Select a category

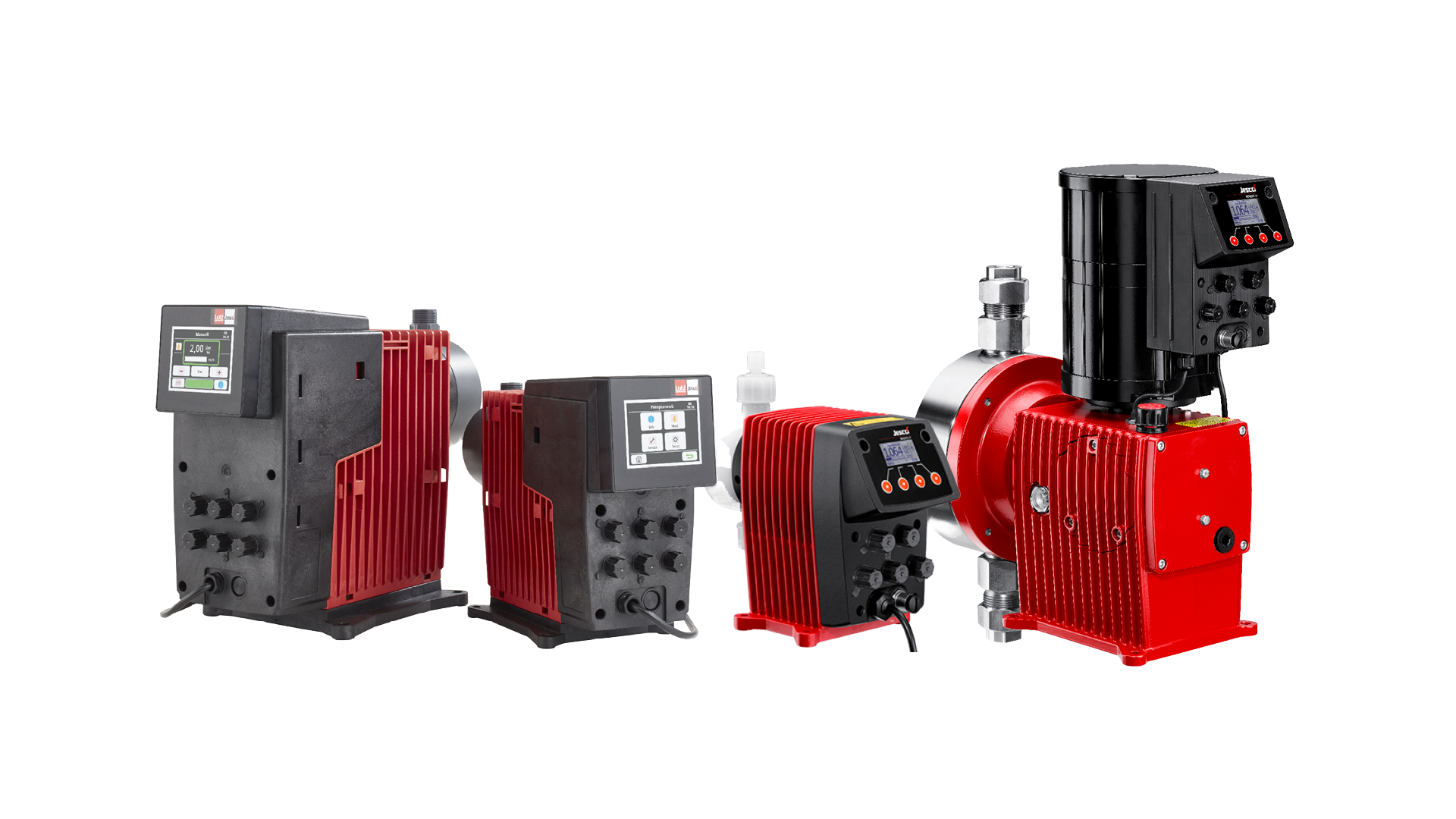

Our complete range of dosing pumps

MEMDOS SMART LPX

MEMDOS SMART LPX - reliable dosing of chemicals

With the new stepper motor technology of the MEMDOS SMART LPX, even the smallest quantities can be dispensed with high precision.The new generation offers a variety of attractive solutions for demanding and complex dosing tasks. The LPX series is available in eight performance ranges and is suitable for network operation (Modbus RTU).In addition, the new generation of smart pumps has a full-colour 3.5-inch touchscreen display for simple and safe operation.And for even more flexibility, the Smart pumps can be ordered ex works with a left or right-rotating display

1 rejection rate 1000:1 for MEMDOS SMART LPXGraphic display with multilingual menu

Display of the flow rate in 7 different units

Pump base for standard or wall mounting

Password protection and adjustable ranges

Alarm status shown in colour on the display

Calibration mode

Slow mode: 25 %, 50 %, 75 %

Diaphragm change programme

Venting function

Storage of messages

Software backup of four memory locations

Removable display: (optional)

Display position rotated (optional)

Available on request: Multiple Pumps can be operated via one display

Manual control, 0 - 100 %

Pulse control, constant or dynamic

Analogue control 0/4 - 20 mA, scalable

Batch dosing: manual start, external start, interval or timer function

Network operation, Modbus RTU

Enable input (external start / stop)

Level input with pre- and main alarm

Pulse input, overshoot and undershoot

Analogue input 0/4 - 20 mA

Diaphragm rupture detection (optional)

Pulse output: stroke feedback, alarm or pulse forwarding

Analogue output 0/4 - 20 mA, scalable

Alarm relay output (1 and 2), adjustable

MEMDOS SMART LAX

MEMDOS SMART LAX - reliable dosing of chemicals

With the new stepper motor technology of the MEMDOS SMART LAX, even the smallest quantities can be dispensed with high precision.The new generation offers a variety of attractive solutions for demanding and complex dosing tasks. The LAX series is available in eight performance ranges.In addition, the new generation of smart pumps has a full-colour 3.5-inch touchscreen display for easy and safe operation.And for even more flexibility, the Smart pumps can be ordered ex works with a left or right-rotating display.

