The challenge: precise dosing of phosphate in water treatment

A common method of water treatment is the addition of phosphate to prevent corrosion and limescale deposits. However, precise dosing of the phosphate is crucial for protecting the boiler.

The operator of a co-generation plant in Salzburg recognised the vital importance of finding a dosing pump that automatically adds the right amount of phosphate. After all, the reliability of this solution is crucial for the stability of the district heating supply in the city.

The solution: the use of a Rekos KR 20 series dosing pump ensures reliable enrichment of the feed water with phosphate

With Lutz-Jesco, the operator of the Salzburg co-generation plant finally found what it had been looking for, an expert for water treatment with decades of experience in developing precise and durable dosing technology for industrial applications.

Rekos KR 20 series dosing pumps are now deployed in the co-generation plant in Salzburg. Piston pumps are specially designed to perform the repeated dosing of liquids with a high degree of accuracy and under high pressure. In co-generation applications, the pumps ensure that precise phosphate dosing keeps the chemical concentration of the feed water stable. This ensures that the system operates safely and efficiently.

Dosing pumps achieve operating times of up to 40 years

A decisive advantage of the Rekos KR 20 pumps lies in their robustness and resistance to chemicals. As a result, they can achieve an operating time of up to 40 years without the need for frequent maintenance or replacement.

What's more, the dosing pumps are able to pump the phosphate into the feed water even under very high pressure of up to 200 bar – a necessity, as the water in the co-generation plant itself is under high pressure.

The pumps also permit flexible integration into the power plant's control systems. This allows operators to work efficiently to adapt and monitor operations in order to continually optimise the performance and safety of the district heating supply.

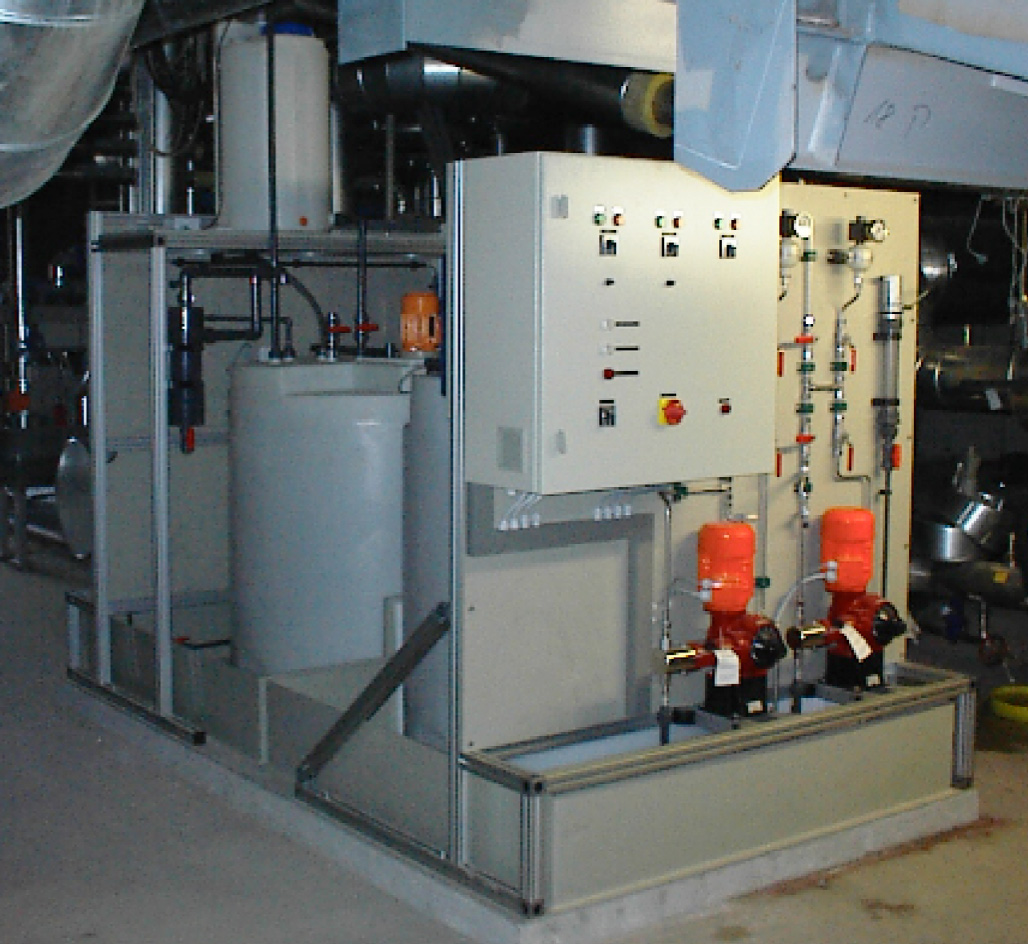

More than just a dosing pump: Lutz-Jesco supplies a turnkey system

As the operator of the co-generation plant needed to be able to commission the new solution as quickly as possible, Lutz-Jesco supplied a turnkey system.

In addition to its dosing pumps, the system consists of the following components: a 1000-litre tank for storing the one-percent phosphate solution; an agitator to ensure even mixing and homogeneity of the solution in the tank; a pulsation damper to minimise pressure fluctuations in the line and thus ensure even dosing; a pressure-relief valve to protect the system against positive pressure; a collecting pan for the safe collection of any leaking liquids; and a control cabinet to control and monitor the entire dosing system.

All components are fitted ready for operation. This significantly reduces the on-site installation time and permits quick commissioning. The turnkey solution also reduces the risk of faults and malfunctions, as the system is comprehensively tested by Lutz-Jesco prior to delivery.

The co-generation plant in Salzburg deploys the Rekos KR 20 series dosing pumps to optimise the reconditioning of the feed water. This not only extends the service life of the systems, but also helps to ensure a continuous district heating supply for the city.

Customer benefits

Precise and reliable dosing:

the Rekos KR 20 dosing pumps ensure the precise addition of phosphate, protecting the boiler and heat exchanger against corrosion and preventing deposits.

Durability and high resistance:

with an operating time of up to 40 years and a pressure resistance of up to 200 bar, the pumps are robust and low-maintenance.

Complete turnkey solution:

Lutz-Jesco supplies a pre-installed system with all the necessary components, which enables rapid commissioning and minimises installation times.

info@lutz-jesco.ch