Product overview

Product innovations

New

Battery

Pump tube set

Canister - Pumping unit set 20/30 L

Ideal for 20/30 litre canisters

Canister pump tubes

The new battery-powered canister pump offers a clean and safe solution for emptying canisters quickly. With a replaceable battery and quick-release fastener, the pump remains flexible and easy to use. Perfect for use on different containers without causing contamination.

Highlights at a glance:

Simple and quick change of the battery-powered drive unit

Can be used anywhere without a power source

No contamination of the media and the surrounding area

Quick and easy to use thanks to lightweight equipment

Ergonomic filling

Infinitely variable to reduce the risk of accidents caused by splashing

precise filling/dosing of small quantities possible

Canister pumps

for clean and fast emptying of canisters & small drums

Various lengths available: 440 mm, 500 mm, 700 mm

Flexible hose set with ball valve

precise filling/dosing of small quantities possible

New

Battery

Complete set

Battery pump set - Universal

The versatile helper for your chemical applications

With the "Universal" B2 Battery pump set, you have a flexible and powerful partner for dispensing liquid fertilisers, light acids and alkalis, neutral liquids as well as low-viscosity oils and diesel. Ideally suited for small containers such as canisters or hobbocks, this set enables you to work efficiently and conserve resources. Perfect for anyone who needs flexibility and reliability when handling chemicals.

Highlights at a glance:

Simple and quick change of the battery-powered drive unit

Can be used anywhere without a power source

No contamination of the media and the surrounding area

Quick and easy to use thanks to lightweight equipment

Ergonomic filling

Infinitely variable to reduce the risk of accidents due to splashing

precise filling/dosing of small quantities possible

Battery

Complete set

Battery pump set - Robust

The versatile helper for your chemical applications

With the "Robust" B2 Battery pump set, you have a flexible and powerful partner for dispensing oil-based lubricants (PPS), low-viscosity oil products, diesel and heating oil. Ideally suited for small containers such as canisters or hobbocks, this set enables you to work efficiently and conserve resources. Perfect for anyone who needs flexibility and reliability when handling oils.

Highlights at a glance:

Simple and quick change of the battery-powered drive

Can be used anywhere without a power source

No contamination of the media and the surrounding area

Quick and easy to use thanks to lightweight equipment

Ergonomic filling

Infinitely variable to reduce the risk of accidents due to splashing

Precise filling / dosing of small quantities possible

New

Battery

Complete set

Battery pump set - Universal

The versatile helper for your chemical applications

With the "Universal" B2 Battery pump set, you have a flexible and powerful partner for dispensing liquid fertilisers, light acids and alkalis, neutral liquids as well as low-viscosity oils and diesel. Ideally suited for small containers such as canisters or hobbocks, this set enables you to work efficiently and conserve resources. Perfect for anyone who needs flexibility and reliability when handling chemicals.

Highlights at a glance:

Simple and quick change of the battery-powered drive unit

Can be used anywhere without a power source

No contamination of the media and the surrounding area

Quick and easy to use thanks to lightweight equipment

Ergonomic filling

Infinitely variable to reduce the risk of accidents due to splashing

precise filling/dosing of small quantities possible

New

Battery

Pump tube set

Canister - Pumping unit set 20/30 L

Ideal for 20/30 litre canisters

Canister pump tubes

The new battery-powered canister pump offers a clean and safe solution for emptying canisters quickly. With a replaceable battery and quick-release fastener, the pump remains flexible and easy to use. Perfect for use on different containers without causing contamination.

Highlights at a glance:

Simple and quick change of the battery-powered drive unit

Can be used anywhere without a power source

No contamination of the media and the surrounding area

Quick and easy to use thanks to lightweight equipment

Ergonomic filling

Infinitely variable to reduce the risk of accidents caused by splashing

precise filling/dosing of small quantities possible

Canister pumps

for clean and fast emptying of canisters & small drums

Various lengths available: 440 mm, 500 mm, 700 mm

Flexible hose set with ball valve

precise filling/dosing of small quantities possible

Chemical-free & safe

Efficient & low maintenance

Modular & flexible

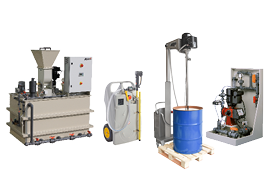

EASYCHLORGEN T - Safe sodium hypochlorite system for reliable water disinfection

On-site disinfection without risk

Maximum safety and efficiency in water treatment

Whether for drinking water, process water or swimming pool water – the EASYCHLORGEN T produces fresh, stable sodium hypochlorite on-site. This ensures reliable and standard-compliant disinfection at all times without the need to transport and store dangerous chemicals.