Graphic display with multilingual menu

Flow rate display in 7 different units

Pump base for standard or wall mounting

Password protection and adjustable ranges

Alarm status shown in colour on the display

Calibration mode

Removable display: (optional)

Display position rotated (optional)

Available on request: Multiple Pumps can be operated via one display

Manual control, 0 - 100 %

Analogue control 0/4 - 20 mA, scalable

Enable input (external start / stop)

Level input with pre- and main alarm

Analogue input 0/4 - 20 mA

Analogue output 0/4 - 20 mA, scalable

MEMDOS SMART LDX

MEMDOS SMART LDX - reliable dosing of chemicals

With the new stepper motor technology of the MEMDOS SMART LDX, even the smallest quantities can be dispensed with high precision.

The new generation offers a variety of attractive solutions for demanding and complex dosing tasks. The LDX series is available in eight performance ranges.In addition, the new generation of smart pumps has a full-colour 3.5-inch touchscreen display for easy and safe operation.And for even more flexibility, the Smart pumps can be ordered ex works with a left- or right-hand display.

Graphic display with multilingual menu

Display of the flow rate in 7 different units

Paper base for standard or wall mounting

Password protection and adjustable ranges

Alarm status shown in colour on the display

Calibration mode

Removable display: (optional)

Display position rotated (optional)

Available on request: Multiple Pumps can be operated via one display

Manual control, 0 - 100 %

Pulse control, constant or dynamic

Enable input (external start / stop)

Level input with pre- and main alarm

Pulse input, overspeed and underspeed

Pulse output: stroke feedback

Peristaltic pump: PERIDOS FXM 2

PERIDOS FXM 2 - The low-maintenance Peristaltic pump: for abrasive and outgassing mediaHigh performance. Low maintenance. Industry 4.0-ready.The PERIDOS FXM 2 from Lutz-Jesco is the high-performance peristaltic pump for abrasive, viscous or corrosive media - designed for maximum process reliability, ultra-fine dosing and uninterrupted 24/7 operation.For demanding dosing processes in harsh industrial environments

Whether in water and wastewater treatment, the chemical industry or mining: the FXM 2 impresses with its precise delivery, intuitive control and maintenance-optimised design. Ideal for anyone who expects robust technology without compromises.Precise dosing with maximum control

The FXM 2 doses up to 176 l/h at a delivery pressure of 8.6 bar - with an exceptional turndown ratio of 5000:1. This means that even fine adjustment down to 0.035 l/h is possible - ideal for sensitive processes with high reproducibility.Real-time monitoring & leakage protectionThanks to the optional Flow Verification Sensor (FVS) and non-contact leak detection (TLD), the FXM 2 recognises deviations immediately - and actively protects your processes from downtime, loss of quality or environmental damage.Maintenance in minutes - without special toolsThe hose is the only wearing part. It can be replaced in a few simple steps and without tools - completely without dismantling. This saves you time, reduces your operating costs and increases the availability of your system.Intelligent networking - ready for Industry 4.0Digital interfaces such as Ethernet/IP, Modbus TCP, 4-20 mA or 0-10 VDC enable seamless integration into existing SCADA and control systems. Up to 17 operating states can be recorded, analysed and actively controlled.

✅ Advantages of the Peristaltic pump: FXM 2:

Self-priming & dry-running safe: Maximum reliability in 24/7 operation

High delivery capacity: up to 176 l/h at 8.6 bar - ideal for abrasive and corrosive media: ...Industry-4.0-capable: Ethernet/IP, Modbus TCP, 0-10 VDC, 4-20 mALow maintenance & efficient: tool-free hose change in just a few minutes

Robust construction: Powder-coated aluminium, chemical-resistant hoses

SCADA-compatible : Up to 17 operating parameters can be analysed

Digitally networkable: SCADA/DCS integration via Modbus TCP, Ethernet/IP, 0-10 VDC, 4-20 mA

Predictive maintenance: Optional pump monitor & leakage sensor for predictive maintenanceCertified & safe: UL 778, CSA, WQA (NSF/ANSI/CAN 61 & 372)

Peristaltic pump: PERIDOS FXM 3

PERIDOS FXM 3 - Maximum Power for demanding pumping processes

The PERIDOS FXM 3 from Lutz-Jesco is the most powerful Peristaltic pump in the FXM series - built for high-volume pumping processes with aggressive, abrasive or viscous media. Reliable. Low maintenance. Fully networkable.

Ideal for high-volume dosing processes under difficult conditions

Whether in the pulp, chemical or construction industry - the FXM 3 offers a combination of throughput, precision and process monitoring that is unrivalled in harsh industrial environments.

