Progressing cavity pumps Accessories

Filter

PP

Barrel adapter

for the eccentric worm-drive pump B70V

Description:

The drum adapter is required to secure the pump in the drum opening. It prevents the pump from tipping over when the drum is empty.

Features & advantages

Material made of PP / St 37

brass

Bypass valve

for progressive cavity pumps B70

Description:

The bypass valve is recommended when using a shut-off valve.

Shut-off valve for nozzles, ball valves, etc.

Features & advantages

Made of brass / stainless steel

Opening pressure: 2.5 bar (brass version) / 5 bar (stainless steel version)

Connection type: 1 1/2"

Carrying handle

for motor MA II and ME II

Description:

The support bracket makes it easier to lift the pump out of or immerse it in the drums or containers. With an explosion-protected drive motor, the explosion-protection switch is attached to the support bracket

for motor MA II / ME II / B4/GT / three-phase motor / single-phase motor / three-phase motor for reduction gearboxes

Features & advantages

No heavy lifting necessary

Makes it easier to lift out or immerse the motor either with or without pump unit

Carrying handle

with integrated pulse sensor

Description:

The support bracket with integrated pulse sensor is the perfect upgrade for your B70V-D progressive cavity pump. Magnetic pulses from the rotating motor shaft are transmitted contactlessly to the pulse sensor via a pulse generator ring. The recorded pulses are analysed in the Lutz BE10 operating unit and output as the pumped flow rate on the display based on the previously determined calibration factor. By adding the RM10 relay module and corresponding connection cables, the system can also be used as a filling/transfer station with quantity preselection (batch function), as is known from the modular Lutz flow meters. Alternatively, the reed pulses can also be analysed via customer evaluation units and external control units.

The pulse transmitter ring and operating unit must be ordered separately

Can be combined with RM10 relay modules and other modules

Features & advantages

Simple operation and control

Cost-effective retrofitting for existing B70V-D progressive cavity pumps

Maximum mobility thanks to compact unit

Explosion protection

Edelstahl

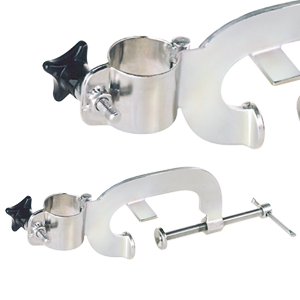

Clamping device

for progressive cavity pump B70V

Description:

The clamping device is for fastening the B70V progressive cavity pump in open and thick-walled drums and containers.

Suitable for a wide range of pumping station diameters

Features & advantages

Made of stainless steel

Explosion protection

Alternating current

CEAG

Ex socket outlet

for ME II motor and for B70V-SR (Ex)

Description:

The CEE socket outlets are suitable for three-phase motors (three-phase current) and electric motors (alternating current) and are used in potentially explosive areas or environments.

Splash-proof

Features & benefits

Certification: EEx de IIC T6

Protection class: IP 65

Rotary (3-pole) or alternating current (5-pole)

Explosion protection

Wechselstrom

CEAG

Ex-plug

for ME II motor and for B70V-SR (Ex)

Description:

The CEE round plugs are suitable for three-phase motors (three-phase current) and electric motors (alternating current) and are used in potentially explosive areas or environments.

Splash-proof

Features & benefits

Certification: EEx de IIC T6

Protection class: IP 65

Rotary (3-pole) or alternating current (5-pole)

Explosion protection

Stainless steel

Foot strainer for progressing cavity pumps

for the progressive cavity pump B70V

Description:

The foot strainer can be used for progressive cavity pumps. By attaching the strainer to the pump foot, coarse impurities can be kept away from important components such as the drive.

For attaching to the pump base

Features & advantages

Prevents contamination in the pumping station by filtering it out

Material: Stainless steel (1.4571)

DN 9 (3/8")

Hose clamps

for hose size DN 9

Description:

The hose clamp is made of stainless steel and is suitable for attaching the various delivery hoses to the hose connection.

Nominal sizes: DN 9 / DN 13 / DN 19 / DN 25 / DN 32 - 38 / DN 50

PP

DN 50 x 2" internal thread

Hose connection

for DMP 2" and B70-V

Description:

The hose connection connects the delivery hoses to the pressure/suction nozzles of the double diaphragm pumps or the dispensing nozzle. When using a double diaphragm pump, either a suitable reducing nipple or a threaded bottle must be used in addition to the hose connection.

