Our complete range of standard systems

horizontal

Pump set B200 PVDF

for concentrated acids and alkalis

Description:

The horizontal pump set is suitable for emptying highly aggressive, aqueous to slightly viscous media from IBC containers or tanks and is the perfect alternative to vertical Drum pumps. Perfectly suited for the removal of concentrated acids and alkalis.

Optionally with leakage detection (safety box)

Horizontal connection at the bottom of the container

Properties & advantages

Optionally with electric or compressed air drive

Low loss of medium when disconnected

Simple installation

Easy to dismantle

Small space requirement

Automatic emergency stop function of the motor when leakage is detected

Battery

Trolley B1 & B2 Battery

Mobile filling station

Description:

The B1 & B2 Battery Trolley is the ideal companion when it comes to mobile chemical refuelling. The safe transport ensures that even small quantities are no longer spilt. They are equipped with our latest battery pumps and are available with or without flow meters. The B1 & B2 Battery drum pumps stand for long battery life, low weight and low noise levels. The integrated aeration system enables the liquids to be extracted continuously. Large wheels facilitate handling over stairs and off-road. The hose holder and the hook on the Lutz nozzle prevent the hose from slipping and provide optimum protection.

External dimensions in cm: 100 x 59 x 43

Capacity up to 100 litres

Suitable for cleaning agents and chemicals

Technical data for the TR3 flow meter can be found directly with the respective product

Properties & advantages

max. volume flow 20 l/min

Viscosity up to max. 400 mPas)*.

All-terrain wheels with pneumatic tyres (Ø 300 mm)

Can be completely closed with a lid

Secure holder for Pump tube and Pump during transport

Polyethylene tank with integrated handle

stationary

Gas pendulum system

for stationary operation

Description:

Harmful gases and vapours remain practically in a closed system when filling or transferring hazardous liquids and ensure the necessary pressure equalisation themselves. Operationally safe connection thanks to a fixed screw connection on the Tank. A Ball valve: and a quick-release coupling ensure quick and safe drum changes.

Consisting of: Stopcock, connection fittings, sealing cap, double-sided closing, non-drip quick-release coupling, hose connection with union nut

Properties & advantages

Prevents the escape of harmful gases

Protects against oxidising emissions

For stationary operation

Backflow of trapped gases when the pump stops is stopped by a non-return valve

Hydraulic drum emptying system

with follower plate

Description:

The mobile, hydraulic drum emptying system with follower plate from Lutz is specially designed for the gentle emptying of drums filled with highly viscous, paste-like and viscous substances thanks to its infinitely variable operation. The food pump is suitable for highly viscous Foodstuffs and cosmetic products

Tank/drum can be customised on request

Infinitely variable control of the follower plate via control valve

Examples of media: Lipstick, emulsion paint, ice cream, yoghurt, tomato paste, etc.

Properties & advantages

Almost residue-free emptying of the drums

Pulsation-free conveying/emptying

Easy cleaning by removing the Pump or the pump tube

Adjustable emptying speed

No lateral ejection of the medium due to unpressurised follower plate

Drums are secured by holding arms

horizontal

25 l/min.

Eccentric screw pumps B70H Industry

with transport trolley

Description:

The B70H is a modification of our B70V and is designed for horizontal use on a transport trolley. It can be used in situations where the B70V reaches its spatial or handling limits and thus rounds off our range of Eccentric screw pumps with a mobile variant. The pump is suitable for pumping aqueous to highly viscous Newtonian and non-Newtonian media as well as media containing solids and shear-sensitive media. It is also used in Explosion proof zones for aggressive and highly flammable liquids with high delivery pressure.

Explosion proof version also available on request

Horizontal version

With stainless steel transport trolley

Properties & advantages

Conveying possible at low room heights

No physical strain due to heavy lifting

Mobility is provided by the transport trolley

Simple resizing possible

Easy handling of pumps with large weights

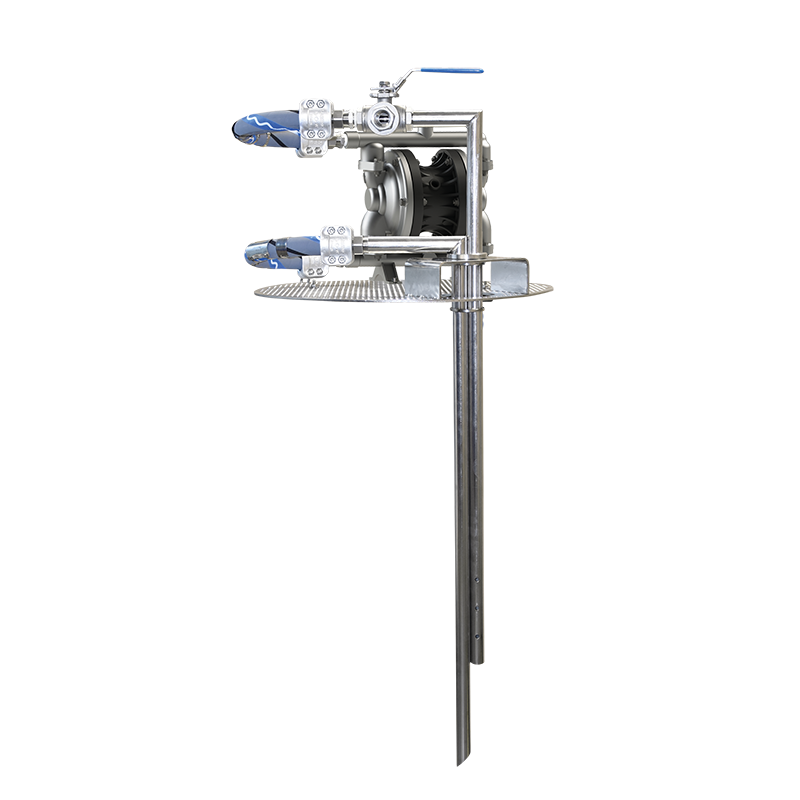

Diaphragm pumps mixing system

Mixing and pumping (explosion-proof)