The advantages at a glance

✅ Safety and health protection – no need to handle dangerous chemicals: the only starting substance required is salt. Comes with integrated hydrogen detection.✅ Cost effective – achieve a stable chlorine content that lasts months without the need for any additives; vacuum dosing technology ensures long maintenance intervals✅ Process reliability – automatic fault detection with clear warnings; the system is self-regulating over a wide operating range without unnecessary shutdowns✅ Simple operation – touchscreen control, multilingual menus, intuitive handling✅ Flexibility – various capacity ranges (250–2000 g/h), modular structure, can be combined with various tank sizes✅ Low-maintenance – few wearing parts, easy to clean, no encrusting on the dosing points

Typische Anwendungsbereiche

Waterworks and municipal drinking water supplies

The food industry (e.g. fruit and vegetable washing facilities, dairies and breweries

Cooling water and process water treatment

Industrial wastewater treatment

Swimming pools and leisure centres

Maximum process reliability

Simple operation

Efficient & low maintenance

EASYZON H - Chlorine dioxide systems for safe and precise disinfection

Safe chlorine dioxide production on site

Pressureless and safe production of chlorine dioxide

The EASYZON H is the compact complete solution for the safe on-site production of chlorine dioxide for water treatment, the food industry and process water. The system works fully automatically under Vacuum - for maximum user safety, high dosing accuracy and constant disinfection performance even at high pH values.

Your benefits at a glance

✅ Safe handling under Vacuum - acid and chlorite are automatically drawn from the storage containers and mixed without any pressurised systems or risk of leakage.

✅ High process reliability - The vacuum process allows significantly longer suction distances than conventional Dosing pumps, ideal for flexible system concepts.

✅ Precise control of the chemical flows - integrated flow meters regulate the volume flows precisely; the product concentration can be set between 250 - 2000 mg/l ClO₂ as required.

✅ Automatic replenishment - via level sensors in the integrated 8-litre product tank; ensures continuous disinfection readiness.

Intuitive control - via touchscreen, with clear system visualisation, multilingual menus and password-protected user levels.

✅ Real-time monitoring & alarm management - forwarding of alarm messages via Modbus TCP/IP or optionally via SMS telemetry.

Efficiency & economy - low operating costs, minimised maintenance intervals and high energy efficiency significantly reduce life cycle costs

Typical areas of application

Legionella prevention in drinking water and cooling systems

CIP disinfection in the Foodstuffs and beverage industry

Biocide treatment of cooling towers and recooling plants

Disinfection: of municipal drinking water and process water

Secondary disinfection in public buildings

Food treatment to extend shelf life

Odour control in waste and process systems

Why EASYZON H?

The EASYZON H combines maximum safety, precise control and full compliance with standards in one system. Thanks to its modular design and optional skid version, the system can be seamlessly integrated into existing processes - from small waterworks to large industrial plants.

Maximum process reliability

Simple operation

Efficient & low maintenance

EASYZON L - Chlorine dioxide systems for safe and precise disinfection

Safe chlorine dioxide production on site

Pressureless and safe production of chlorine dioxide

The EASYZON L is the compact complete solution for the safe on-site production of chlorine dioxide for water treatment, the food industry and process water. The system works fully automatically under Vacuum - for maximum user safety, high dosing accuracy and constant disinfection performance even at high pH values.

Your benefits at a glance

✅ Safe handling under Vacuum - acid and chlorite are automatically drawn from the storage containers and mixed without any pressurised systems or risk of leakage.

✅ High process reliability - The vacuum process allows significantly longer suction distances than conventional Dosing pumps, ideal for flexible system concepts.

✅ Precise control of the chemical flows - integrated flow meters regulate the volume flows precisely; the product concentration can be set between 250 - 2000 mg/l ClO₂ as required.

✅ Automatic replenishment - via level sensors in the integrated 8-litre product tank; ensures continuous disinfection readiness.

Intuitive control - via touchscreen, with clear system visualisation, multilingual menus and password-protected user levels.

✅ Real-time monitoring & alarm management - forwarding of alarm messages via Modbus TCP/IP or optionally via SMS telemetry.

Efficiency & economy - low operating costs, minimised maintenance intervals and high energy efficiency significantly reduce life cycle costs

Typical areas of application

Legionella prevention in drinking water and cooling systems

CIP disinfection in the Foodstuffs and beverage industry

Biocide treatment of cooling towers and recooling plants

Disinfection: of municipal drinking water and process water

Secondary disinfection in public buildings

Food treatment to extend shelf life

Odour control in waste and process systems

Why EASYZON L?

The EASYZON L combines maximum safety, precise control and full compliance with standards in one system. Thanks to its modular design and optional skid version, the system can be seamlessly integrated into existing processes - from small waterworks to large industrial plants.

Maximum process reliability

Simple operation

Efficient & low maintenance

EASYZON M - Chlorine dioxide systems for safe and precise disinfection

Safe chlorine dioxide production on site

Pressureless and safe production of chlorine dioxide

The EASYZON M is the compact complete solution for the safe on-site production of chlorine dioxide for water treatment, the food industry and process water. The system works fully automatically under Vacuum - for maximum user safety, high dosing accuracy and constant disinfection performance even at high pH values.

