„We have been a partner to the global food and beverage industry for almost 70 years. The state-of-the-art technology of our products and system solutions not only enables our partners to improve product quality and food safety and optimize their production process but also helps them to reduce operating costs and strengthen sustainability“ - Heinz Lutz, CEO of Lutz-Jesco GmbH

A long service life and minimal downtime

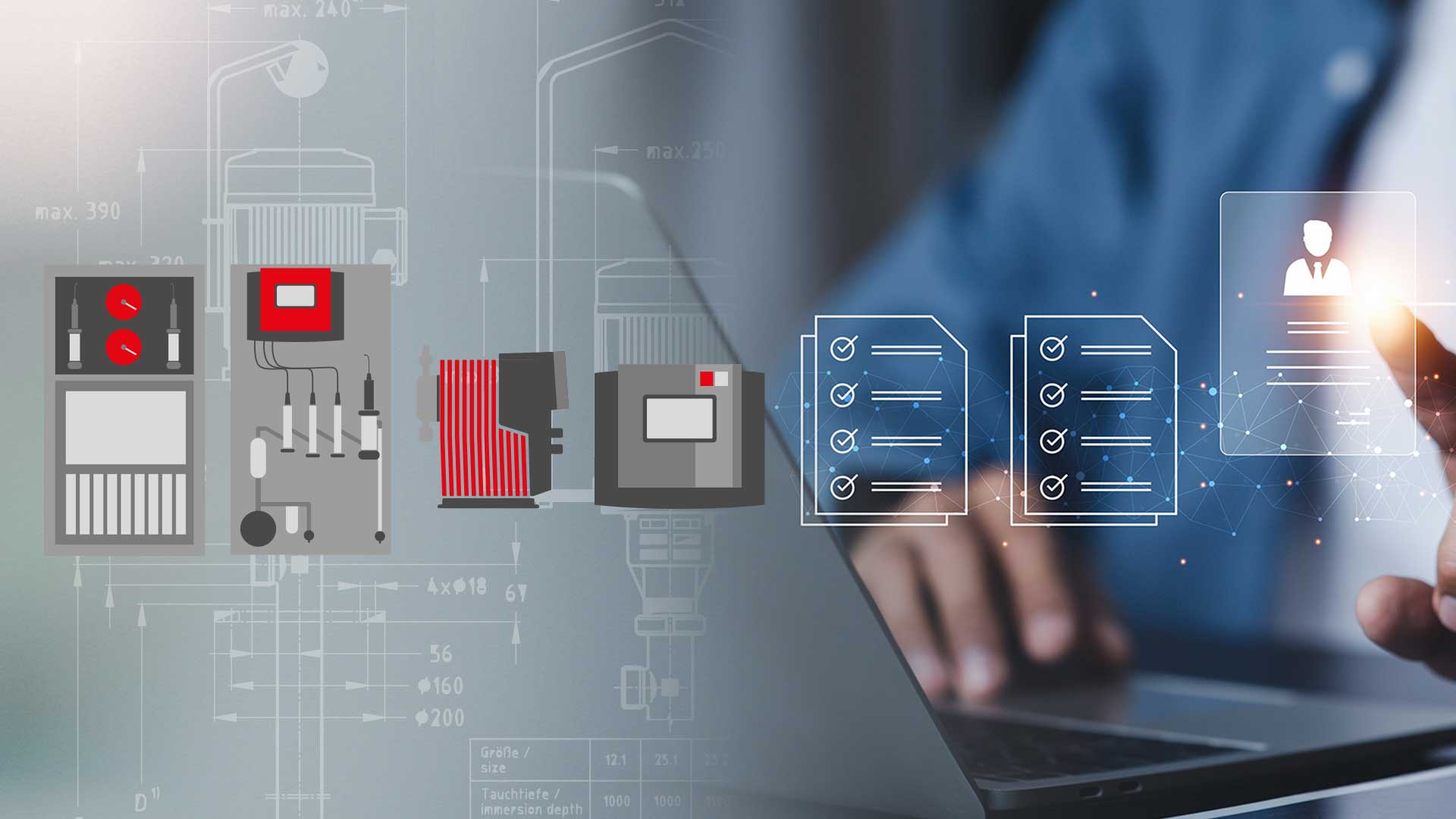

Lutz-Jesco dosing stations and disinfection systems are designed to meet the requirements of the food and beverage industry. Our systems ensure precise dosing of ingredients, aromas and additives in order to ensure a consistent product quality. They also guarantee reliable water treatment, which is crucial for compliance with strict hygiene standards. The robust design of our systems means that they offer a long service life and minimise downtime, which increases operational efficiency and reduces total operating costs. Lutz-Jesco thus complies with the requirements for top product quality, cost-effectiveness and sustainability, which are crucial in the food and beverage industry.

