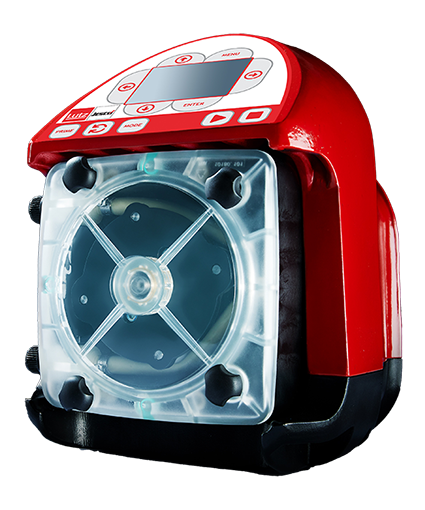

Reliable peristaltic pumps for demanding industries

The peristaltic pumps of the PERIDOS FXM are suitable for industries that require durability, process reliability, and low total cost of ownership:

- Water and wastewater treatment

- Chemicals industry

- Food and beverage industry

- Paper and pulp industry

- Mining and construction industry

- Agriculture / agricultural engineering

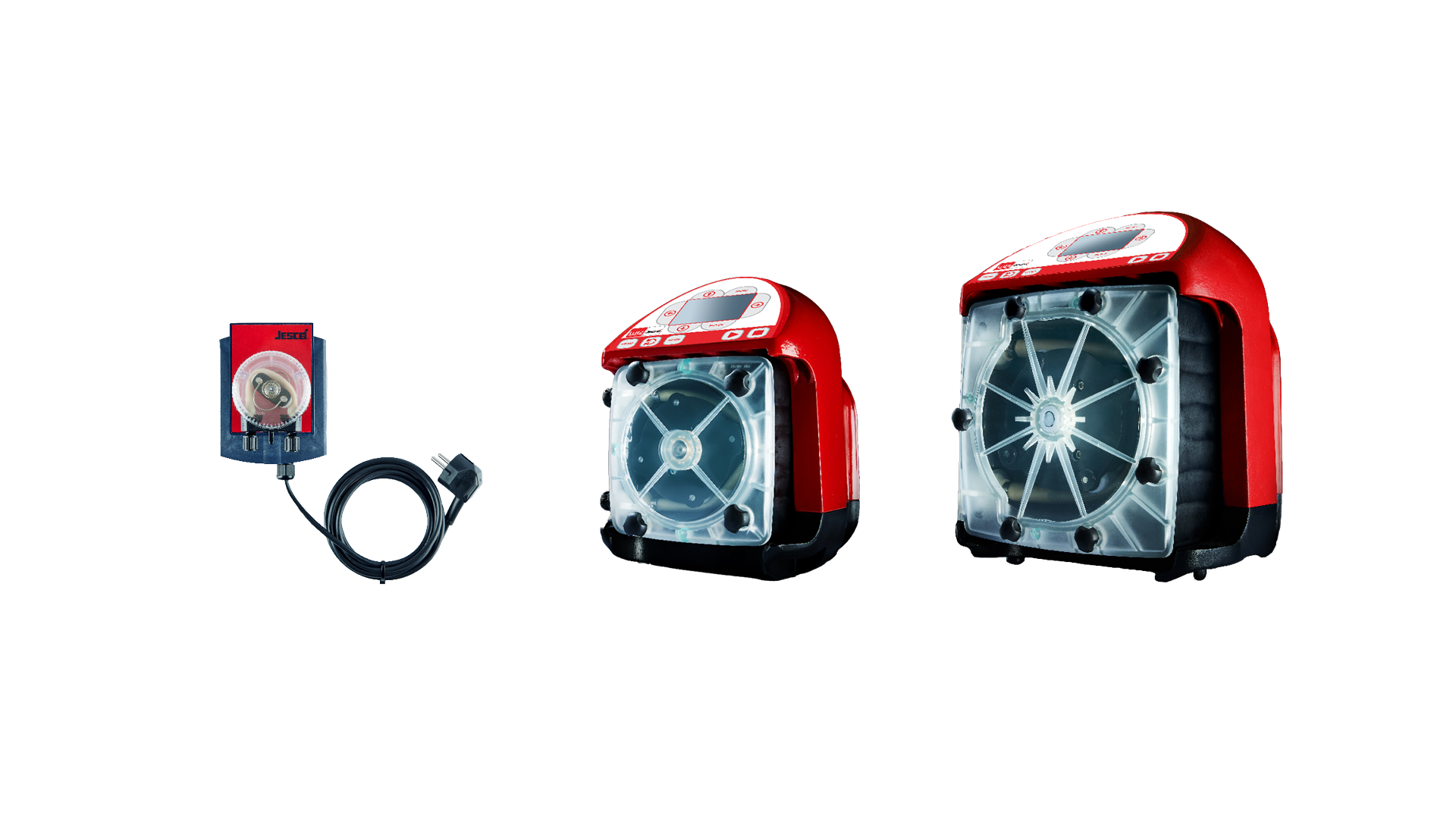

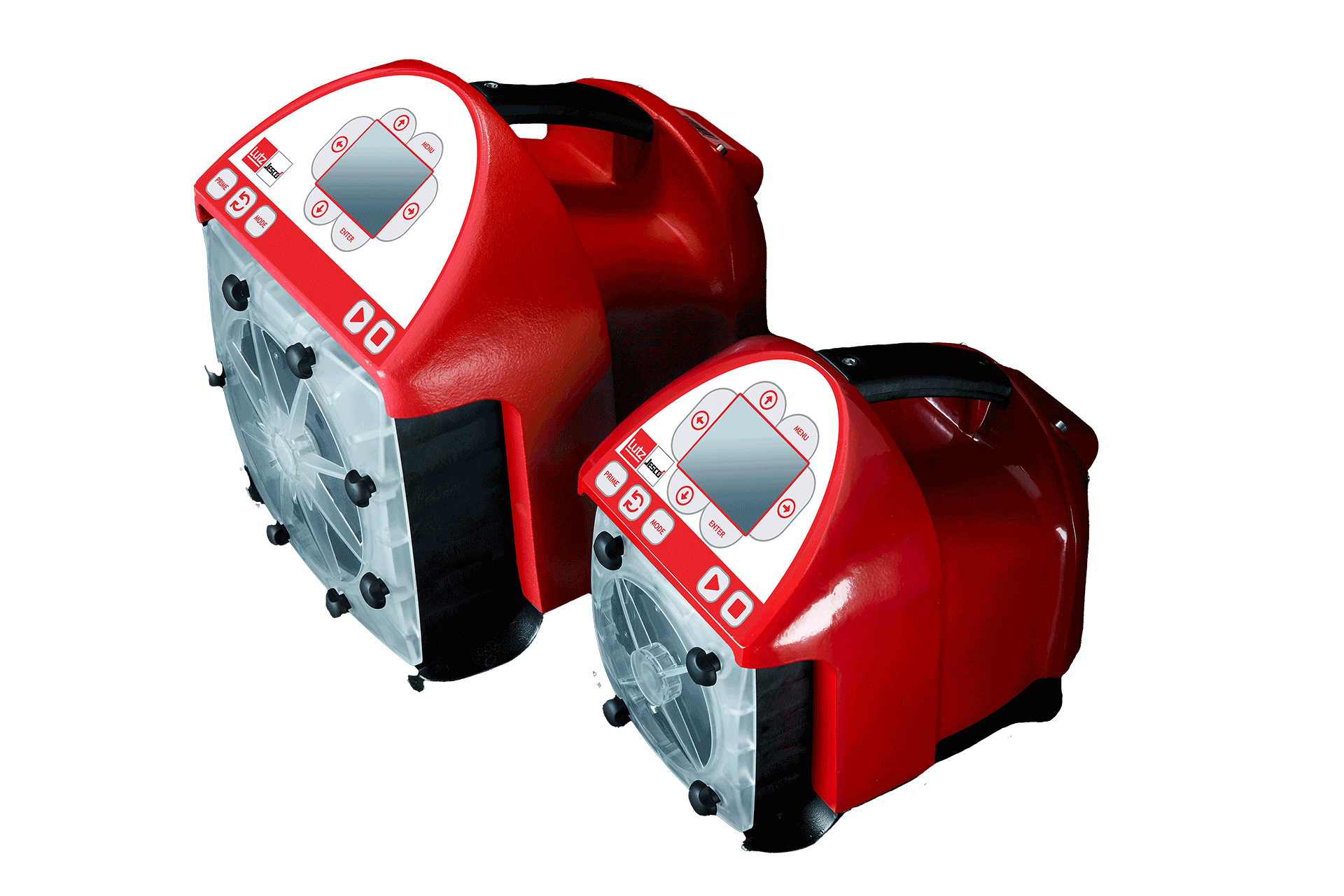

Three performance classes – our peristaltic pump series at a glance

The peristaltic pumps of the PERIDOS FXM series are available with three output levels:

PERIDOS FXM 1 provides a delivered volume of 0.74 gal/h at a delivery pressure of 21.8 psi

PERIDOS FXM 2 achieves a maximum delivered volume of 46.5 gal/h at a delivery pressure of 125 psi

PERIDOS FXM 3 provides a maximum delivered volume of 221.9 gal/h at a delivery pressure of 65 psi

Different hose materials for minimal wear

Various hose materials are available to minimize wear. The hoses of the PERIDOS FXM are available in:

- Norprene (chemicals)

- Tygothane (oils and fats)

- Tygon coated Norprene (acids)

The hoses can be changed in just a few steps – without dismantling the pump or requiring special tools. This reduces downtime and maintenance costs.

Networked for Industry 4.0

The PERIDOS FXM peristaltic pump is designed for the requirements of Industry 4.0 applications. They can be easily integrated into SCADA and control systems.

- The pumps transmit operating data, such as temperature and motor status, to central control systems using standard protocols, including Ethernet/IP and Modbus TCP. This allows maintenance staff to intervene before an unplanned shut down occurs.

- An integrated capacitive leakage detection system (TLD) issues an early alarm if a hose is damaged.

- Models 2 & 3 can be combined with a Flow Verification Sensor (FVS) to monitor flow rates and immediately detect deviations – for reliable dosing processes and the highest product quality.

Our complete range of peristaltic pumps

infoljac@lutzjescoamerica.com