Powerful, precise and smart

With a flow rate of up to 840 l/h at 4.5 bar, the FXM 3 is the ideal solution for high-volume applications with high process reliability requirements. Thanks to the 5000:1 turndown ratio, the flow rate can be precisely controlled to less than 0.2 l/h - with a repeatability of ±1 %.Maintenance? Takes only minutesThe hose is the only media-carrying element and can be replaced in just a few minutes without special tools - and without dismantling. This reduces maintenance costs and increases system availability.Seamless monitoring. Digital control.With the optional Flow Verification Sensor (FVS), capacitive leakage detection (TLD) and up to 17 analysable operating states, the FXM 3 enables seamless monitoring of your processes - for safe and predictive production.Fully integrated - ready for the futureThanks to industrial communication protocols (Ethernet/IP, Modbus TCP, 0-10 V, 4-20 mA), the FXM 3 can be seamlessly integrated into digital control systems. It is operated via an intuitive touchpad with menu-driven software - efficient, error-free and ready for immediate use.

✅ Advantages of the PERIDOS FXM 3 at a glance:

Highest delivery capacity: Up to 840 l/h at 4.5 bar - ideal for large-volume processes

Safe continuous operation: Self-priming, safe to run dry, insensitive to gasIndustry-4.0 interfaces: Ethernet/IP, Modbus TCP, 0-10 VDC, 4-20 mA

Real-time process monitoring: Flow Verification Sensor & TLD leakage control

Turndown ratio 5000:1: Ultra-fine control down to 0.17 l/h possibleHighest precision & low energy consumption: ±1 % repeatability due to precision-manufactured rollersCertified & safe: UL 778, CSA, NSF/ANSI/CAN 61 & 372

Robust construction: High-quality materials for maximum durability

Pressure Loading and Relief Valves

Description:Keeps the operating pressure of the pump constant Pressure loading and relief ralves are fittings for dosing plants. They are used, according to the user's requirements, to increase dosing accuracy or to protect the plant against excess pressure. Where the supply pressure is higher than the dosing pressure, dosing is not possible without a pressure loading valve.Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-Back_Pressure_Valve.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-Back_Pressure_and_Pressure_Relief_Valves.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Back_pressure_and_pressure_relief_valves-EN-BA.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-Back_Pressure_Valve-Spanish.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-Back_Pressure_and_Pressure_Relief_Valves-Spanish.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Valvulas_de_retencion_y_sobrecarga-ES-BA.pdf