Your benefits at a glance

✅ Safe handling under Vacuum - acid and chlorite are automatically drawn from the storage containers and mixed without any pressurised systems or risk of leakage.

✅ High process reliability - The vacuum process allows significantly longer suction distances than conventional Dosing pumps, ideal for flexible system concepts.

✅ Precise control of the chemical flows - integrated flow meters regulate the volume flows precisely; the product concentration can be set between 250 - 2000 mg/l ClO₂ as required.

✅ Automatic replenishment - via level sensors in the integrated 8-litre product tank; ensures continuous disinfection readiness.

Intuitive control - via touchscreen, with clear system visualisation, multilingual menus and password-protected user levels.

✅ Real-time monitoring & alarm management - forwarding of alarm messages via Modbus TCP/IP or optionally via SMS telemetry.

Efficiency & economy - low operating costs, minimised maintenance intervals and high energy efficiency significantly reduce life cycle costs

Typical areas of application

Legionella prevention in drinking water and cooling systems

CIP disinfection in the Foodstuffs and beverage industry

Biocide treatment of cooling towers and recooling plants

Disinfection: of municipal drinking water and process water

Secondary disinfection in public buildings

Food treatment to extend shelf life

Odour control in waste and process systems

Why EASYZON M?

The EASYZON M combines maximum safety, precise control and full compliance with standards in one system. Thanks to its modular design and optional skid version, the system can be seamlessly integrated into existing processes - from small waterworks to large industrial plants.

New

Battery

Pump tube

Pump tube LubeDrive

for lubricating greases and gear oils

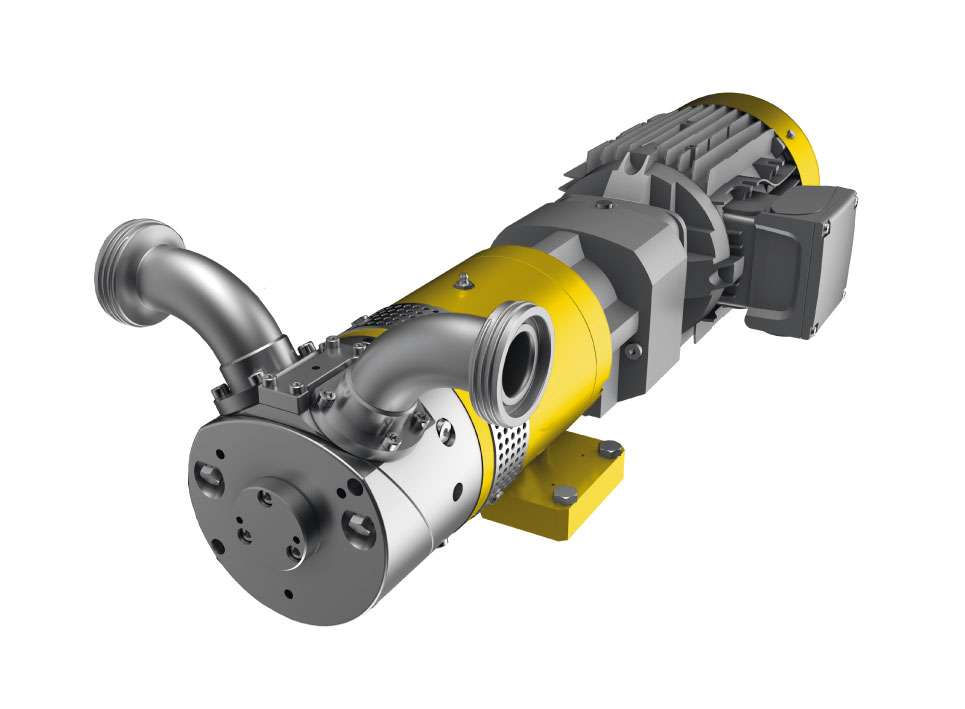

The first battery-operated progressive cavity pump for grease & oil - without compromise, without limits

Compact pumping unit for maximum independence for centralised lubrication systems & gear oil filling

The LubeDrive pumping unit is the perfect partner for mobile maintenance applications in construction, industry and agricultural technology. Where compressed air is lacking and hand pumps are not sufficient, the LubeDrive impresses with its efficiency, flexibility and ease of use.

For maintenance teams with responsibility - not for compromises

Workshop personnel, service technicians and system operators know the problem: lubrication points that are difficult to access, no compressed air within reach, high effort required. With the LubeDrive pump unit, all you need is a cordless screwdriver - for simple, fast filling directly at the point of use.

