum pump

Stainless steel shaft

Drum pumps - caustic solutions

for low-viscosity chemicals

Description:

The drum pump is suitable for corrosive, aqueous to slightly viscous media and is perfect for removing or transferring alkaline solutions.

Examples of media: Sodium hydroxide, potassium hydroxide, ammonia water, formic acid and acetic acid etc.

Pumping unit equipped with Lutz Original handwheel

Suitable for filling or decanting oils such as rapeseed oil and vegetable oil

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

Optimised drum emptying

Universally resistant PTFE shaft bearing

Maintenance without special tools

Sealing modules of the sealless (DL) pump can be replaced

Explosion protection

ROTOR

Pump tube Niro

for flammable liquids

Description:

The Lutz pumping station (stainless steel) is suitable for low-viscosity, flammable and explosive liquids. Depending on the application, various motors are available which can be combined with the pumping station at any time. This gives you flexibility at all times and saves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pumping unit equipped with Lutz original handwheel

Suitable for filling or transferring alternative fuels, oils and flammable liquids

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped medium by lubricants

Approved in accordance with ATEX Directive 2014/34/EU, category 1/2

Highly resistant high-grade carbon shaft bearing

Maintenance without special tools

Seal modules of the mechanical seal-sealed (GLRD) or seal-less (DL) pump are interchangeable

Your contact person

Lutz Pumpen | Contact

Do you have questions about drum pumps, container emptying, double diaphragm pumps, flow measurement or centrifugal pumps?

Our team of experts will be happy to assist you. Please send us an enquiry or call us directly.

+49 9342 879 - 260

anfrage@lutz-pumpen.de