Description:

For liquids that need to be mixed before processing and then pumped or that also contain small solids, the new Diaphragm pump mixing system with an integrated compressed air-driven double Diaphragm pump is the perfect solution. The mixing and pumping process takes place via a suction and mixing pipe and a 3-way valve. The pre-assembled system is ready for immediate use in just a few simple steps and is also suitable for potentially explosive liquids.

Mixing and pumping integrated in one system

Examples of media: Paints and varnishes, emulsions, dispersions, suspensions, water/oil mixtures, liquids with increased Viscosity and solids content

Properties & advantages

Quick installation and time savings thanks to simple handling

Compact design

Base plate offers good stability on the container lid

Easy to insert into the 2" bunghole of the container using a balancer or overhead crane

No additional mixer required

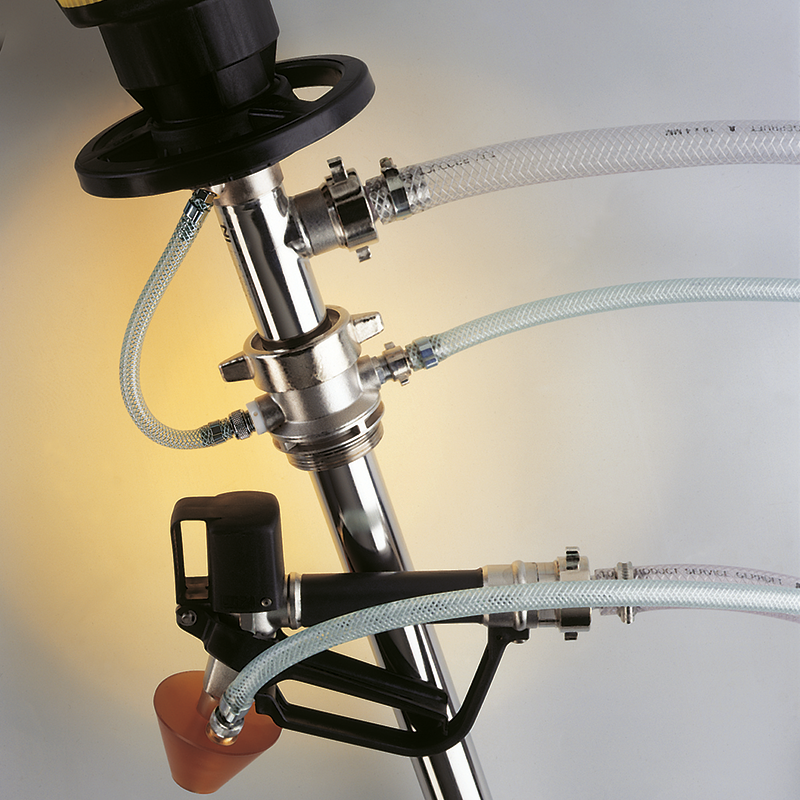

Gas pendulum system

for handling strongly oxidising or fuming acids and alkalis

Description:

Harmful gases and vapours remain practically in a closed system when filling or transferring hazardous liquids and ensure the necessary pressure equalisation themselves. The sealing plug adapts to different drum and container openings (D = 40-75 mm). Enables safe decanting, even into smaller containers, in conjunction with a dispensing nozzle. A non-return valve integrated into the vapour return line prevents the gases from flowing back when the Pump stops or the drum is changed.

Consisting of: Conical sealing plug, non-return valve for vapour return line, screw-in fittings

Properties & advantages

Prevents harmful gases from escaping

Protects against oxidising emissions

Backflow of trapped gases when the pump stops is stopped by the non-return valve

mobile

Gas pendulum system

for mobile operation with fuming acids and alkalis

Description:

Harmful gases and vapours remain practically in a closed system when filling or transferring hazardous liquids and ensure the necessary pressure equalisation themselves. The sealing plug adapts to different drum and container openings (D = 40-75 mm). Enables safe decanting, even into smaller containers, in conjunction with a dispensing nozzle. A non-return valve integrated into the vapour return line prevents the gases from flowing back when the Pump stops or the drum is changed.

Consisting of: Conical sealing plug, non-return valve for vapour return line, screw-in nipple with union nut and hose nozzle and hose clamps

Properties & advantages

Prevents harmful gases from escaping

Protects against oxidising emissions

For mobile operation

the backflow of trapped gases when the pump stops is stopped by the non-return valve

Your contact person

Lutz-JESCO America Corp.

Do you have questions about dosing pumps, disinfection systems, chlorine dosing systems, system and process technology or measurement and control technology?

Our team of experts will be happy to assist you. Please send us an enquiry or call us directly.

+1 5854260990

infoljac@lutzjescoamerica.com