Simple to use - powerful in performance

This pumping unit is ideal for anyone who already owns accessories or uses customised system solutions. It can be seamlessly integrated into existing equipment and ensures quiet, powerful operation - with no effort at all.

✅ Advantages of the LubeDrive pump unit:

First-to-market technology: Unique solution without a comparable product

Cordless screwdriver instead of compressor: Mobile, flexible, ready for use at any time

Ideal for OEMs and industrial dealers: Customised for professional use

Delivery up to 2 kg/min: Efficiency gains with every work step

Quieter & faster than pneumatic alternatives

Universally applicable for greases (up to NLGI-2) and gear oils

Compatible with 10-60 kg containers

Low-maintenance & user-friendly design

New

Battery

Pump tube set

Pump unit set LubeDrive

Filling pump for lubricating greases and gear oils

The mobile complete solution for grease & gear oil - quiet, efficient, completely mains-independent

Mobile complete set for workshop & construction site - without electricity, without compressed air

Whether on the construction site, in the workshop or in the field: The LubeDrive pumping unit set delivers lubricants to where they are needed - quickly, quietly and powerfully. Ideal for centralised lubrication systems and gearbox oil filling.

Developed for maintenance technicians who need flexibility

In agricultural and construction machinery technology, every minute counts. With the LubeDrive set, vehicles and systems can be filled directly on site - without any manual force or compressed air. Workshops in particular benefit from a simple, ready-to-use solution.

No more inefficient pumping

The set combines robust technology with maximum user-friendliness. Simply connect the cordless screwdriver - and work more efficiently than ever before. Quieter and faster than pneumatic systems, significantly less effort than with hand pumps.

✅ Your benefits with the LubeDrive pump set:

Operation with a standard cordless screwdriver - no special tools required

Without compressed air & electricity: Maximum mobility in any application environment

Up to 2 kg/min pumping capacity: Saves valuable working time

For greases up to NLGI-2 & gear oils

Compatible with 10-60 kg containers

Noticeably quieter than pneumatic systems

Robust design for rough everyday working conditionsFor construction and agricultural vehicles in mobile useDeveloped for workshops and maintenance teams

New

Battery

Pump tube set

Canister - Pumping unit set 20/30 L

Ideal for 20/30 litre canisters

Canister pump tubes

The new battery-powered canister pump offers a clean and safe solution for emptying canisters quickly. With a replaceable battery and quick-release fastener, the pump remains flexible and easy to use. Perfect for use on different containers without causing contamination.

Highlights at a glance:

Simple and quick change of the battery-powered drive unit

Can be used anywhere without a power source

No contamination of the media and the surrounding area

Quick and easy to use thanks to lightweight equipment

Ergonomic filling

Infinitely variable to reduce the risk of accidents caused by splashing

precise filling/dosing of small quantities possible

Canister pumps

for clean and fast emptying of canisters & small drums

Various lengths available: 440 mm, 500 mm, 700 mm

Flexible hose set with ball valve

precise filling/dosing of small quantities possible

New

Battery

Complete set

Battery pump set - Universal

The versatile helper for your chemical applications

With the "Universal" B2 Battery pump set, you have a flexible and powerful partner for dispensing liquid fertilisers, light acids and alkalis, neutral liquids as well as low-viscosity oils and diesel. Ideally suited for small containers such as canisters or hobbocks, this set enables you to work efficiently and conserve resources. Perfect for anyone who needs flexibility and reliability when handling chemicals.

Highlights at a glance:

Simple and quick change of the battery-powered drive unit

Can be used anywhere without a power source

No contamination of the media and the surrounding area

Quick and easy to use thanks to lightweight equipment

Ergonomic filling

Infinitely variable to reduce the risk of accidents due to splashing

precise filling/dosing of small quantities possible

Battery

Complete set

Battery pump set - Robust

The versatile helper for your chemical applications

With the "Robust" B2 Battery pump set, you have a flexible and powerful partner for dispensing oil-based lubricants (PPS), low-viscosity oil products, diesel and heating oil. Ideally suited for small containers such as canisters or hobbocks, this set enables you to work efficiently and conserve resources. Perfect for anyone who needs flexibility and reliability when handling oils.

Highlights at a glance:

Simple and quick change of the battery-powered drive

Can be used anywhere without a power source

No contamination of the media and the surrounding area

Quick and easy to use thanks to lightweight equipment

Ergonomic filling

Infinitely variable to reduce the risk of accidents due to splashing

Precise filling / dosing of small quantities possible

Overview of all Lutz products

Our complete range

Filter

Filter pressure reducer

for Lutz Compressed air motors and Diaphragm pumps DMP 1/4 "to 2"

Description:

Filter pressure reducer with pressure gauge for setting the operating pressure.

