Preventing Regrowth

Microorganisms can potentially re-enter the water after primary disinfection, either through breaches in the distribution system or during maintenance. Secondary disinfection combats this by maintaining a residual disinfectant, like chlorine, that continuously inactivates or kills any new microorganisms.

Protecting Water Quality

By maintaining a disinfectant residual, secondary disinfection helps ensure that the water remains safe and of high quality as it travels through the distribution system to the end consumer.

Addressing Vulnerable Populations

In situations where people may be more susceptible to waterborne illnesses, like hospitals or care homes, secondary disinfection is especially important.

Common Secondary Disinfectants

Chlorine

A widely used disinfectant, chlorine is often used in its free form or as monochloramine, a combination of chlorine and ammonia.

Chlorine Dioxide

A powerful oxidizing disinfectant that can be effective against a wide range of microorganisms.

Copper/Silver Ions

These ions can be released into the water to inhibit microbial growth, particularly effective against Legionella.

Ultraviolet Radiation (UV)

UV disinfection can be used as a secondary disinfection method, often alongside chlorine, to enhance the overall disinfection process.

Primary disinfection:

is the initial disinfection process that aims to kill or inactivate pathogens at the source, like a water treatment plant.

Secondary disinfection:

comes after primary disinfection and focuses on maintaining a residual disinfectant throughout the distribution system.

Importance in Different Settings

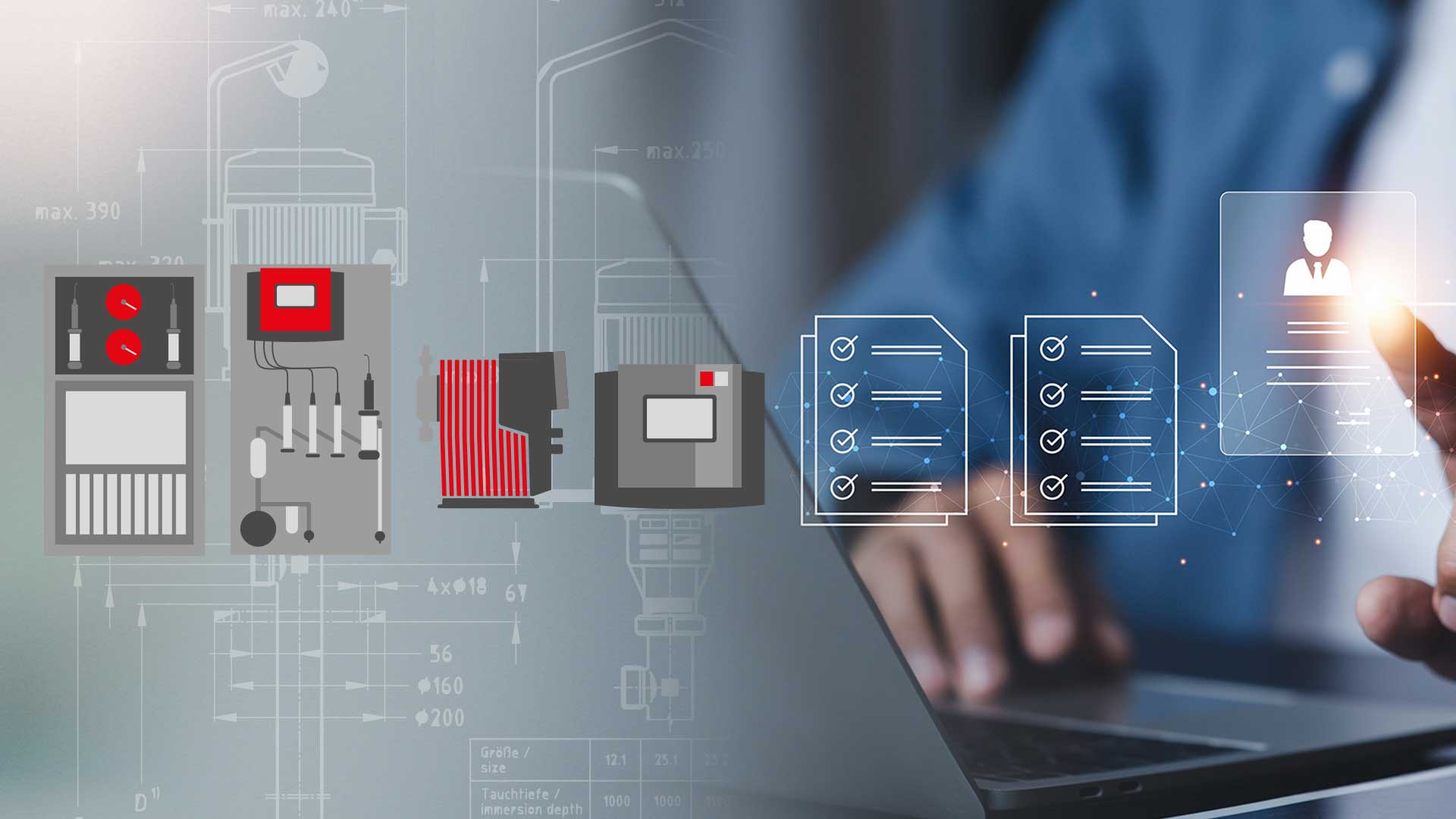

Products for the disinfection industry

info@lutzpumpsamerica.com