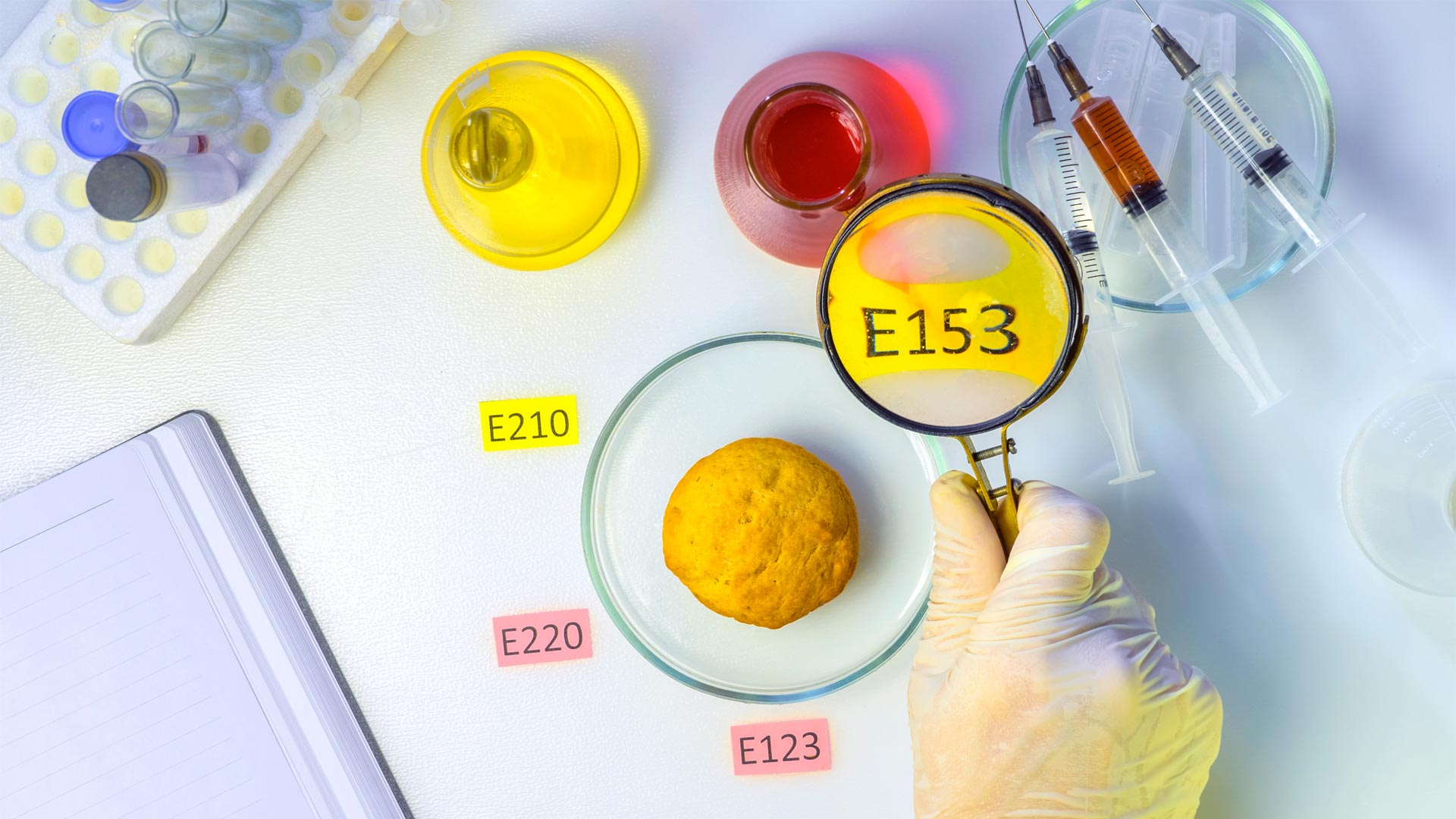

When hygiene is priority number one

Lutz-Jesco products set standards in terms of hygiene and safety. A hygienic design that enables easy cleaning and disinfection and the use of FDA-compliant materials ensures maximum food safety. As an active member of the European Hygienic Engineering & Design Group (EHEDG), Lutz-Jesco always keeps up to date with the latest hygiene directives. ISO 9001:2015 certification for quality management and ISO 14001:2015 certification for environmental management underscore our commitment to the highest standards of quality and hygiene.