Inlet pressure max. 16 bar

Ambient temperature max. 60°C

Features & advantages

Filter element 5 µm, Cellpor and 40 ?m, sintered bronze

Housing made of die-cast zinc and aluminium

Diaphragm and seals made of NBR

electric

Internally ventilated

Universal motor MI 4 / MI 4-E

MI4

Description

The MI 4 motor is suitable for non-flammable, aqueous to slightly viscous liquids. Depending on the application, various motors with the appropriate voltage are available, which you can combine with the pumping station at any time. This gives you flexibility at all times and conserves important resources.

Optionally with speed controller to adjust the delivery rate

Internally ventilated motor

Features & advantages

Quick and easy disassembly

Light and easy to handle

Powerful motor

electric

Complete set

Pump set - Mineral oils

for oils and lubricants

Description:

The pump set is suitable for low-viscosity, aggressive and non-flammable media. Perfectly suited for the extraction or decanting of mineral oils.

Examples of media: Diesel, heating oil, hydraulic oil, machine oil and engine oil etc.

Pumping unit equipped with Lutz Original handwheel

Suitable for filling or decanting alternative fuels

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

Optimised drum emptying

Universally resistant ETFE shaft bearing

Maintenance without special tools

Sealing modules of the sealless (DL) pump can be replaced

MAGDOS LB

MAGDOS LB - Simple dosing pump of the latest generation!

The MAGDOS LB solenoid-driven diaphragm dosing pump is a cost-effective alternative for simple, continuous dosing tasks. It is particularly suitable for water treatment and the process industry. The MAGDOS LB is available in seven performance ranges. Double ball valves ensure precise dosing. The dosing capacity can be adjusted continuously from 0 - 100 % via the stroke frequency of the dosing pump. The MAGDOS LB is a compact solution, reduced to the most important elements for reliable dosing.

Features & advantages

Output range 0.36 - 13 l/h, up to 16 bar

Wide-range power supply 100 - 240 V, 50/60 Hz, IP65

Dosing head ventilation (plastic version)

Suitable for wall and floor mounting

Material versions PVC, PP, PVDF, stainless steel

Dosing capacity continuously adjustable from 0 - 100

CSA and UL certified

Motor MA II 5

Description

The MA II 5 motor is suitable for aqueous to slightly viscous, aggressive and outgassing liquids. Depending on the application, various motors with the appropriate voltage are available, which you can combine with the pump unit at any time. This gives you flexibility at all times and saves important resources.

Optionally with undervoltage release

Externally ventilated motor

Also available as an acid protection version

Features & benefits

Double insulation with protective conductor connection

Optimised cooling air routing

Double-walled housing protects the internal parts from corrosion

Robust and solid construction

PP

DN 19 (3/4")

PP hose connection

with 1" internal thread connection

Description:

The hose connection connects the delivery hoses to Pump tubes and the double diaphragm pumps. When using a double diaphragm pump, a suitable reducing nipple must be used in addition to the hose connection

Special connections are available on request

Properties & advantages

Nominal diameter (DN): DN 19 x G 1" female thread

Material: PP

Foodstuffs

Explosion protection

DN 25 (1")

Universal chemical hose

for chemicals, food and hygiene products

Description:

The hose is suitable for pure chemicals, cosmetics, photographic chemicals, paints and adhesives, detergents and cleaning agents, hygiene products, as well as food and luxury foods. It is FDA and USP Class VI compliant and is electrically conductive so that it can also be used in potentially explosive environments.

Also available in special lengths on request

Nominal width: DN 13 / DN 19 / DN 25 / DN 32 / DN 38 / DN 50

Features & advantages

Operating pressure up to max. 16 bar

Colour coding: "blue/white/blue".

Complies with EU regulations 10/2011 and 1935/2004

Underpressure max 0.9 bar

New

Battery

Pump tube set

Pump unit set LubeDrive

Filling pump for lubricating greases and gear oils

The mobile complete solution for grease & gear oil - quiet, efficient, completely mains-independent

Mobile complete set for workshop & construction site - without electricity, without compressed air

Whether on the construction site, in the workshop or in the field: The LubeDrive pumping unit set delivers lubricants to where they are needed - quickly, quietly and powerfully. Ideal for centralised lubrication systems and gearbox oil filling.

Developed for maintenance technicians who need flexibility

In agricultural and construction machinery technology, every minute counts. With the LubeDrive set, vehicles and systems can be filled directly on site - without any manual force or compressed air. Workshops in particular benefit from a simple, ready-to-use solution.

No more inefficient pumping

The set combines robust technology with maximum user-friendliness. Simply connect the cordless screwdriver - and work more efficiently than ever before. Quieter and faster than pneumatic systems, significantly less effort than with hand pumps.