Special connections are available on request

Properties & advantages

Materials PP / PVDF / stainless steel

Connections: DN 38 x 1 1/2" female thread / DN 50 x 2" female thread

Stainless steel

DN 25 (1")

Hose connection

for internal thread 1 1/2"

Description:

For connecting the delivery hoses to the B70V-D pumping station.

Nominal sizes: DN 25 / DN 32 / DN 38

Features & advantages

Connection thread: 1 1/2"

Stainless steel material

DN 38 (1 1/2")

Seal FPM

Hose connection

with Tri-Clamp DN 50

Description:

The hose connection with Tri-Clamp is required to connect the delivery hose to the B70 progressive cavity pump, the discharge elbow or the Tri-Clamp fittings (consisting of hose nozzle, locking clamp and seal).

For progressing cavity pumps

Properties & advantages

Material stainless steel (1.4404)

For hoses with nominal diameter DN 38 / DN 50

Explosion protection

DN 19 (3/4")

FPM

Hose integration

with Tri-Clamp DN 32

Description:

For connecting conductive delivery hoses to the pump, nozzle/outlet elbow or Tri-Clamp fittings in potentially explosive atmospheres. The hose connection ensures a good conductive transition between the conductive hose and pump/fitting. The ohmic resistance between the fittings must be less than106 ohms. The hose connection consists of a hose connector, a clamping shell, a locking clip and a seal.

For progressing cavity pumps

Properties & advantages

Stainless steel materials (1.4404)

Only suitable in conjunction with the universal chemical hose

in accordance with the DIN EN 12 115 standard

Explosion protection

Messing

Hose integration

for progressing cavity pumps

Description:

The hose connection ensures a good conductive transition between the hose and the pumping station. The use of conductive hoses is mandatory in potentially explosive atmospheres. The ohmic resistance between the fittings must be less than106 ohms.

For progressive cavity pumps and double diaphragm pumps

Properties & advantages

Made of brass / stainless steel (1.4571)

For hoses with nominal diameter DN 32 / DN 38 / DN 50

DN 19 (3/4")

2 m

Hose set alkalis + acids

For acidic liquids and low-viscosity chemicals

Description:

The hose set is suitable for aggressive and non-flammable liquids, but also for food liquids. The hose is made of PVC with an embedded and galvanised steel wire helix (smooth inside and outside). The set is used for connection to the pumping station or nozzle.

Also available in special lengths on request

Features & advantages

Nominal diameter DN 19 (3/4")

PP hose connection

Pre-assembled hose connections and hose clamps

Food

Explosion protection

DN 19 (3/4")

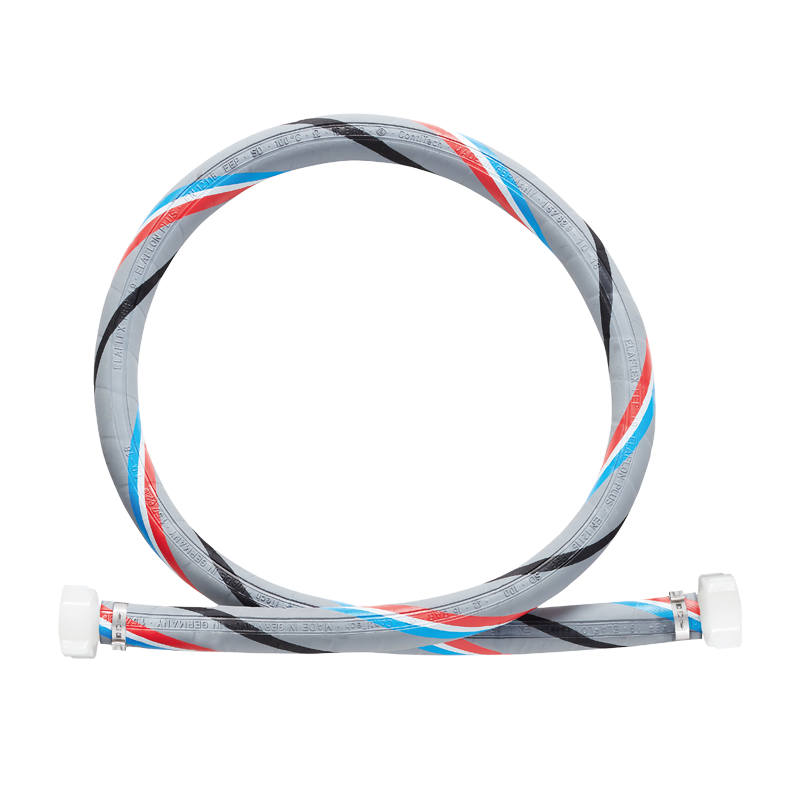

Hose set Ex-Pure

for watery and fatty foods

Description:

