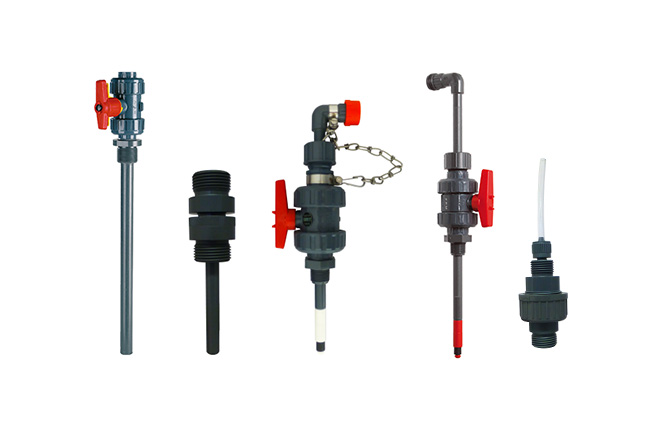

Inoculation sites

Inoculation of the conveyed chemical

The injection point is a fitting with which the dosing medium is introduced into a pressurised system. A non-return valve with a spring-loaded ball (type R) or a valve hose (type S) ensures that no process medium can flow backwards to the dosing pump during normal dosing operation and during process-related downtimes. Injection points should be equipped with a shut-off valve if possible. This allows the dosing system, including the non-return valve, to be disconnected from the pressurised system, e.g. for maintenance. In addition, the shut-off valve should be closed during longer downtimes because the tightness of the non-return valve could be impaired by contamination or wear.

Features & advantages

- Flow rate 70 - 2600 l/h

- Opening pressure 0.2 - 1.1 bar

- System pressure PN10 or PN16 (special versions up to PN160)

- Type S: Pre-tensioned hose ensures extremely fine spraying of the chemical during the dosing stroke

- Type SAH: Dismantling of the injection tube possible under system pressure

- Type SKD: Self-cleaning due to constantly moving injection tube in the main flow

- The injection tube allows the dosing chemical to be injected into the centre of the pipeline and ensures good mixing

- the non-return function (type R and type S) prevents liquid from running backwards from the pressurised system to the dosing pump

- a shut-off valve makes it possible to separate the dosing system from the pressurised system and provides a safe shut-off during longer downtimes

- a cooling pipe is used to dissipate heat when dosing into systems with high temperatures, but the dosing line is made of plastic

- Various transitions from the injection point to the dosing line are possible, e.g. to a hose, to a rigid line or via a flange