✅ Your benefits with the LubeDrive pump set:

Operation with a standard cordless screwdriver - no special tools required

Without compressed air & electricity: Maximum mobility in any application environment

Up to 2 kg/min pumping capacity: Saves valuable working time

For greases up to NLGI-2 & gear oils

Compatible with 10-60 kg containers

Noticeably quieter than pneumatic systems

Robust design for rough everyday working conditionsFor construction and agricultural vehicles in mobile useDeveloped for workshops and maintenance teams

electric

Drum pump

Drum pumps - Mineral oils

for oils and cooling lubricants

Description:

The drum pump is suitable for low-viscosity, aggressive and non-flammable media. Perfectly suited for the removal or decanting of mineral oils.

Examples of media: Diesel, heating oil, hydraulic oil, machine oil and engine oil etc.

Pumping unit equipped with Lutz Original handwheel

Suitable for filling or decanting alternative fuels

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

Optimised drum emptying

Universally resistant ETFE shaft bearing

Maintenance without special tools

Sealing modules of the sealless (DL) pump can be replaced

Explosion protection

electric

Drum pump

Drum pumps - Solvent

for highly flammable hydrocarbons

Description:

The drum pump is suitable for low-viscosity, flammable and highly flammable hydrocarbons. Perfectly suited for the removal or decanting of solvents.

Optionally available with Ex plug

Pumping unit equipped with Lutz original handwheel

Suitable for filling or transferring alternative fuels, oils and flammable liquids

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

Highly resistant high-grade carbon shaft bearing

Maintenance without special tools

Sealing modules of the sealless (DL) pump can be replaced

Approved in accordance with ATEX Directive 2014/34/EU, category 1/2

MAGDOS LD

MAGDOS LD - Easy handling and space-saving!

The MAGDOS LD plays an important role in the reliable and precise dosing of liquids in process sequences and is available in seven performance ranges. Double ball valves ensure exact dosing. The stroke frequency can be adjusted manually or via external control contacts to adapt the dosing capacity.

The compact dosing pump can be integrated into any dosing system in a very space-saving manner thanks to its minimal mounting surface and can also be installed in three different positions, upright or horizontal, without the need for additional aids. left or right orientated on the wall.

Features & advantages

Output range 0.36 - 13 l/h, up to 16 bar

Power supply 230 V ±10 %, 50/60 Hz, IP65 or 115 V ± 10 %, 50/60 Hz, IP65

Dosing head ventilation (plastic version)

Suitable for wall and floor mounting

Material versions PVC, PP, PVDF, stainless steel

Stroke frequency precisely adjustable with keypad

Graphic display

Pulse input (overshoot and undershoot)

Level input with pre-alarm and main alarm

Enable input for external start/stop

Calculation wizard for pulse operation available online

CSA and UL certified

electric

Drum pump

HC Wave

Drum pumps - Acids

for acidic liquids

Description:

The drum pump is suitable for corrosive, aqueous to slightly viscous media. Perfectly suited for the removal or decanting of acids.

Examples of media: Hydrochloric acid, battery acid, iron-III-chloride, phosphoric acid, chromic acid and citric acid etc.

Pumping unit equipped with Lutz original handwheel

Suitable for filling or decanting oils such as rapeseed oil and vegetable oil

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

Optimised drum emptying

Universally resistant PTFE shaft bearing

Maintenance without special tools

Sealing modules of the sealless (DL) pump can be replaced

Motor MA II 7

Description

The MA II 7 motor is suitable for aqueous to slightly viscous, aggressive and outgassing liquids. Depending on the application, various motors with the appropriate voltage are available, which you can combine with the pump unit at any time. This gives you flexibility at all times and saves important resources.