Please contact us. We can work together to find the right solution!

Lutz-Jesco solutions provide companies in the food and beverage industry with maximum flexibility. The provision of over 150 products available in thousands of versions enables us to adapt the capacity and functionality of our product range to meet user needs – from the affordable solenoid diaphragm dosing pump to our complete, Industry 4.0-compatible dosing station including control and accessories. Contact us today to find out more about our products. Together we can design a customised solution to meet your needs.

Applications for the food and beverage industry

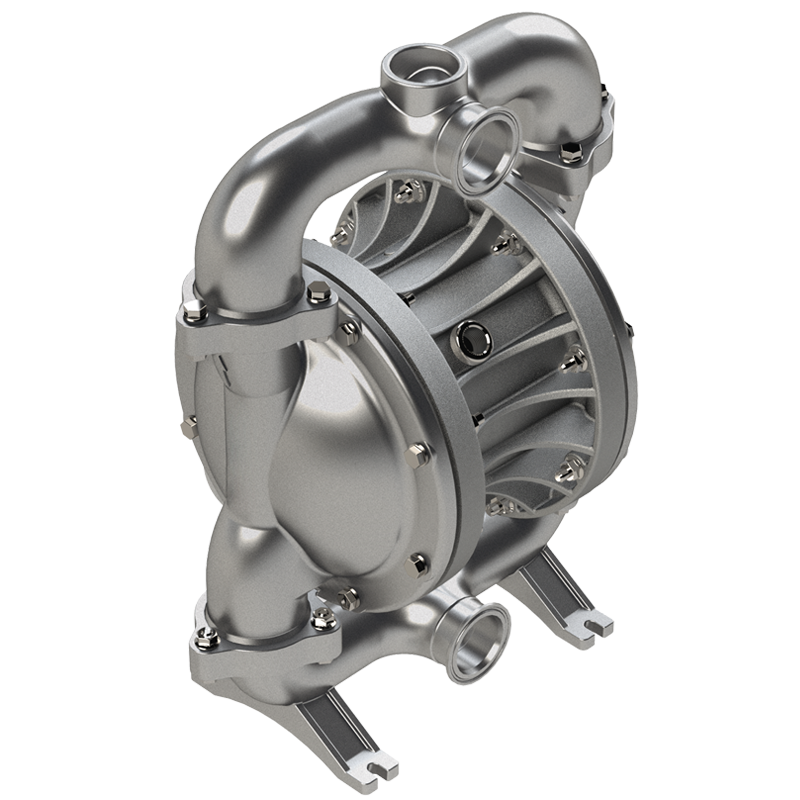

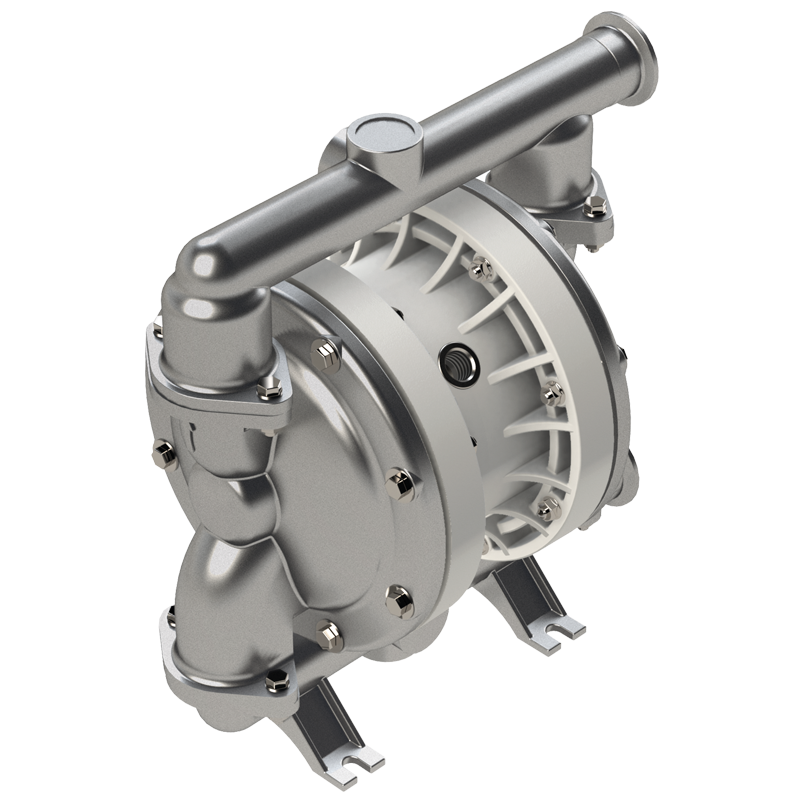

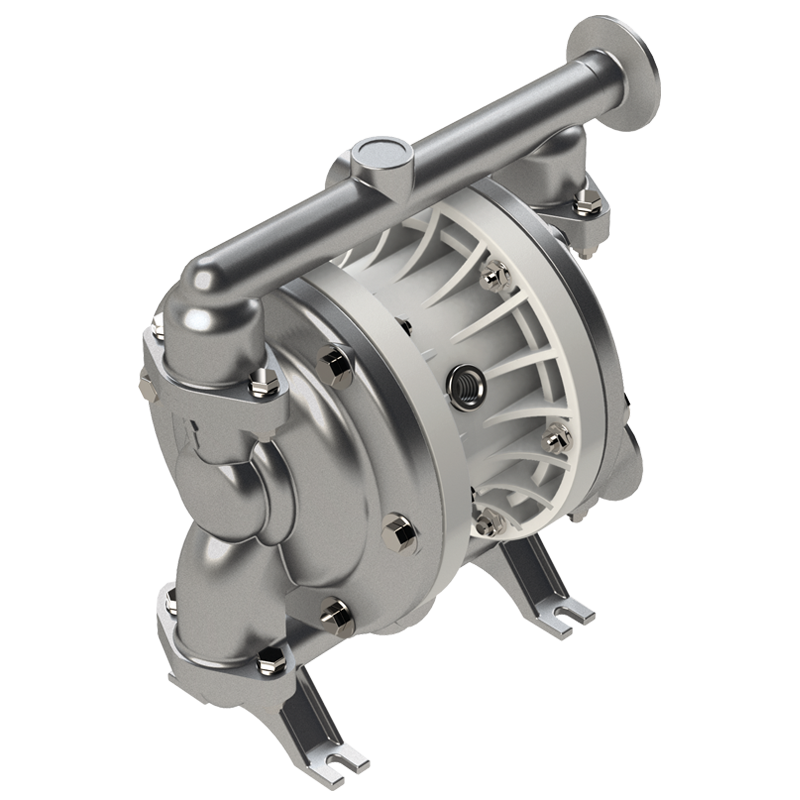

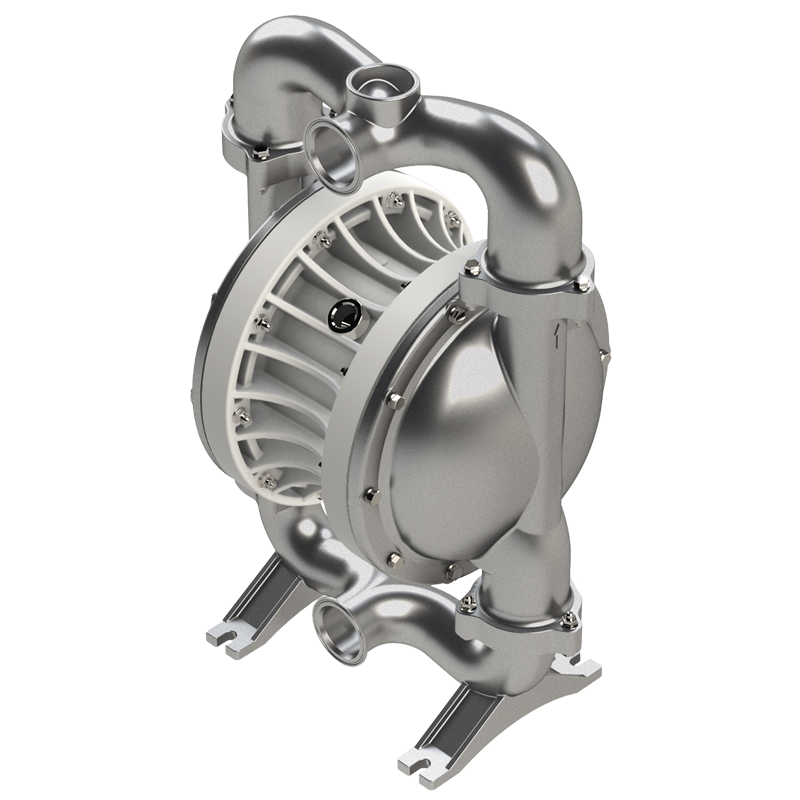

Products for the food & beverage industry

info@lutzpumpsamerica.com