Drum pumps for mixing and pumping

With emulsions, dispersions and suspensions that tend to sediment, it is often necessary to mix these liquids. Our mixing pump tube ensures that both work steps can be carried out during operation without having to be moved.

FILTER

Explosion protection

ROTOR

Pump tube Niro for mixing and pumping

for flammable liquids

Description:

The Lutz Pump tube (stainless steel) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application, various Motors are available, which you can combine with the Pump tube at any time. This gives you flexibility at all times and conserves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pump tubes equipped with Lutz Original handwheel

Suitable for mixing and pumping alternative fuels, oils and flammable liquids

Properties & advantages

Also available with Tri-Clamp connection

Optionally with electric or compressed air drive

Two functions (Mixing and pumping) in one device

No leaks when the Pump tube is tilted or moved

high mixing and delivery capacity for thorough homogenisation

Switching between the Mixing and pumping functions takes place without interrupting ongoing operation, which is made possible by a small lever on the handwheel

HC Wave

ROTOR

Pump tube PP for mixing and pumping

for low-viscosity acids

Description:

The Lutz Pump tube (PP) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application, various Motors are available, which you can combine with the Pump tube at any time. This gives you flexibility at all times and conserves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pump tubes equipped with Lutz Original handwheel

Suitable for mixing and pumping oils such as rapeseed oil and vegetable oil

Properties & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped medium by lubricants

two functions (pumping and pumping) in one device

no leaks if the Pump tube is tilted or moved

high mixing and conveying capacity for thorough homogenisation

Switching between the Mixing and pumping functions takes place without interrupting ongoing operation, which is made possible by a small lever on the handwheel

Stainless steel shaft

ROTOR

Pump tube PP for mixing and pumping

for low-viscosity alkaline solutions

Description:

The Lutz Pump tube (PP) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application, various Motors are available, which you can combine with the Pump tube at any time. This gives you flexibility at all times and saves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pump tubes equipped with Lutz Original handwheel

Suitable for mixing and pumping oils such as rapeseed oil and vegetable oil

Properties & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped medium by lubricants

Two functions (pumping and pumping) in one device

no leaks if the Pump tube is tilted or moved

high mixing and conveying capacity for thorough homogenisation

Switching between the Mixing and pumping functions takes place without interrupting ongoing operation, which is made possible by a small lever on the handwheel

Stainless steel shaft

Impeller

Pump tube PP for mixing and pumping

for low-viscosity alkaline solutions

Description:

The Drum pump is suitable for corrosive, aqueous to slightly viscous media. Depending on the application, various Motors are available, which you can combine with the Pump tube at any time. This gives you flexibility at all times and conserves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pump tubes equipped with Lutz Original handwheel

Suitable for mixing and pumping oils such as rapeseed oil and vegetable oil

Properties & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped medium by lubricants

two functions (pumping and pumping) in one device

no leaks if the Pump tube is tilted or moved

high mixing and conveying capacity for thorough homogenisation

Switching between the Mixing and pumping functions takes place without interrupting ongoing operation, which is made possible by a small lever on the handwheel

Foodstuffs

Explosion protection

ROTOR

Pump tube Niro for mixing and pumping - PURE

for Foodstuffs (PURE series)

Description:

The Lutz Mixing and pumping (stainless steel) PURE pump tube is suitable for aqueous and fatty Foodstuffs. Depending on the application, various Motors are available that you can combine with the Pump tube at any time. This gives you flexibility at all times and saves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pump tubes equipped with Lutz Original handwheel

For mixing and pumping alcohol-containing Foodstuffs, cosmetics and pharmaceutical products as well as flammable cleaning agents

Properties & advantages

Physiologically safe version

Connections: suitable for foodstuffs

High mixing and pumping capacity for thorough homogenisation

Two functions (Mixing and pumping) in one device

Approved according to FDA and Regulation (EC) 1935/2004

approved in accordance with ATEX Directive 2014/34/EU, category 1/2

HC Wave

Impeller

Pump tube PP for mixing and pumping

for low-viscosity acids

Description:

The Lutz Pump tube (PP) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application, various Motors are available, which you can combine with the Pump tube at any time. This gives you flexibility at all times and saves important resources.

Also available in special immersion depths from 200 - 2500 mm

Pump tubes equipped with Lutz Original handwheel

Suitable for mixing and pumping oils such as rapeseed oil and vegetable oil

Properties & advantages

Optionally with electric or compressed air drive

No lubricants and therefore no contamination of the pumped medium by lubricants

Two functions (pumping and pumping) in one device

no leaks if the Pump tube is tilted or moved

high mixing and conveying capacity for thorough homogenisation

Switching between the Mixing and pumping functions takes place without interrupting ongoing operation, which is made possible by a small lever on the handwheel

Drum pump MP-PP with Motor B 55-T-5 (120 V)

Suitable for mixing and pumping corrosive, aqueous to slightly viscous media in non-hazardous environments.