Optionally with undervoltage release

Externally ventilated motor

Features & benefits

Double insulation with protective conductor connection

Optimised cooling air routing

Double-walled housing protects the internal parts from corrosion

Robust and solid construction

Plastic

PP

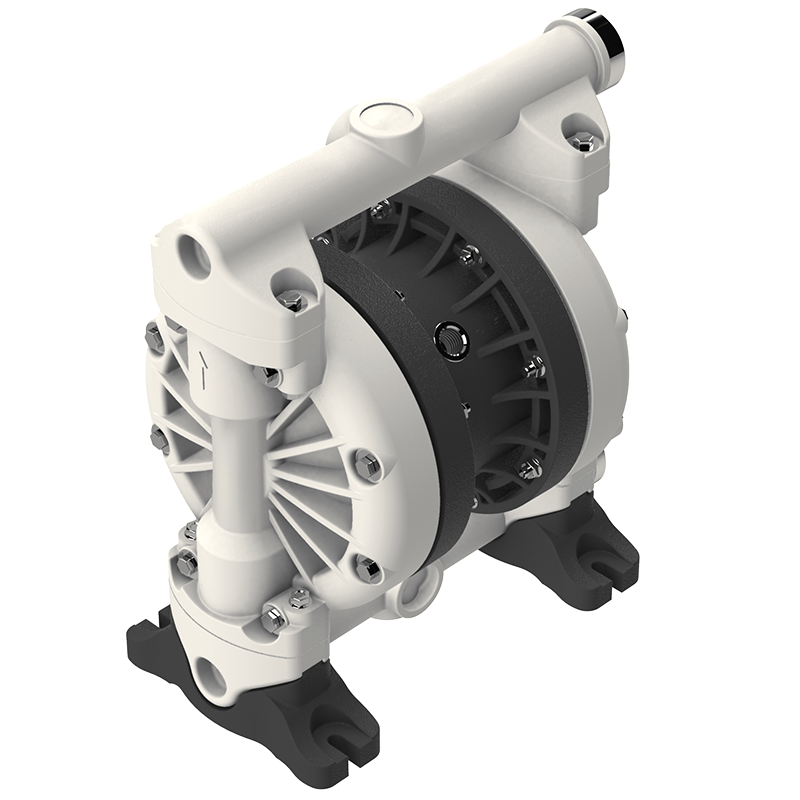

Compressed air

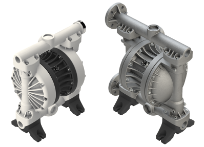

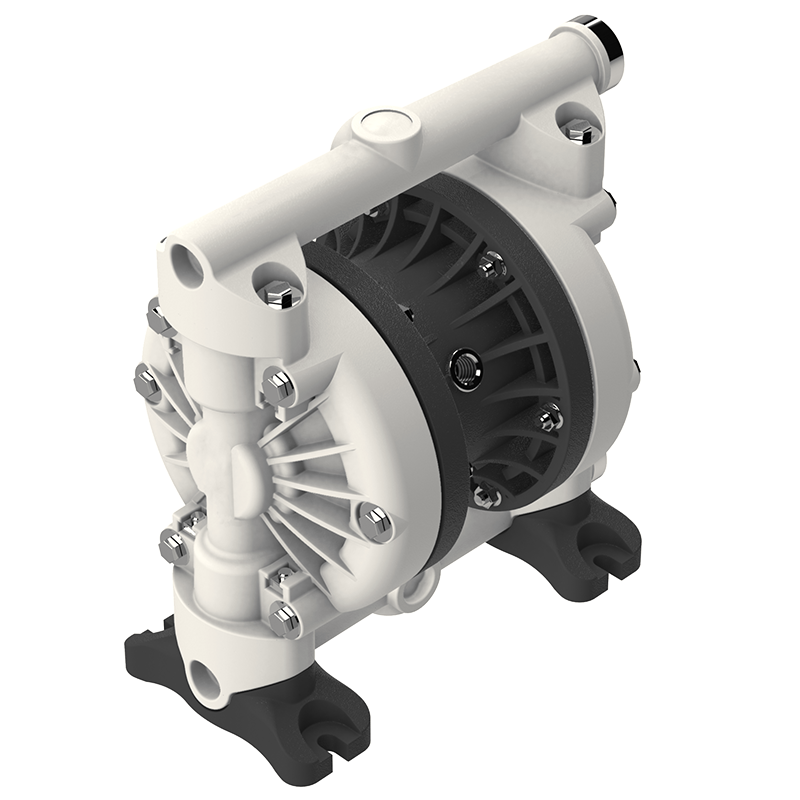

Double diaphragm pump DMP model 1/2" plastic

for drum, IBC and tank emptying

Description:

The double diaphragm pump is suitable for industrial applications as well as for drum, IBC and tank emptying.

Typical applications: 200 litre drums, paint circulation and feeding, feeding of chemicals, solvents, acids and liquid soap

Integrated silencer up to model size DMP 1"

highly resistant TFM (PTFE) diaphragms (modified PTFE)

Features & benefits

High hydraulic performance

Maintenance-optimised design and easy installation

Self-priming (even when dry)

Reinforced elastomers and thermoplastic diaphragm

Absolutely oil-free

blockage-free operation

Stainless steel shaft

Impeller

Pump tube aluminium

for mineral oils

Description:

The Lutz pumping station (aluminium) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application, various motors are available that you can combine with the pumping station at any time. This gives you flexibility at all times and saves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pumping unit equipped with Lutz Original handwheel

Suitable for filling or transferring alternative fuels

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped medium by lubricants

Optimised drum emptying

Universally resistant ETFE shaft bearing

Maintenance without special tools

Sealing modules of the mechanical seal (GLRD) or of the sealless (DL) pump interchangeable

DN 19 (3/4")

Hose clamp DN 19 (3/4")

Description:

The hose clamp is made of stainless steel and is suitable for attaching delivery hoses to the pump outlet or accessories.

The nominal diameter of the clamp corresponds to DN19 (3/4")

Features & advantages

Clamping range from 28.0 - 31.0 mm

Explosion protection

Stainless steel

Foot strainer for Eccentric screw pumps

for the Eccentric screw pumps B70V

Description:

The foot strainer can be used for progressive cavity pumps. By attaching the strainer to the pump foot, coarse impurities can be kept away from important components such as the drive.

