Mobile pumps make the industry more flexible

Wertheim, December 3, 2024 - Mobile pump solutions are becoming increasingly important in the industry because they offer maximum flexibility and rapid operational readiness - especially in changing or unpredictable working environments. Lutz Pumpen will therefore be exhibiting at the Pump & Valves 2025 trade fair in Dortmund from 19 to 20 December. The B70H progressing cavity pump, which can be moved flexibly on a transport trolley, and the battery-powered B3 Battery drum pump will be on show at the trade fair on February 2025 (Hall 005, Stand 5-L09).

The progressive cavity pumps of the B70 series are used in industry for pumping aqueous to highly viscous liquids with up to 100,000 mPas as well as solids-containing and shear-sensitive media - from diesel and oil in the raw materials industry, to caramel and pasta in the food industry, to toothpaste and cream in the cosmetics industry.

"The pumps of the B70 series are known for their gentle and low-pulsation pumping, so that the structure and properties of sensitive food products, pharmaceuticals, biochemicals and polymers remain unchanged during transportation," explains Takumi Nasu, Head of Development at Lutz-Pumpen GmbH. The pumps work with an eccentric screw that rotates in a static housing, dividing the medium into individual chambers and transporting it along these chambers. This gentle conveyance results in only a low mechanical load on the medium, which minimizes the risk of shear stress.

Uniform flow rate without pressure peaks and dead times

The progressive cavity pumps in the B70 series also operate with low pulsation. "The flow rate is even and takes place without strong pressure peaks. This is not only beneficial for the stability of the pumped medium, but also minimizes the dead time during which no liquid is pumped," says Nasu. With a three-phase motor and up to 900 revolutions per minute, the pumps achieve a flow rate of up to 120 l/min, a delivery head of up to 6 bar and are suitable for immersion depths between 500 mm and 2,500 mm. Indirect flow measurement via the speed of the rotor is also possible. "As some users also value mobility in order to be able to use the pump in multiple locations, we have launched the B70H version for horizontal use on a transport trolley that can be easily pushed by one person. This solution is also suitable for space-constrained conditions - for example in areas with low ceiling heights."

Empty a 200-liter drum 14 times on one battery charge: B3 takes on wired variants

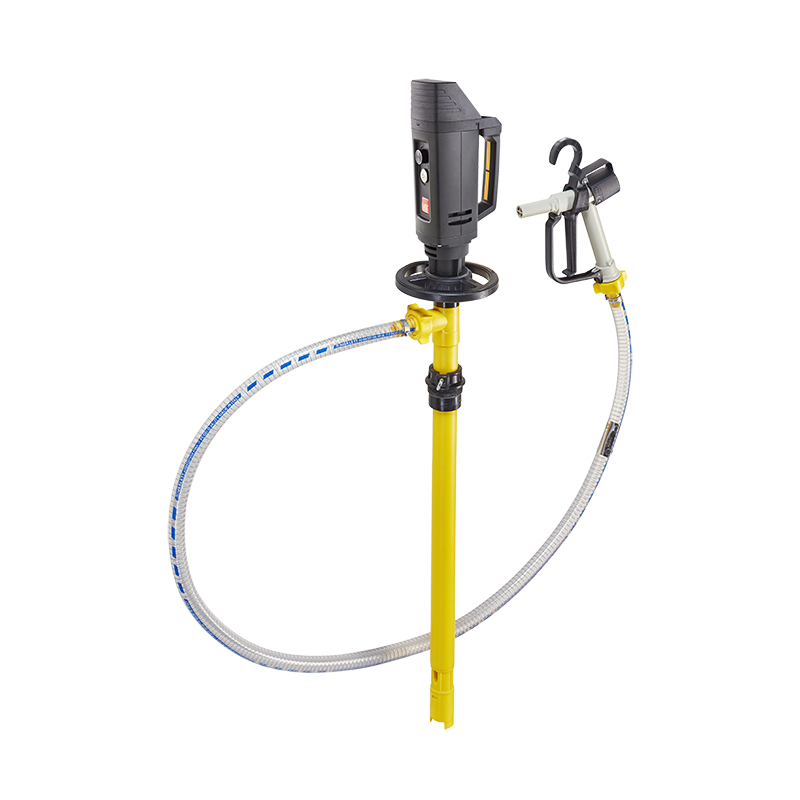

At Pump & Valves 2025, Lutz Pumpen will be presenting another mobile pump solution: the B3 Battery, a battery-powered drum pump that is suitable for mobile emptying of liquids from drums, canisters and IBC containers. The new pump is used in the chemical industry for transferring acids, alkalis or solvents, in the food and beverage industry for pumping liquids such as syrups, essences or cleaning agents, in water treatment and in agriculture for pumping fertilizers or pesticides.

"With the B3 Battery, we have succeeded for the first time in making the performance of a battery-operated drum pump comparable to that of cable-connected versions," says Andreas Rössler, Head of Sales at Lutz Pumpen GmbH. The pump works with a brushless 320-watt DC motor, which offers a delivery rate of up to 180 liters per minute and a delivery head of 11.8 meters of water column. One battery charge is enough to empty a 200-liter drum 14 times in just under 15 minutes. At a lower speed, for example, an IBC container with 1,000 liters can be pumped out 5.8 times in 51 minutes. The pumping station is available in different versions to pump as many chemicals as possible for water treatment, including a version made of polypropylene (PP) for sodium hydroxide and polyvinylidene fluoride (PVDF) for chloric acid.

About Lutz Holding GmbH

Lutz Holding GmbH has stood for professional fluid management since 1954. The group of companies unites internationally active companies in pump technology as well as water treatment and disinfection and is represented by 13 subsidiaries and agencies in over 80 countries worldwide. The group includes Lutz Pumpen GmbH in Wertheim, Lutz-Jesco GmbH in Wedemark and Lutz-Jesco Suisse SA in Couvet, Switzerland. The portfolio includes pumps, systems and accessories for dosing, conveying, emptying and mixing processes for a wide range of media. Lutz Group products are used in numerous sectors, including the chemical industry, food industry, automotive production, water and wastewater treatment as well as the paint and coatings industry.