The hose set is suitable for aqueous and fatty foods. The hose is electrically conductive so that it can also be used in potentially explosive environments. The set is used for connection to the pump unit or the dispensing nozzle.

Also available in special lengths on request

Electrically conductive

Features & advantages

Hose connection: Tri-Clamp DN 32

Nominal width: DN 19 (3/4")

DN 19 (3/4")

2 m

Hose set for concentrated alkalis and acids

for highly chemical liquids and salts

Description:

The hose set is for concentrated alkalis + acids. The set is FDA and USP Class VI compliant. The set is used to connect to the pumping station or the dispensing nozzle.

Also available in special lengths on request

Suitable for filling or decanting chemicals, foodstuffs and hygiene products

Features & advantages

Nominal diameter DN 19 (3/4")

PVDF hose connection

Pre-assembled hose connections and hose clamps

Explosion protection

DN 19 (3/4")

2 m

Hose set for potentially explosive media

For aggressive and highly flammable liquids

Description:

The hose set is suitable for pure chemicals and potentially explosive liquids. The hose is electrically conductive so that it can also be used in potentially explosive environments. The set is used for connection to the pumping station or the dispensing nozzle.

Also available in special lengths on request

Electrically conductive

Features & advantages

Hose connection: 1 1/4" female thread

Nominal diameter: DN 19 (3/4")

Pre-assembled hose connections

Complies with EU regulations 10/2011 and 1935/2004

Ø 30 mm

Aluminium

Hub, motor side

for B70V 120.1

Description:

If the motor is provided by the customer, the hub must also be ordered in accordance with the shaft diameter.

Material made of aluminium

Features & advantages

Shaft diameter: Ø 24 mm / Ø 25 mm / Ø 28 mm / Ø 30 mm

Explosion protection

Ø 19 mm

Aluminium

Hub, motor side

for explosion-protected B70V 12.1 to 75.1

Description:

If the motor is provided by the customer, the hub must also be ordered in accordance with the shaft diameter.

Material made of aluminium

Features & advantages

Shaft diameter: Ø 19 mm / Ø 24 mm

Labelling: Ex II 2 G Ex h IIC T6...T4 Gb

Ø 14 mm

Aluminium

Hub, motor side

for B70V 12.1 to 75.1

Description:

If the motor is provided by the customer, the hub must also be ordered in accordance with the shaft diameter.

Material made of aluminium

Features & advantages

Shaft diameter: Ø 14 mm / Ø 19 mm / Ø 24 mm / Ø 28 mm

Stainless steel

IBC traverse

for drum pumps and eccentric screw pumps B70

Description:

The IBC lifting beam is used to safely remove and install the pumping units or the double diaphragm pump.

Suitable for drum pumps, B70 progressive cavity pumps and diaphragm pumps

Includes transport straps for lifting vehicles and tensioning hooks for fixing to the container

Features & advantages

Compatible with all standard IBC containers

Material: stainless steel

Clamping hook: galvanised steel

for drum pumps / B70 version, guide sleeve with Ø 55 mm made of plastic

Stainless steel (1.4571)

Inline protection

for pumping station B70V 120.1

Description:

The inliner protection is suitable for attachment to the pump foot. It protects sensitive drum inliners and bags from damage.

Explosion protection

DN 25 (1")

max. 10 bar

Mineral oil hose

for oils such as diesel, machine oils and heating oils

Description:

The hose is suitable for mineral oil products of all types and super up to 50% aromatics and methanol content. The inner rubber is made of NBR and the outer rubber of either CR (chloroprene) or NBR. The hose is electrically conductive so that it can also be used in potentially explosive environments.

Also available in special lengths on request

Nominal width: DN 13 / DN 19 / DN 25 / DN 32 / DN 38 / DN 50

Features & advantages

Operating pressure up to max. 16 bar

Colour coding: "Yellow"