For attaching to the pump base

Features & advantages

Prevents contamination in the pumping station by filtering it out

Material: Stainless steel (1.4571)

Basic

Motor MA II 3

Basic - 460 W - 230 V

Description

The MA II 3 motor is suitable for aqueous to slightly viscous, aggressive and outgassing liquids. Depending on the application, various motors with the appropriate voltage are available, which you can combine with the pump unit at any time. This gives you flexibility at all times and saves important resources.

Optionally with undervoltage release

Externally ventilated motor

Features & benefits

Double insulation with protective conductor connection

Optimised cooling air routing

Double-walled housing protects the internal parts from corrosion

Robust and solid construction

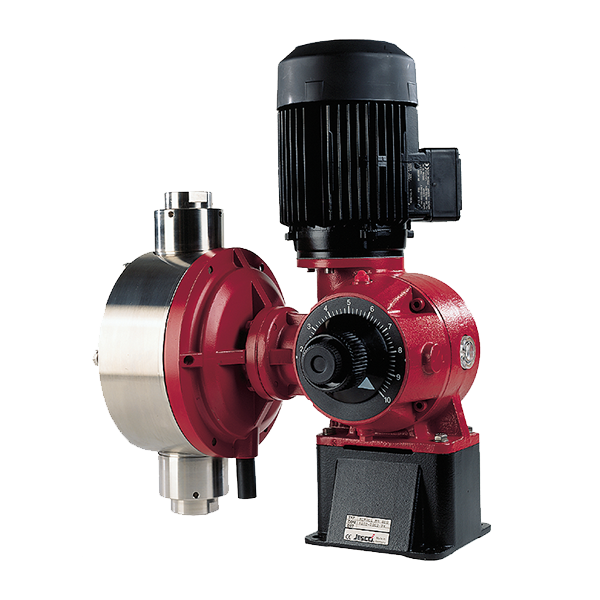

MEMDOS MR

MEMDOS MR/ZMR - Powerful motor-driven diaphragm dosing pump!Diaphragm dosing pumps in the MEMDOS MR series have been developed for a wide range of dosing technology applications. The dosing pumps are therefore used in the industrial sector, in process engineering and particularly frequently in water treatment and waste water treatment.

Features & advantages

robust, durable

Available as a single or double-head pump

Standard version single pumps left-sided dosing head arrangement

Capacity range 440 - 990 l/h, up to 5 bar

Double-head pumps diagonal dosing head arrangement

Capacity range 55 - 980 l/h per dosing head, up to 10 bar

Different materials and output ranges can be combined

Stroke length manually adjustable from 0 - 100

Electric actuator to control the stroke length (optional)

Materials: PVC, PP, PVDF and stainless steel

Suitable for frequency converter operation

Motors available in AC and three-phase versions

electric

Complete set

Pump set - B2 Vario Niro

for liquid lubricants and cleaning agents

Description:

The B2 Vario pump set is suitable for low-viscosity, aqueous to slightly viscous media. The set is suitable for dispensing small containers such as canisters, hobbocks and drums. The pump is flexible at all times and thus conserves important resources.

Infinitely variable speed controller for transferring and filling small quantities

Features & advantages

Sealless design (DL) conditionally dry-running safe

Infinitely variable

Powerful motor with improved service life

Easy to service and dismantle

Explosion protection

electric

Complete set

Pump set for Complete drainage - Solvent

for highly flammable hydrocarbons

Description:

The pump set is suitable for low-viscosity, flammable and highly flammable hydrocarbons and is perfect for dispensing or decanting solvents.

Examples of media: Ethanol, petrol, butanol, isopropanol, paraffin, methanol and petroleum, etc.

Pumping unit equipped with Lutz original handwheel

Suitable for emptying drums of alternative fuels, oils and flammable liquids

Features & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped liquid by lubricants

optimised drum emptying with a residual quantity of approx. 0.1 litre

No leaks if the pumping station is tilted or moved

Maximum product utilisation with reduced drum cleaning and disposal costs

Approved in accordance with ATEX Directive 2014/34/EU, category 1/2

Plastic

PP

Compressed air

Double diaphragm pump DMP model 1" plastic

for industrial applications as well as for drum, IBC and tank emptying

Description:

The double diaphragm pump is suitable for industrial applications and for emptying drums, IBCs and tanks.

Typical applications: Transfer from drums and containers, transfer of corrosive solutions and chemicals

Integrated silencer up to model size DMP 1"

highly resistant TFM (PTFE) diaphragms (modified PTFE)

Features & benefits

High hydraulic performance

Maintenance-optimised design and easy installation

Self-priming (even when dry)

Reinforced elastomers and thermoplastic diaphragm

Absolutely oil-free

blockage-free operation