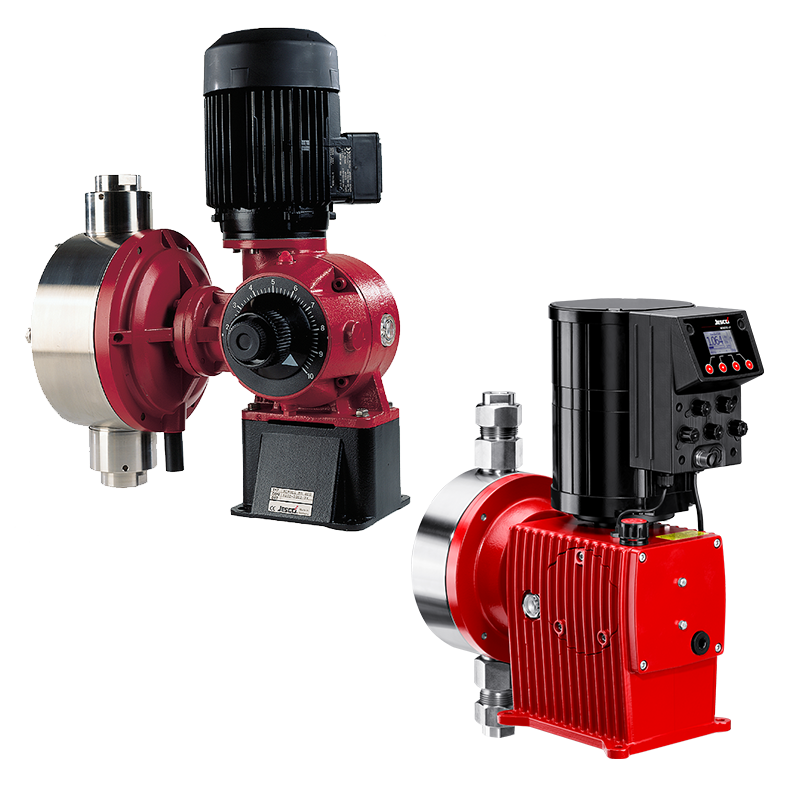

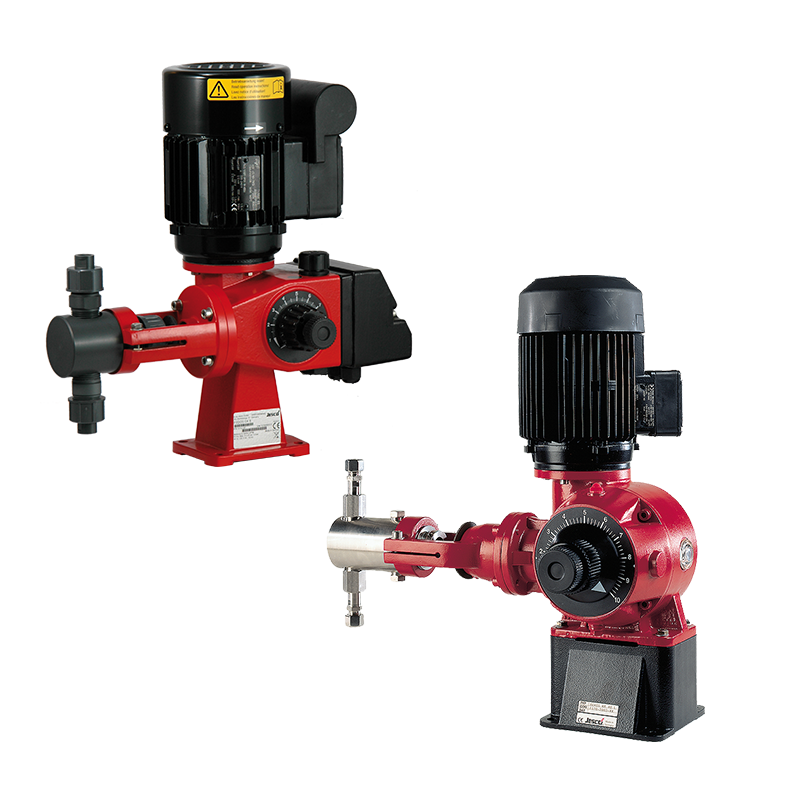

MEMDOS LB

Description:Riding on the crest of the waves The MEMDOS LB is used when the integration of the pump into controls or control circuits is required. Thanks to the sturdy tappet drive with manual or automatic capacity adjustment, the conveyed media such as acids, lyes, coagulants and flocculants are dosed reliably and precisely. To adapt the dosing capacity, either the stroke length can be adjusted mechanically or the speed of the three-phase motor can be regulated by means of a separate frequency converter. On request, the MEMDOS LB pumps can also be supplied with a double-diaphragm system.Features & advantages: Capacity range 1.06 – 324 gph, up to 232 psig Power supply 115 V, 230 V or 400 V Material finishes PVC, PP, PVDF and stainless steel Infinitely variable stroke length from 0 – 100 % A variety of three-phase and alternating current motors ATEX versions are available for Zones 1 and 2 Also suitable for frequency converter operation Double-diaphragm system (optional) Automatic stroke length adjustment (optional) MEMDOS LB 44-HP1010-HP2020-HP356080150 Delivery capacity at max. pressure50 Hzgph 1.062.223.706.355.829.5216.6723.8141.27 60 Hz 1.32.74.47.67.011.4202950 Max. back pressurepsig 17423217423217423214572 Nominal stroke frequency 50 HzRPM 26721207212072120 60 Hz 31.286.414486.414486.4144 Suction lift for non-gassing mediaft H2O 292623 Max. supply / inlet pressurepsig 7.3 Diameter of diaphragmin 2.0472.5193.543 Valve size DN4DN6DN10 Voltage supply 230 / 400 V (optional 115 V) Protection class IP55 Insulation class F Material PP, PVC, PVDF, 1.4571 Weight* PPlb 11.511.115 PVC 11.111.114.1 PVDF 11.911.915 Stainless steel (1.4571) 17.617.626.5 Max. ambient temperature°F 316SS & PVDF: 113° / PVC: 104° Max. temperature of the medium°F 316SS & PVDF: 176° / PP: 140° / PVC: 95° MEMDOS LB 1101602102603104005107601010 Delivery capacity at max. pressure50 Hzgph 30.238.155.669.877.8103.2133.3196.8269.8 60 Hz 3646678493124160236324 Max. back pressurepsig 145116875844 Nominal stroke frequency 50 HzRPM 9612096120961205376107 60 Hz 115.2144115.2144115.214463.691.2128.4 Suction lift for non-gassing mediaft H2O 2319143 Max. supply / inlet pressurepsig 7.3 Diameter of diaphragmin 3.5434.7245.9057.283 Valve size DN10DN15DN25 Voltage supply 230 / 400 V (optional 115 V) Protection class IP55 Insulation class F Material PP, PVC, PVDF, 1.4571 Weight*PPlb 25.327.531.745.8 PVC 25.327.531.745.8 PVDF 26.028.633.549.6 Stainless steel (1.4571) 36.846.557.793.2 Max. ambient temperature°F 316SS & PVDF: 113° / PVC: 104° Max. temperature of the medium°F 316SS & PVDF: 176° / PP: 140° / PVC: 95° Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-MEMDOS_LB-EN-BA.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-MEMDOS_LB.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-MEMDOS_LB-Spanish.pdf

Priming Aids

Description:For a perfect dosing result All types of dosing pumps with low flow rates per stroke often haven priming problems which grow as the suction lift and the liquid density increase. Low flow rates may be due to the size of the pump or to a reduced stroke adjustment. The priming difficulties during start-up result from dry valves as well as from the high air volume within the suction line still being unfilled and the dosing head. In dosing systems with frequent periods of disuse, the priming aid is of great use because it makes priming much easier for the pump.Features & advantages: Syphon-type collector ASH without pumping device AHP with pumping device Types 65, 95, 250, 3000 and 5000 Priming aid ASH 659525030005000 Version Priming aid PVC, seals FPMPriming aid PVC transparent, seals FPMPriming aid, PVC transparent, seals FPM / EPDM Installation Connected suction side on the dosing pumpWall mounting with clamps or container fitting with stand possible Connection sizes G5/8, G3/4Hose 4/6, 6/8Hose 6/12 Glued socket Ø32 Priming volume 65 ml95 ml250 ml 3000 ml5000 ml Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-Priming_Aid-Spanish.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-Priming_Aid.pdf

