CHEMICAL FEED SYSTEMS FROM LUTZ JESCO

FOR MUNICIPAL, INDUSTRIAL, AND OEM APPLICATIONS

APPLICATIONS

Lutz-JESCO’s Chemical Feed Systems are successfully used in a wide range of industrial and municipal markets, including:

- Greenhouse

- Pulp & Paper

- Petrochemical

- Cooling Towers

- Pharmaceutical

- Food & Beverage

- Water & Wastewater Treatment

- OEM

- Boilers

- Chemical

- Car Wash

- Power & Energy

- Swimming Pools

- Drinking Water Treatment

FEATURES

By working closely with the project engineer, Lutz-JESCO provides its extensive experience in the field of metering technology to offer you Chemical Feed Systems in a variety of options:

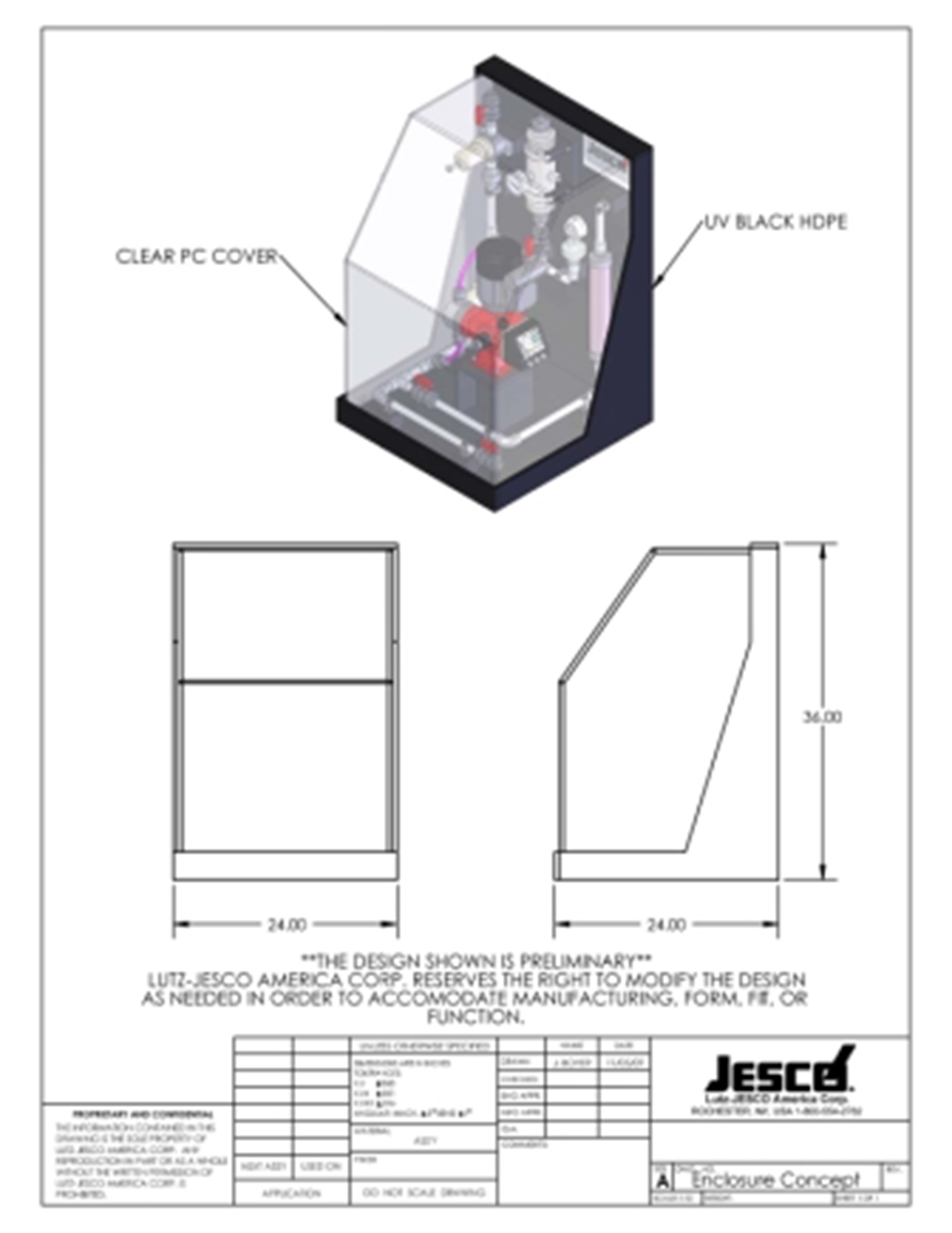

- CFS weldment materials: black or colored UV protected HDPE, 316SS, PP, EPOXY coated steel, FRP

