Delivery time on request

Product number:

5000-140

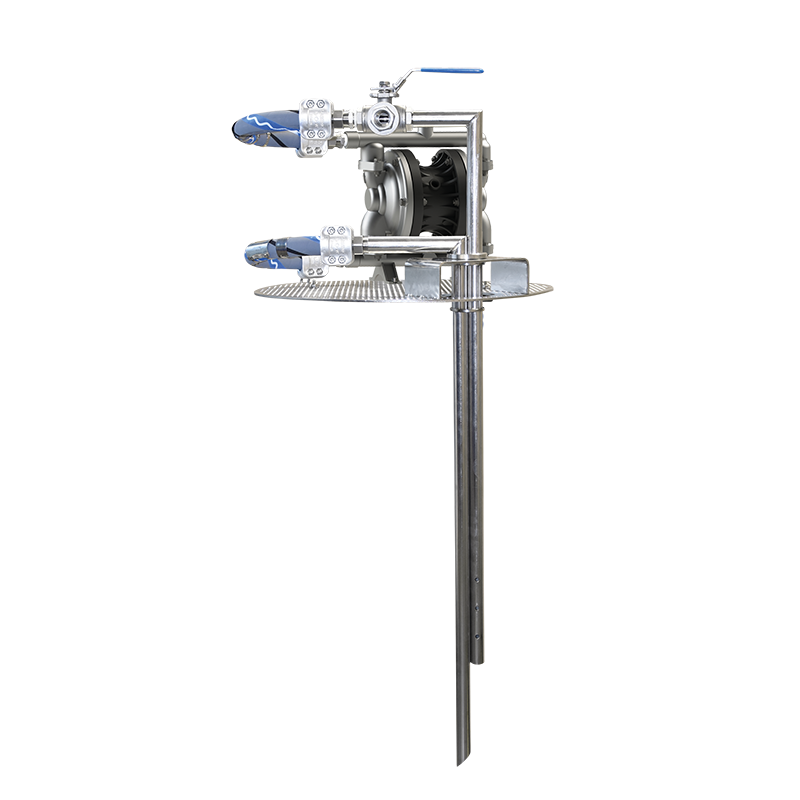

Product information "Diaphragm pumps mixing system"

Description:

For liquids that need to be mixed before processing and then pumped or that also contain small solids, the new Diaphragm pump mixing system with an integrated compressed air-driven double Diaphragm pump is the perfect solution. The mixing and pumping process takes place via a suction and mixing pipe and a 3-way valve. The pre-assembled system is ready for immediate use in just a few simple steps and is also suitable for potentially explosive liquids.

- Mixing and pumping integrated in one system

- Examples of media: Paints and varnishes, emulsions, dispersions, suspensions, water/oil mixtures, liquids with increased Viscosity and solids content

Properties & advantages

- Quick installation and time savings thanks to simple handling

- Compact design

- Base plate offers good stability on the container lid

- Easy to insert into the 2" bunghole of the container using a balancer or overhead crane

- No additional mixer required

| Certification: | ATEX Directive (ATEX Directive 2014/34/EU) |

|---|---|

| Check ball (Material): | PTFE (polytetrafluoroethylene) |

| Check valve seat (Material): | Stainless steel |

| Design/Equipment: | Bolted version |

| Diaphragms (Material): | PTFE (polytetrafluoroethylene) |

| Flow rate (up to max. g/min)*.: | 15.06 |

| Housing (Material): | Stainless Steel |

| Liquid temperature (max. °C): | 93 (199,4 °F) |

| Operating pressure (max. bar): | 8,2 |

| Seals (Material): | EPDM (ethylene propylene diene rubber), FPM (fluororubber), NBR (acrylonitrile butadiene rubber), PTFE (polytetrafluoroethylene) |

| Size (Inches): | 1/2" |

| Solids (max. ø mm): | 3,2 |

| Suction lift dry (in feet): | 4,3 |

| Type: | DMP 1/2" SST SS/PTFE |