Pulsation Dampener PDS

Description:For a perfect dosing result Pressure variations in hydraulic pipe layouts and tube fittings give rise to irregular operation and can, in cases of great amplitude variations, cause damage to the pipework and even fracture fittings. These pulsation dampeners represent a simple countermeasure to bring any increasing pressures to harmless proportions.Features & advantages: Stroke volume 15 – 1200 ml/stroke Hose as a separating diaphragm Compressed air as a dampening gas pocket Integration in the pressure line is possible PDS 8025075025007500 Stroke volume*ml/stroke 15401204001200 perm. operating pressurebar 104 Pre-tension pressurebar max. 62,5 Temperature°C max. 50 Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/produktinfos/LJ-PDS-EN-PI.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Pulsation_Dampener_PDS-EN-BW.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Pulsation_Dampener_PDS-EN-MB.pdf

MAGDOS LD

Description:Simple to use and space-saving MAGDOS LD plays an important role in the reliable and accurate dosing of liquids in process sequences and is available in seven power ranges. Double-ball valves ensure accurate dosing. To adapt the dosing performance, the stroke frequency can be adjusted manually or via an external control contact. The dosing pump is compact and, thanks to the small mounting area, can be integrated into every dosing system in a very space-saving way. It can be mounted in three different positions without further attachments: standing, left- or right-oriented on a wall.Features & advantages: Capacity range from 0.09 to 4.00 gph, max. back pressure 232 psig Power supply 230 V ±10 %, 50/60 Hz, IP65 or 115 V ± 10 %, 50/60 Hz Dosing head ventilation Suitable for wall and floor mounting Material finishes PVC, PP, PVDF Stroke frequency can be precisely adjusted via the keyboard Graphic display Pulse input (increase and reduction) Level input with early warning and main alarm Release input for external start/stop Calculation wizard for pulse operation available online CSA and UL certified MAGDOS LD 0512461015 Delivery capacity at max. pressuregph 0.090.200.500.891.642.403.43 ml/stroke 0.050.20.310.570.830.86 Max. pressurepsig 2321168743 Delivery capacity at medium pressuregph 0.140.290.611.01.802.644.00 ml/stroke 0.080.070.240.350.630.921 Average pressurepsig 116584314 Nominal stroke frequencyRPM 120250160180250 Suction lift for non-gassing mediaft H2O 1696 Max. inlet / supply pressurepsig 11 Diameter of diaphragmin 0.9441.2991.535 Valve size DN3DN4 Voltage supply 230 V, ± 10 %, 50/60 Hz or 115 V, ± 10 %, 50/60 Hz Power consumptionW 813192522 Protection class IP65 (with covering caps on the connections) Insulation class F Material PVC, PP, PVDF Weightlb ~ 7 Ambient temperature range°F PVDF 113° (104° with PVC parts) Max. temperature of the medium°F PVDF 176°F (with PVC parts 95°; with PP parts 140°) Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-MAGDOS_LA_LD-EN-BA.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-MAGDOS_LD.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-MAGDOS_LD-Spanish.pdf

5710 Series

Description:Hydraulically actuated non-lost motion Diaphragm Pump Models 5710 metering pumps are an hydraulically actuated non-lost motion (amplitude modulated) diaphragm design. The unique method of actuation, by means of a rotating plunger, provides smoother, quieter operation. The design characteristics minimize back lash and shock loads to the process system. Models 5710 are among the longest lasting pumps in the industry. These pumps will provide reliability in the heaviest workload environments, such as mining, nuclear plants, power plants and refineries/petroleum applications. These pumps meet API 675 standards.Features & advantages: A micrometer stroke length adjustment allows effortless capacity control of 0-100% Operating pressure up to 4000 psig Power supply - single phase or 3-phase TE or XP motor Built-in pressure relief valves Compact design offers high capacity per square foot of space Double ball check valves High mechanical efficiency reduces power requirements 5710 Series Max. pressurepsig 4000300025001750 Simplex capacitygph 7.7122033 Duplex capacitygph 15234167 Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/O_M-5710_Series.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-5710_Series.pdf

PENTABLOC

Description:Safety valve with 5 functions The accuracy of diaphragm dosing pumps is affected by the back pressure. In pressureless (open) systems, or systems with excessive pressure the dosing pumps must be protected. Undesired flow rates resulting from siphoning must be avoided. The multifunction valve PENTABLOC has been designed to solve the aforementioned problems.Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/produktinfos/LJ-PENTABLOC-EN-PI.pdf