- Plumbing materials: 316SS, PVC, PP, PVDF

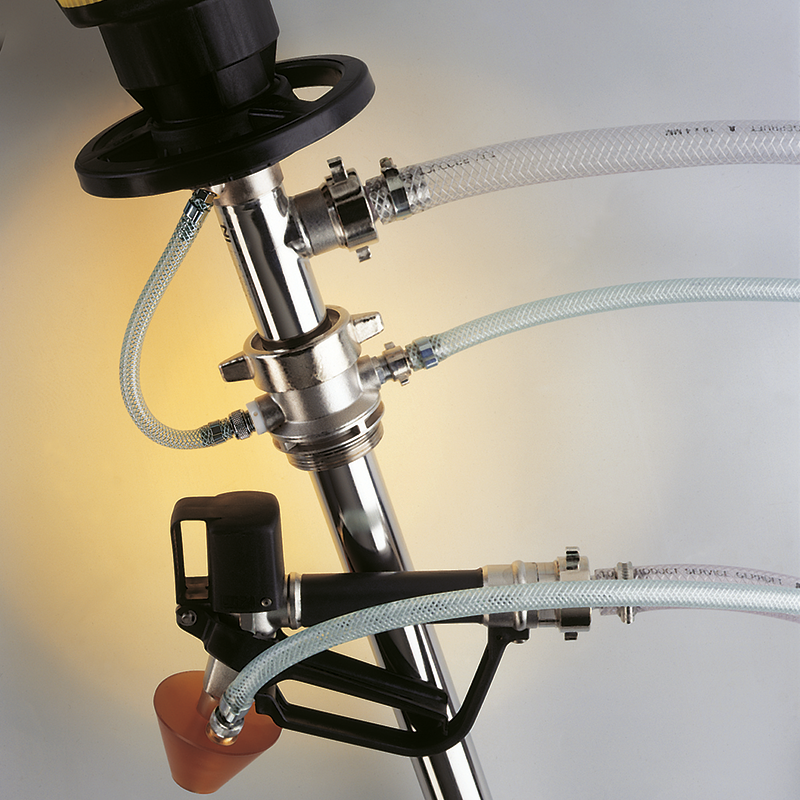

- Systems may include: Any combination of single or multiple metering or transfer pumps, Tanks and Mixers, Measuring and Control Equipment, any combination of pump accessories

CHEMICAL SERVICES

The broad range of materials available for Lutz JESCO skids allows for a wide selection of chemicals to be processed, including:

- Aluminum Sulfate

- Phosphoric Acid

- Aqua Ammonia

- Potassium Permanganate

- Calcium Hypochlorite

- Powder Activated Carbon

- Ferric Chloride

- Sodium Bisulfite

- Fluoride

- Sodium Hydroxide

- Hydrochloric Acid

- Sodium Hypochlorite

- Hydrogen Peroxide

- Sulfuric Acid

- phosphates

Find out about our categories of system and process technology

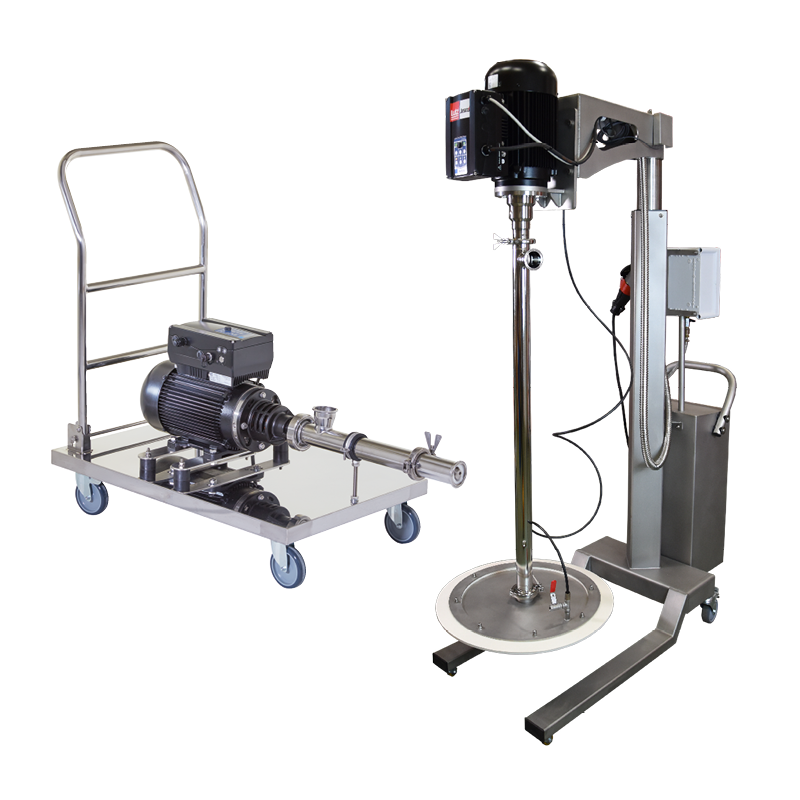

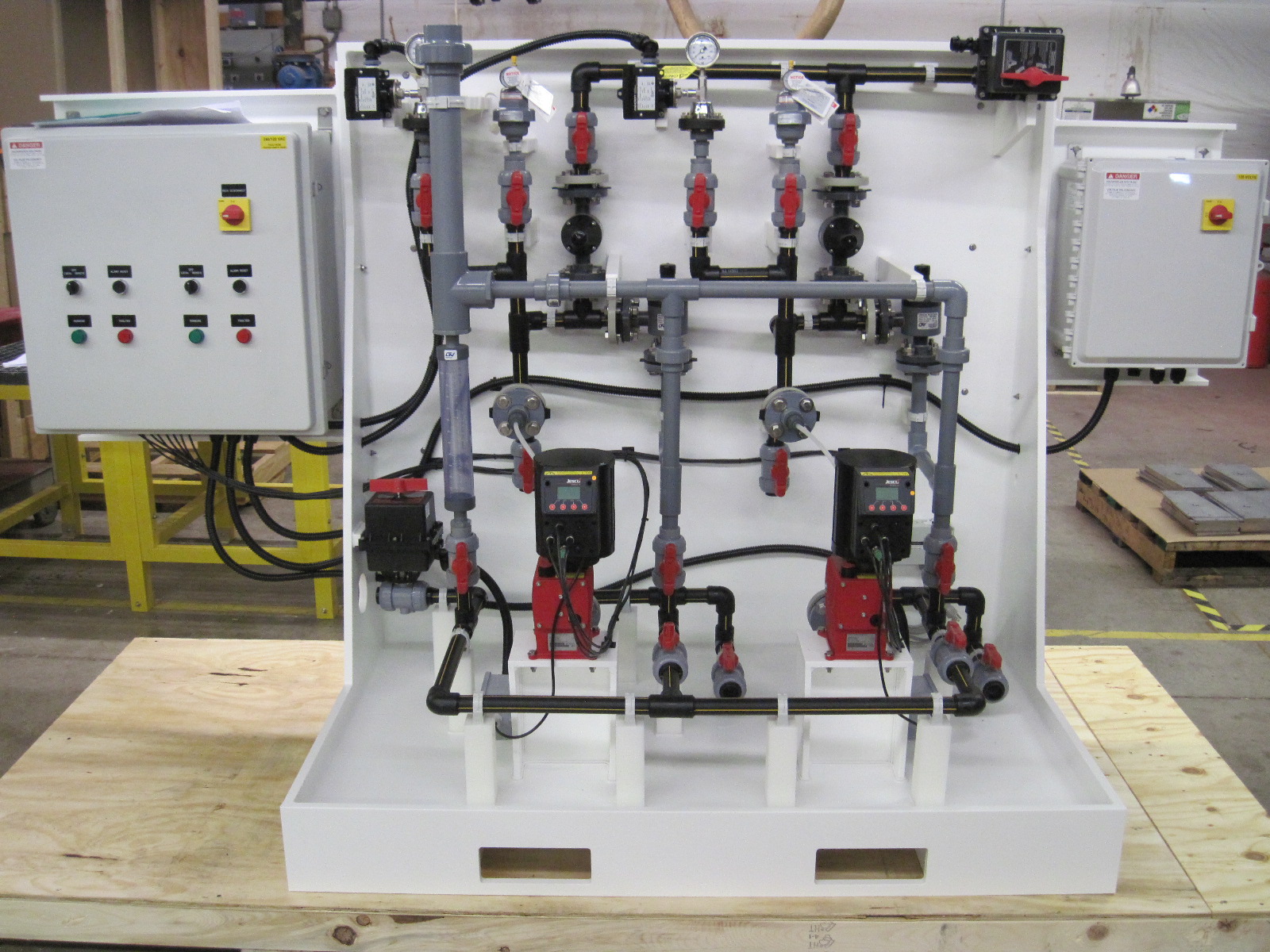

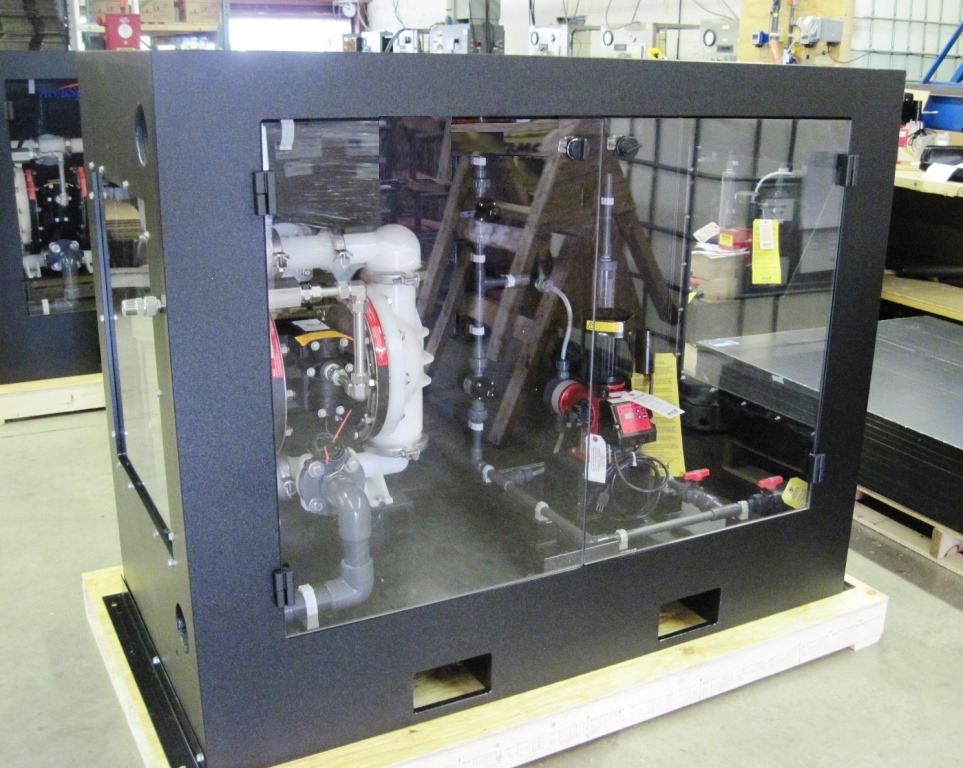

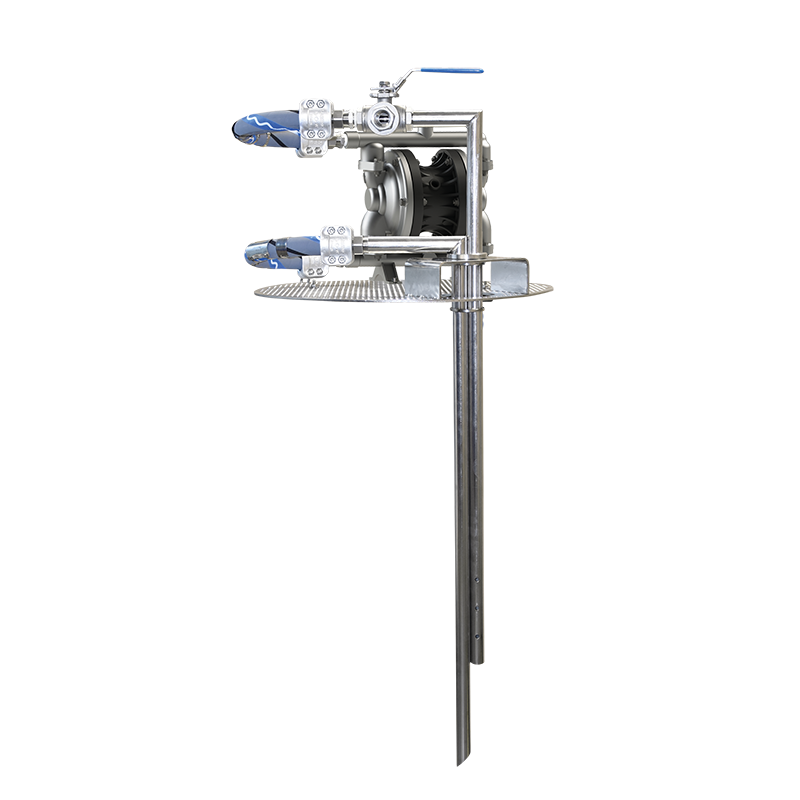

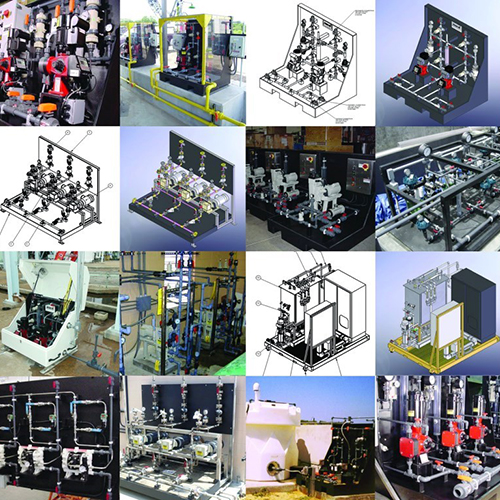

SKID-, WALL-, TANK MOUNTED

-

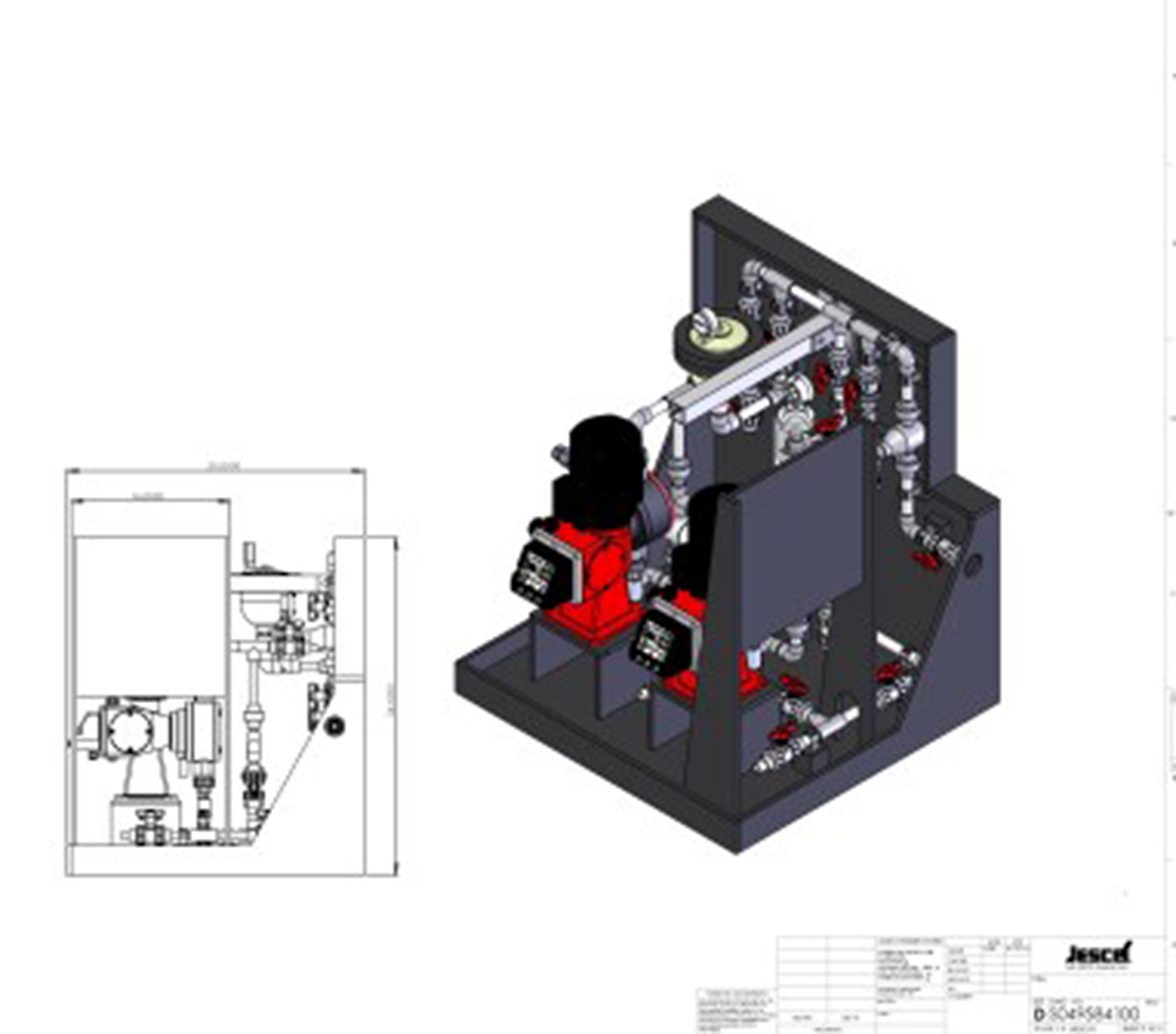

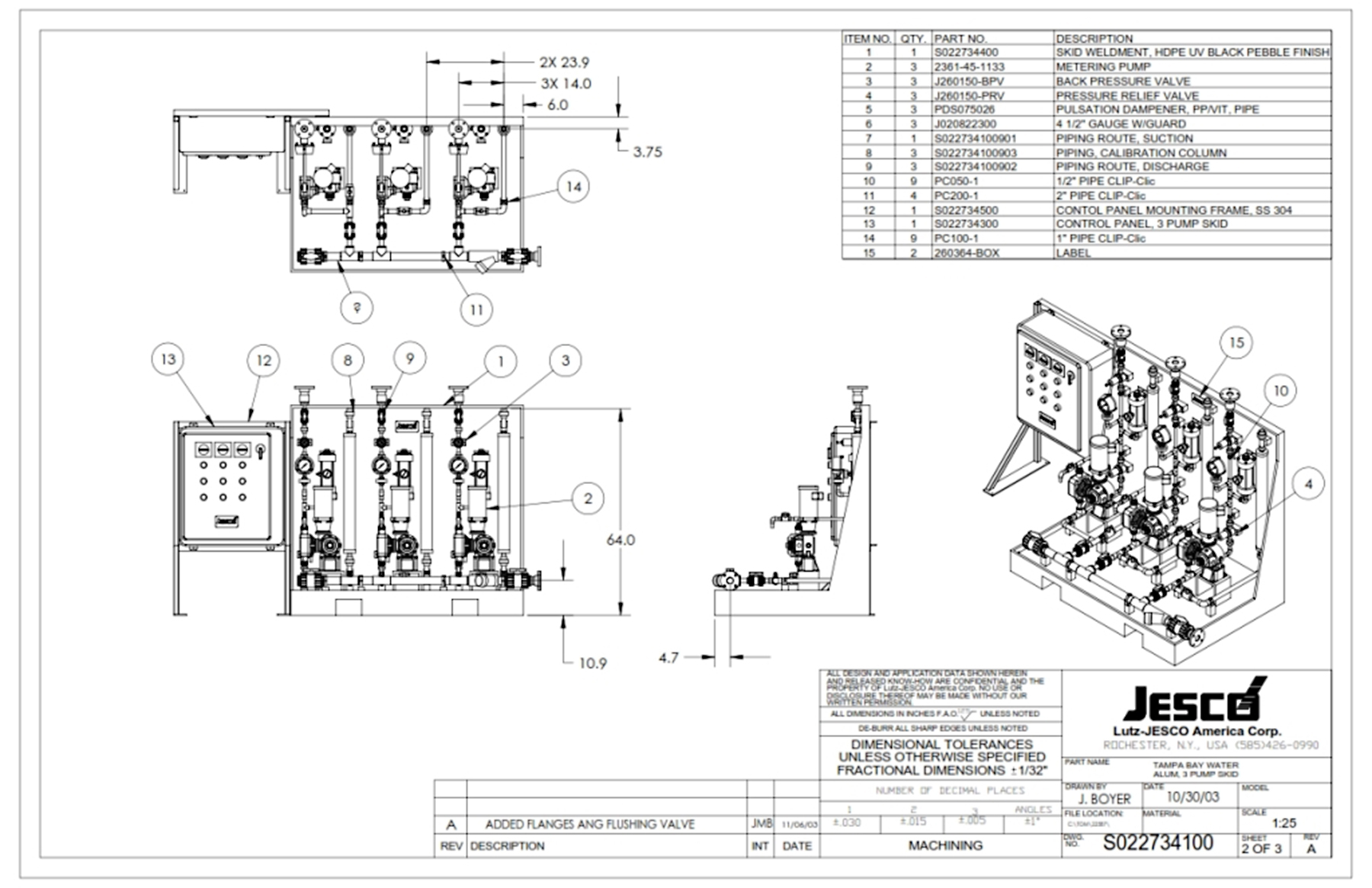

Lutz - Jesco Skid Mounted Systems can accommodate larger pumps, making them ideal for larger flow applications. Skid Mounted Systems also offer containment, controlling chemicals in case of leakage.

-

Our Wall Mounted Systems feature a very space efficient design. Their small footprint makes them ideal for limited space as they are mounted directly above the chemical storage tanks. Their design also makes them easily accessible for maintenance.

- Tank Mounted Systems give the customer chemical storage, metering, and mixing in one convenient package. Their portable design makes them not only ideal for temporary installations, but allows also for easy relocation as application needs may change.

