Pump technologies for phosphating systems

Centrifugal pumps – efficient transport and safe water treatment

Our horizontal centrifugal pumps with a magnetic coupling provide phosphating systems with the ideal solution for the safe transport of aggressive liquids such as acids and alkalis from storage tanks or IBC containers into process basins. Our centrifugal pumps can also be deployed in the water treatment of phosphating systems. For example, they ensure that lime milk can be dosed into neutralisation systems in a constant fashion. They also pump demineralised water and ensure circulation in the degreasing bath.

- Simple to integrate

- A robust construction

- Long service life

- Low maintenance during operation

- Ideal for wastewater treatment

- No leaks

- No mechanical seal

Drum pumps – reliable pumping and precise dosing

Our chemical-resistant drum pumps enable the safe and controlled pumping of 98% sulphuric acid into the pickling bath. The B2 Vario drum pump also performs the exact dosing of flocculants in water treatment, thereby ensuring effective wastewater treatment and reliable process safety.

- Chemically resistant

- Exact dosing

- Safe pumping

- Easy handling

- Ergonomic

Dosing pumps – for the precise and safe dosing of additives

Enabling the controlled and reliable dosing of additives into process basins, our dosing pumps are ideal for degreasing, activation and passivation.

- High chemical resistance

- Highly precise

- Maximum reliability

Container pumps – for the safe transfer of phosphorus from IBC containers

Our B200 container pump performs the simple and safe transfer of phosphorus directly from IBC containers into process basins.

- Easy to operate

- Reliable performance

- Protection against dangers

- Compact design

- Ergonomic

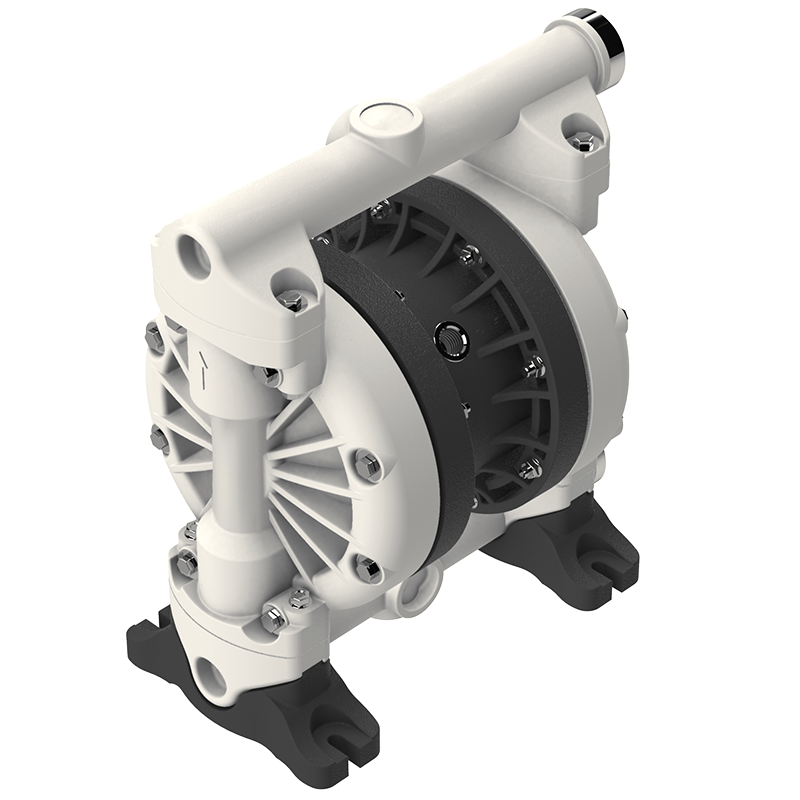

Double diaphragm pumps – flexible and safe chemical return

Our double diaphragm pumps represent the ideal solution for the flexible and mobile return of spilled chemicals. They are also suitable for ensuring the reliable transport of slime into filter presses.

- Chemically resistant

- High performance

- Versatile applications

- Easy maintenance

- Long service life

anfrage@lutz-pumpen.de