FLOWCON LP 1

Description:Flow control The FLOWCON LP 1 flow sensor was specially developed for monitoring oscillating volume flows. Thanks to ist particularly compact design it can be installed directly on a pump's discharge valve. It uses a reed switch to forward flow fluctuations in the line as an electric pulse. Software embedded in the MAGDOS LP is used to analyse the FLOWCON signal. As an alternative, the system can analyse the FLOWCON using an SPS.Features & advantages: Efficient monitoring of pulsating volume flows Compact design, highly robust product Easy handling Capacity between 0.36 and 13 l/h Electric analysis using MAGDOS LP or performed externally using SPS Housing material PMMA / PVC Sealing material FPM or EPDM ConnectionsInput Cap nut G5/8 Output Threaded pin G5/8 Dosing range MAGDOS LP 05 – 15 Max. viscosity 400 mPas (dependent on spring used) If the dosing pump is used MAGDOS LP 15: 40 mPas Max. back pressure 16 bar Max. stroke frequency 250 min-1 Electrical connection M12x1 plug connector (A-coded) Permitted media temperature 5 – 35 °C Permitted ambient temperature 0 – 40 °C Switching capacity reed switch 48 V AC/DC, 0.5 A, max. 12 VA Weight 0.26 kg Description Order no. PVC baseClamp connection 4/6 - G5/8 34560 Clamp connection 6/9 - G5/8 40934 Clamp connection 6/12 - G5/8 34561 PVC wall bracketG5/8 34563 Description Order no. Spare spring for viscosities of up to 150 mPas 23788 Spare spring for viscosities of up to 400 mPas 22016 Spare reed switch 79615 Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-FLOWCON_LP_1-EN-BA.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/produktinfos/LJ-FLOWCON_LP_1-EN-PI.pdf

MAGDOS DE

Description:Reliable dosing of chemicals Solenoid-diaphragm dosing pumps play an important role in the reliable and accurate dosing of liquids in the process cycles. They are appropriate for low-pressure applications and small dosing quantities. Dosing pumps are used in many branches of industry that work with liquid chemicals - not excluding toxic and aggressive media.Features & advantages: Capacity range from 4.7 to 27.7 gph, up to 150 psig Suitable for toxic and aggressive media Stroke length adjustable 0 – 100 % Stroke frequency adjustable 0 – 100 % DE 20 – 100: 0 – 70 /min. Switchable to external control (e.g. water meter) DE 20 – 100: up to 70 pulse/min. Pulse and level control input electrically isolated Connection for level control (pre- and main alarm) Warning alarm relais and/or digital display (optional) Double-ball valves for highest accuracy All types are available for German standard DVGW-DIN 19635 115 V model CSA proofed available MAGDOS DE 2040100 Max. pressurepsig 1506030 Delivery capacity at max. pressuregph 4.712.727.7 Nominal stroke frequency SPM 70 Suction lift for non-gassing mediaft. H2O 654 Diameter of diaphragmin 2.53.54.7 Power supplyV AC 115/230 Power consumptionW 66/70 Protection class IP65 Input pulse durationms > 30 Pulse inputV DC 5 Weight (plastic)lb ~ 29 Weight (stainless steel)lb ~ 33 Max. ambient temperature°F 104° Max. temperature of the medium°F Stainless Steel/PP/PVDF 120° (95° with PVC parts) Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-MAGDOS_DE_DX-EN-BA.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-MAGDOS_DE_DX.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-MAGDOS_DE_DX-Spanish.pdf

Contact Head Water Meters

Description:For a perfect dosing result Even when there are large flow fluctuations ideal proportional dosing is achieved by contact head water meters emitting pulses in proportion to the flow rate. The water meters are multijet wet-operating types with summarizing dosing works.Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/produktinfos/LJ-Contact_water_meter-EN-PI.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Contact_Head_Water_Meters-EN-MB.pdf

Electrical Degassing Device AUTOVENT

Description:For a perfect dosing result AUTOVENT is a manually adjustable degassing system for low flow metering pumps. The AUTOVENT allows the pump to be easily vented, thereby preventing system downtime caused by excessive amounts of gas having entered the pump head.Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-Autovent.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-Autovent-Spanish.pdf

Peristaltic pump: PERIDOS FXM 1

PERIDOS FXM 1 - Peristaltic pump: for precise micro-dosing under extreme conditions

Compact. Low maintenance. Reliable.

The PERIDOS FXM 1 from Lutz-Jesco is the ideal solution for precise dosing tasks with aggressive, viscous or abrasive media - even under the toughest conditions and in continuous operation.

Your solution for controlled dosing of aggressive media

Whether precipitants in water treatment, additives in food production or chemicals in laboratories and Industry: The FXM 1 offers you reliable Power in the smallest of spaces - hygienic, self-priming and dry-running safe.

Developed for demanding applications

With a delivery volume of 2.8 l/h at 1.5 bar, the FXM 1 is perfect for fine dosing tasks. It works with low pulsation, is reversible and does not require any non-return valves - this ensures reliable processes and high dosing accuracy.

Compact and fully integrated

The FXM 1 combines the drive, controller, electronics and pump head in one housing - for minimum space requirements and maximum efficiency. It can be easily integrated into existing systems and is ideal for modular applications or series assembly.

Minimal maintenance effort

Thanks to its clear design, the only part in contact with the medium is the hose - this can be changed in just a few minutes without tools. This significantly reduces downtimes and maintenance costs.

Reliability in continuous operation

The FXM 1 is self-priming, safe to run dry and insensitive to gas bubbles. It works reliably - even with an interrupted supply or empty pipes - without damaging the system.

