Delivery time on request

Product number:

0204-060

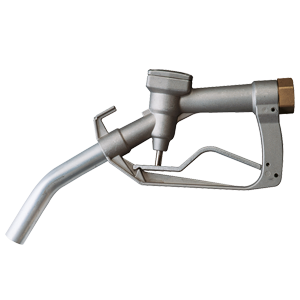

Product information "Dispensing nozzle Niro"

Description:

For dispensing and transferring liquids in the Foodstuffs and Pharmaceutical Industry as well as flammable and highly flammable liquids. The housing and the valve plug of the dispensing nozzle are made of stainless steel (1.4571) and are equipped with a protective bracket and a swivel coupling.

- EPDM seal is available on request at an extra charge

- Connection: external thread G 1 1/4"

Properties & advantages

- For pumping in potentially explosive environments

- Simple adjustment of the volume flow

- Easy to operate

- Safe filling or transferring of the respective liquid

- Rotary coupling ensures tightness at high pressure

| Accessory Group: | Nozzles |

|---|---|

| Certification: | ATEX Directive (ATEX Directive 2014/34/EU) |

| Explosion protection: | Yes |

| Flow rate (up to max. g/min)*.: | 13.21 |

| Housing (Material): | Stainless Steel |

| Liquid temperature (max. °C): | 80 (176,0 °F) |

| Operating pressure (max. bar): | 3 |

| Product group: | Drum pumps / Container pumps |

| Static seal (Material): | FEP / FPM, FPM (fluororubber) |

| Thread (inch) outside: | 1 1/4" |

| Type: | Dispensing nozzle Niro |

| Viscosity (up to max. mPas)*.: | 760 |