Examples of liquids: Emulsions, suspensions, dispersions, paints and varnishes, etc.

Properties:

Two functions (Pumping and Mixing and pumping) in one device

No grease filling in the Pump tubes

Modular, service-friendly design

Advantages:

Switching between pumping and mixing and pumping without repositioning during operation via a small lever below the handwheel

High mixing and pumping capacity for thorough homogenisation and fast emptying

No contamination of the pumped medium by lubricants

Note: Always mix with drum cover

Drum pump MP-Niro with Motor B 55-T-5 (120 V)

Description: Compact.

Compact. Versatile. Ideal for mixing and pumping corrosive media.

The MP-Niro Drum pump is the perfect solution for the reliable mixing and pumping of corrosive, aqueous to slightly viscous liquids in non-hazardous environments. Its combination of mixing unit and pumping function makes it particularly efficient for applications with emulsions, dispersions, paints or varnishes. Thanks to the robust stainless steel pump tube, low-maintenance design and user-friendly switchover mechanism, this drum pump is ideal for industrial applications in laboratories, chemical plants or production facilities. Typical pumping media:emulsions, suspensions, dispersions, paints, varnishes, cleaning fluids

Two functions ("Pumping" and "Mixing and pumping") in one device

No grease filling in the Pump tube

Modular, service-friendly design

Properties & advantages:

Switch between "Pumping" and "Mixing and pumping" without repositioning during operation via a small lever below the handwheel

High mixing and delivery capacity for thorough homogenisation and fast emptying

No contamination of the pumped medium by lubricants

Note: Always mix with drum cover

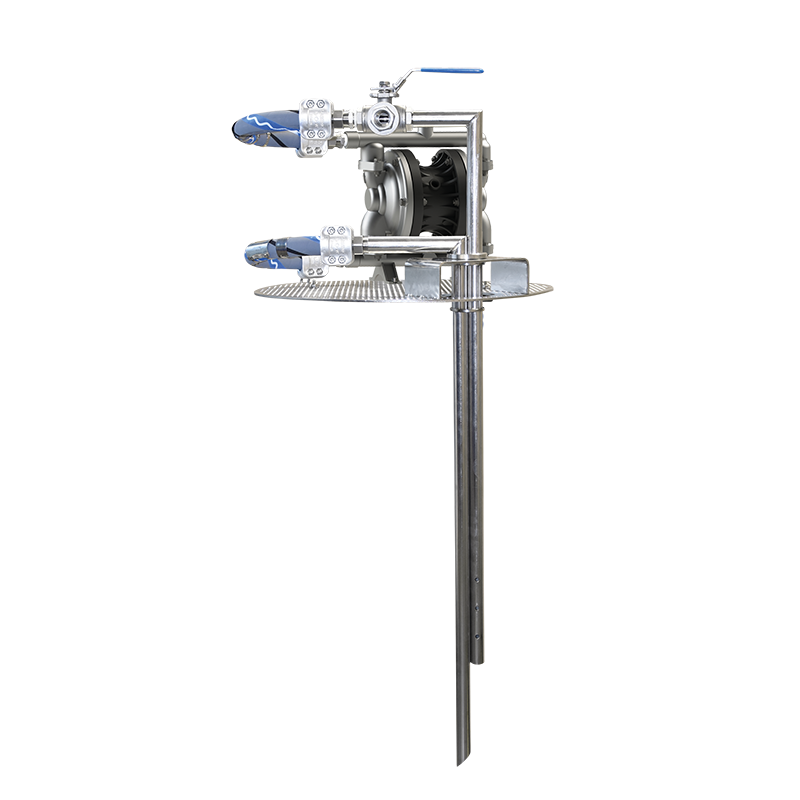

Diaphragm pumps mixing system

Mixing and pumping (explosion-proof)

Description:

For liquids that need to be mixed before processing and then pumped or that also contain small solids, the new Diaphragm pump mixing system with an integrated compressed air-driven double Diaphragm pump is the perfect solution. The mixing and pumping process takes place via a suction and mixing pipe and a 3-way valve. The pre-assembled system is ready for immediate use in just a few simple steps and is also suitable for potentially explosive liquids.

Mixing and pumping integrated in one system

Examples of media: Paints and varnishes, emulsions, dispersions, suspensions, water/oil mixtures, liquids with increased Viscosity and solids content

Properties & advantages

Quick installation and time savings thanks to simple handling

Compact design

Base plate offers good stability on the container lid

Easy to insert into the 2" bunghole of the container using a balancer or overhead crane

No additional mixer required