✅ Advantages of the FXM 1 Peristaltic pump:

Compact & integrable: Cased-drive design for easy installation

Delivery volume 2.8 l/h: Ideal for precise dosing of small quantities

Low maintenance: Hose change in minutes, without tools

Self-priming & dry-running safe: Operation without non-return valves possible

Gas-resistant: Also pumps outgassing media such as sodium hypochlorite

Low-pulsation flow: For stable processes in sensitive applications

Robust materials: Parts in contact with the media are made of chemical-resistant plastic

Universally applicable: In chemistry, water treatment, Foodstuffs, agricultural technology

Electric Agitators

Description:For a perfect dosing result In dosing technology, agitators are useful accessories in order to mix the media to be metered homogeneously. Especially in the case of powdery additives or liquids which are difficult to dilute, the high-speed propeller agitators are essential. Suspensions must be circulated permanently or at least periodically so that the distribution of the substance remains homogeneous.Features & advantages: AC or 3-phase current motors Agitators are fitted with a three-blade PVDF or stainless steel propeller Pitch of the propeller blades is left-handed (media to be mixed is delivered towards the bottom) Agitator shafts are mounted directly on the motor shaft Agitators are available in stainless steel, stainless steel with PVDF coating or stainless steel with PP coating Standard lengths: 500, 700, 800, 900 and 1000 mm Type JR...WSJR...DSJR...WSJR...DSJR...DSJR...DS Nominal powerkW 0.090.120.180.250.370.75 Nominal speedmin-1 142013701450142014001400 Recirculation capacitym3/h ~50~70~70~70~100~200 Tank size up 300 lup 500 lfrom 500 lfrom 500 lup 1000 lup 3000 l Propeller Ømm 100100100100125150 Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Electric_Agitator-EN-MB.pdf

MEMDOS LP

Description:Riding on the crest of the waves The MEMDOS LP is used when the integration of the pump into controls or control circuits is required. For integration into demanding automation networks, a version with an Ethernet-based MODBUS interface is available. Thanks to the sturdy tappet drive with manual or automatic capacity adjustment, the conveyed media such as acids, lyes, coagulants and flocculants are dosed reliably and precisely. On request, the MEMDOS LP pumps can also be supplied with a double-diaphragm system.Features & advantages: Capacity range from 1.1 to 270 gph, max. back pressure 232 psig Power supply 230 V, ± 5 %, 50/60 Hz Material finishes PVC, PP, PVDF and stainless steel Stroke frequency can be precisely adjusted via the keyboard Precise pump adjustment via the keyboard Graphic display with multi-language menu Analogue input 0/4 – 20 mA Pulse input (increase and reduction) Level input with early warning and main alarm Release input for external start/stop Supply amount displayed in various units Maximum delivery rate can be limited Stroke feedback output Batch dosing with interval and timer functions Dosing control input Alarm relay output Analogue output 0/4 – 20 mA Diaphragm rupture detection and reporting (optional) Double-diaphragm system (optional) Ethernet interface (optional) MEMDOS LP 44-HP1010-HP2020-HP356080150 Delivery capacity at max. back pressuregph 1.12.23.76.05.89.616.72441 Max. back pressurepsig 17423217423217423214572 Max. stroke frequencySPM 26721207212072120 Suction lift for non-gassing mediaft H2O 292623 Max. supply pressurepsig 7.3 Diameter of diaphragmin 2.0472.5193.543 Valve size DN4DN6DN10 Voltage supply 230 V Protection class IP55 Insulation class F Material PVC, PP, PVDF, Stainless Steel Weight PVClb 252628 PP 252628 PVDF 252730 Stainless steel 303241 Ambient temperature range°F 41-113° (104° with PVC parts) Max. temperature of the medium°F 176° (with PVC parts 95°; with PP parts 140°) MEMDOS LP 1101602102603104005107601010 Delivery capacity at max. back pressuregph 3038567078103133197270 Max. back pressurepsig 14511810388665844 Max. stroke frequencySPM 9612096120961205376107 Suction lift for non-gassing mediaft H2O 2319143 Max. supply pressurepsig 7.3 Diameter of diaphragmin 3.5434.7245.9057.283 Valve size DN10DN15DN25 Voltage supply 230 V Protection class IP 55 Insulation class F Material PVC, PP, PVDF, Stainless Steel WeightPVClb 43.445.65067.2 PP 43.445.65067.2 PVDF 44.146.751.571 Stainless steel 5564.575.8115 Ambient temperature range°F 41-113° (104° with PVC parts) Max. temperature of the medium°F 176° (with PVC parts 95°; with PP parts 140°) Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-MEMDOS_LP-EN-BA.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-MEMDOS_LP.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-MEMDOS_LP-Spanish.pdf

Moisture Cartridge

Description:For a perfect dosing result The requirement for gas-tightness or insulation from the atmosphere does not, however, mean that the contents of the tank should be hermetically sealed off from the atmosphere. Moisture cartridges avoid pressure load on chemical tanks and also prevent both, moisture from entering the tank and also the emission of any chemical into the atmosphere during filling.Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Moisture_Cartridge-EN-MB.pdf

More Dosing Pumps Accessories

Description:For a perfect dosing result Additional dosing accessories - uuseable in many applications: dosing heads, stroke sensors, needle shutoff valves,dirt traps, separating chambers, flow controllers.Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/produktinfos/LJ-Accessories-EN-UE.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Dirt_Trap-EN-MB.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Dosing_Heads_Autom_Venting-EN-MB.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Flow_Monitor-EN-MB.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-Leakage_Probe.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Metering_Head_Venting-EN-MB.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Needle-Shutoff-Valves-EN-MB.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/produktinfos/LJ-Pump_bracket-EN-PI.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Separating_Chamber_Diaphragm_Pump-EN-MB.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-Stroke_sensor-EN-MB.pdf