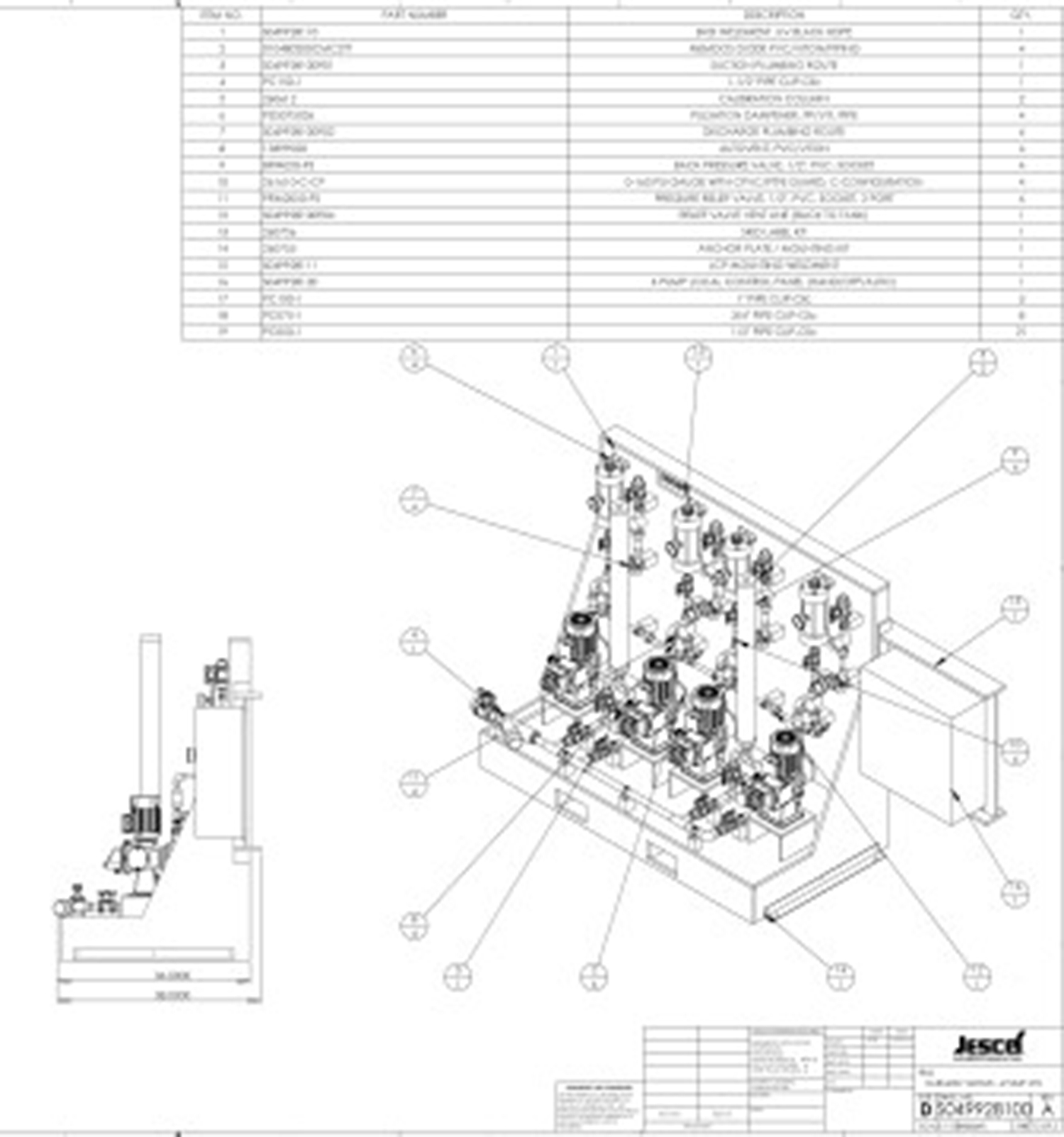

CUSTOM DESIGNED SYSTEMS

Lutz-JESCO also designs, within extremely competitive delivery terms, Chemical Feed Systems built precisely to the customer’s specific application needs.

All of our custom systems are fully tested and calibrated and include all supporting documentation.

Custom designed Chemical Feed Systems can include:

- Single or multiple Metering or Transfer Pumps

- Accessories

- Tanks

- Mixers

- Control Panels

LUTZ - JESCO CHEMICAL FEED SYSTEMS

-

IN-HOUSE ENGINEERING, DESIGN AND PRODUCTION

Backed by our extensive knowledge and experience in Chemical Feed System design and manufacture, you get one integrated solution for your specific chemical feed requirements.

-

REDUCE COST, INCREASE RELIABILITY

Buying a complete Chemical Feed System from Lutz-JESCO America offers many advantages. Reduce cost, facilitate start-up and maintenance, increase ststem reliability and maintain single-source system responsibility.

-

"TURN-KEY" OR CUSTOM-DESIGNED AND BUILT

Choose our standard, pre-engineered systems for common applications or talk to us about a custom-engineered system to meet your precise needs.

OUR SERVICES

LUTZ - JESCO SYSTEMS Complete Engineering, Design, and Production

Lutz-JESCO America manufactures the highest quality Chemical Feed Systems in the market. We Engineer, Design, and Manufacture all Chemical Feed Systems In-house, providing System Integration while maintaining single-Source Systems Responsibility. Lutz JESCO Systems reduce your Costs, eliminate Construction Delays, reduce Start-up Constraints, and streamline Documentation.

ONE INTEGRATED SOLUTION FOR YOUR SPECIFIC

CHEMICAL FEED REQUIREMENTS

IN - HOUSE ENGINEERING

Lutz-JESCO’s Chemical Feed Systems are designed and engineered completely in-house, so we take responsibility for the entire system.

Our in-house engineering services include:

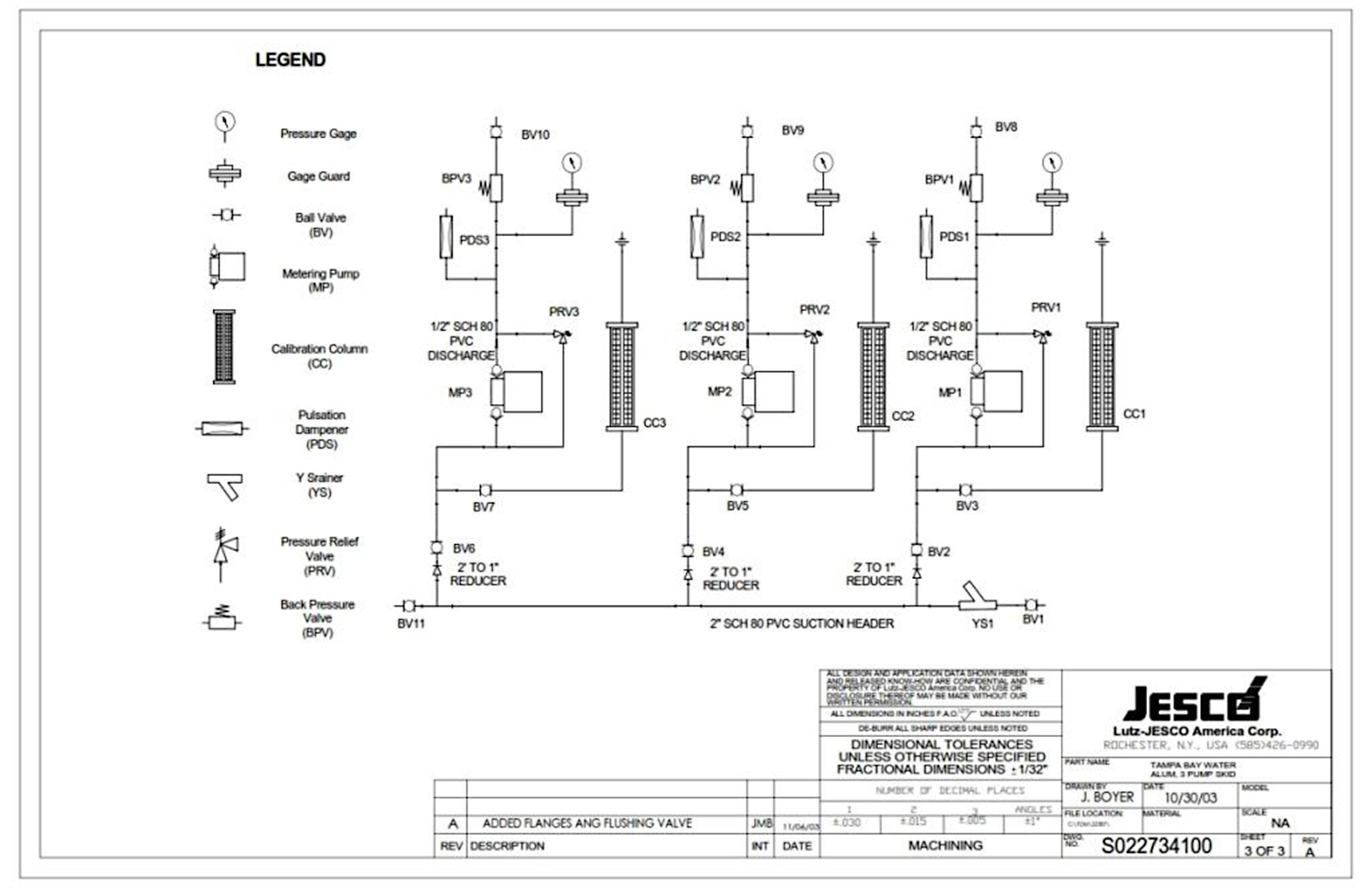

- 3D CAD / Solidworks Mechanical engineering and modeling Design

- Skid structural Design, Piping Design, Routing Design

- P&ID drawings and Installation Drawings

- Electrical and Mechanical Engineering in-house

IN - HOUSE PRODUCTION

Using only precision tools and equipment, Lutz-JESCO manufactures the highest quality Chemical Feed Systems in the market.

Our in-house production capabilities include:

-

Plastic Fabrication

- Cutting and Welding (HD)PE, (C)PVC, standards are 1 ½” and 2” thickness

- For Tank-, Wall-, Floor- mounted Pumping Systems

- Welded by DVS certified welder, according to SKZ / DVS 2212 certifications - Welding of (316) SS piping

- PVDF (Kynar) Fusion Welding

- FRP (Fiber-Reinforced Plastic) fabricated Skids

- Control Panel Integration / System- Wiring and Connection

POST - SALES SERVICES

To maintain and extend the quality of your Chemical Feed System, Lutz-JESCO offers a broad range of post sales services and technical assistance, including:

- Start-up Service

- Demand / On-call Service

- Maintenance Service on-site

- Technical support, both off- and on-site

- Submittals / Documentation preparation

ADVANTAGES OF LUTZ JESCO CHEMICAL FEED SYSTEMS

PRECISION FABRICATION, SINGLE SOURCE RESPONSIBILITY

- Reduced Cost, Streamlined Documentation, Eliminated Construction Delays, Reduced Start Up Constraints

- Provide system Integration while maintaining single-Source Systems Responsibility

- Each System is designed with Practical and Reliable Operation in Mind

- System is Hydrostatically Tested for Flow, Pressure and Performance at Factory

- Simplified Field Integration for Easy Installation and Start-up - only three field connections are required: Suction, Discharge, and Power

- Ease of Access to all Components (ball valves, calibration columns, relief valves, controls, etc.)

REDUCED COSTS, INCREASED EFFICIENCIES

- Spill Containment Basin with Drain for preventive Maintenance

- Factory Assembled, using only Precision Tools and Equipment

- Comprehensive Warranty

- Design, Layout, and Engineering Assistance

- Established Written Specifications and Drawings for Ease of Equipment Selection and Incorporation into Master Plans

- Each System is Serialized for Identification of all Components

- Chemical Resistance Guaranteed on all Components

Our complete range of system and process technology

info@chemicalfeedsystems.com