1710 Series

Description:Hydraulically actuated Tubular Diaphragm Design The Model 1710 metering pump is a hydraulically actuated tubular diaphragm design. The memory of the pre-stressed diaphragm returns to its exact reference position on every suction stroke giving the pump exceptional accuracy, outstanding lift capabilities and minimal NPSH requirements. A rugged cast iron housing contains a high performance worm and wheel drive that operates in an oil reservoir insuring long life.Features & advantages: A micrometer stroke length adjustment allows effortless capacity control of 0-100% Max. operating pressure up to 2000 psig Power supply - single phase or 3-phase TE or XP motor Built-in pressure relief valves Unique hydraulic vent and refill design Single ball check valves 1710 Series Plunger diameter 1/2"3/4"1"1.4" Max. pressurepsig 20001000400200 Capacitygph 4.8102080 Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/O_M-1710_Series.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-1710_Series.pdf

MEMDOS MR / 2300

Description:Powerful motor-driven diaphragm dosing pump Diaphragm dosing pumps of the MEMDOS MR / 2300 series have been developed for a broad range of applications. Thus they are used in the industrial sector, in process engineering and very frequently in water and waste water treatment. They are leakproof. Standard versions are with the head located on the left-hand side. dosing pumps with the head on the right-hand side can be supplied. Duplex dosing pumps are available with the head combinations shown in the following tables. The heads are arranged in diagonals.Features & advantages: Capacity range from 17 to 310 gph (single head) max. back pressure 150 psig PP and stainless steel dosing heads Double-ball valves (up to MR 290) Spring-loaded flat-seat valves (starts with MR 400) Spring-loaded single-ball valves (optional) Separation chamber between dosing head and gearbox, with drainage pipe Stroke adjustment either manually or electrically (ATE) Dublex head pumps (optional) Stroke counter with inductive detector for charge-processes (optional) Frequency converter controlling (optional) MEMDOS MR / 2300 Series 231123212331234123512361237123812391 Max. pressurepsig 1507560 Delivery capacity at max. pressuregph 172843517692139203310 Stroke frequencySMP 5886124861245886124 Diameter of diaphragmin 3.54.75.97.30 Suction lift for non-gassing mediaft H2O 9 6 Max. temperature of the medium°F PP 120°; 316SS 175° Weight (incl. motor) with single, plastic headlb 626684 Weight (incl. motor) with single, stainless steel headlb 7595106 Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/O_M-2300_Series.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-Model_2300.pdf

MAGDOS LP

Description:Simple to use and space-saving MAGDOS LP is available in seven power ranges. Double-ball valves ensure accurate dosing. The dosing power can be adapted by varying the stroke frequency manually, via an external control contact or using a 0/4 – 20 mA signal. The MAGDOS LP is also available with an optional Ethernet interface. This network connection enables you to control the stroke frequency and the number of strokes. In addition, all error messages can be transmitted in the opposite direction.Features & advantages: Capacity range from 0.09 to 4.00 gph, max. back pressure 232 psig Wide - range power supply unit 110 – 240 V, 50/60 Hz, IP65 Dosing head ventilation (plastic version) Suitable for wall and floor mounting Material finishes PVC, PP, PVDF and stainless steel Stroke frequency can be precisely adjusted via the keyboard Graphic display with multi-language menu Analogue input and pulse input (increase and reduction) Level input with early warning and main alarm Release input for external start/stop Supply amount displayed in various units Maximum delivery rate can be limited Energy-saving "Eco-mode" is available Stroke feedback output Alarm relay output Batch dosing with interval and timer functions Dosing control input Diaphragm failure input for leak monitoring Ethernet interface (optional) CSA and UL certified MAGDOS LP 0512461015 Delivery capacity at max. pressuregph 0.090.200.500.891.642.403.43 ml/stroke 0.050.20.310.570.830.86 Max. pressurepsig 2321168743 Delivery capacity at average pressuregph 0.140.290.611.001.802.644.00 ml/stroke 0.080.070.240.350.630.921 Average pressurepsig 116584314 Nominal stroke frequencyRPM 120250160180250 Suction lift for non-gassing mediamWS 532 Max. supply / inlet pressurepsig 11 Diameter of diaphragmin 0.9441.2991.535 Valve size DN3DN4 Voltage supply 110 – 240 V, -10 % / +5 %, 50/60 Hz Power consumptionW 10152127282926 Protection class IP65 (with covering caps on the connections) Insulation class F Material PVC, PP, PVDF, 1.4571 WeightPVC, PP, PVDFlb ~ 7 Stainless Steel ~ 9.5 Ambient temperature range°F Stainless Steel/PVDF 41° - 113° (41° - 104° with PVC parts) Max. temperature of the medium°F Stainless Steel/PVDF 176° (with PVC parts 95°; with PP parts 140°) Downloadshttps://www.lutzjescoamerica.com/fileadmin/data/dokumente/pg1/LJ-MAGDOS_LK_LP-EN-BA.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-MAGDOS_LP.pdfhttps://www.lutzjescoamerica.com/fileadmin/data/data_usa/documents/pg1/Spec_Sheet-MAGDOS_LP-Spanish.pdf

Your contact person

Lutz Pumps, Inc.

Do you have questions about drum pumps, container emptying, double diaphragm pumps, flow measurement or centrifugal pumps?

Our team of experts will be happy to assist you. Please send us an enquiry or call us directly.

001 / 770 / 9 25 12 22 or (800) 8 43 39 01 toll free

infolpi@lutzjescoamerica.com