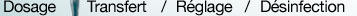

MEMDOS KMS

-

Ease of installation

- Quick diaphragm change possible

- No zero-point correction with dismantling of the piston flange required

- The rational structure requires only a minimum of spare parts storage

- The addition of a second dosing unit to the drive with an identical or different capacity range produces a double head pump, the MEMDOS ZKMS.

- Thanks to its symmetrical form, the piston flange can be installed on the left-hand or right-hand side of the simple pump.

This ensures an economical and compact system design. - Due to the installation of only four stud bolts, the dosing pump can be converted from manual stroke adjustment to electrical stroke adjustment.

- For operation, motors with a multi-range voltage

(220 – 240/380 – 420 V, 50 Hz; 440 – 480 V 60 Hz), a high protection class (IP55) and a high insulation class (F) are used.

Special motors (ATEX) on request. - TÜV-checked pressure relief valves are integrated in all pumps; these prevent damage to the pump and the periphery.

The pressure relief valves have been selected to match the pump capacity and the desired maximum pressure in the system.

High flexibility

Further product views

| MEMDOS KMS, KMS-HP | 6 | 9-HP | 12 | 24 | 24-HP | 46 | 80 | 100 | 140 | 137 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Delivery capacity at max. backpressure | 50 Hz | l/h | 6.3 | 9.2 | 12 | 24 | 46 | 80 | 100 | 140 | 137 | |

| 60 Hz | 7.5 | 10.6 | 14 | 28.8 | 55.2 | 96 | - | 168 | 164 | |||

| Delivery capacity at max. backpressure | ml/stroke | 1.8 | 1.7 | 3.3 | 6.4 | 11 | 12 | 19 | 20 | |||

| max. delivery pressure | bar | 10 | 25 | 10 | 25 | 10 | 8 | 10 | ||||

| Max. stroke frequencyz | 50 Hz | rpm | 60 | 90 | 120 | 140 | 120 | 112 | ||||

| 60 Hz | 72 | 108 | 144 | - | 144 | 134.4 | ||||||

| Suction lift for non-gassing media | mWS | 2 | ||||||||||

| Piston diameter | mm | 14 | 20 | 27 | 37 | 45 | 32 | |||||

| Nominal valve width | DN8 | DN20 | ||||||||||

| Weight | PVC | kg | 11 | - | 11 | - | 11 | 15 | 31 | |||

| PVDF | 11 | - | 11 | - | 11 | 15 | 31 | |||||

| Stainless steel (1.4571) | 12 | 13 | 12 | 18 | 40 | |||||||

| Approved ambient temperature | °C | -5 to +45 | ||||||||||

| Approved media temperature | °C | -5 to +45 | ||||||||||

| Dosing accuracy | % | 1 | ||||||||||

| MEMDOS KMS, KMS-HP | 272 | 350 | 490 | 582 | 582-HP | 882 | 1058 | 1280 | 1536 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Delivery capacity at max. backpressure | 50 Hz | l/h | 272 | 350 | 490 | 582 | 882 | 1058 | 1280 | 1536 | |||

| 60 Hz | 326 | 420 | 576 | 698 | 1058 | - | 1536 | - | |||||

| Delivery capacity at max. backpressure | ml/stroke | 41 | 52 | 73 | 87 | 131 | 126 | 190 | 183 | ||||

| max. delivery pressure | bar | 10 | 6 | 4 | 10 | 4 | |||||||

| Max. stroke frequency | 50 Hz | rpm | 112 | 140 | 112 | 140 | |||||||

| 60 Hz | 134.4 | - | 134.4 | - | |||||||||

| Suction lift for non-gassing media | mWS | 2 | |||||||||||

| Piston diameter | mm | 45 | 52 | 58 | 65 | 80 | 95 | ||||||

| Nominal valve width | DN20 | DN32 | |||||||||||

| Weight | PVC | kg | 33 | 40 | 42 | 60 | 85 | 90 | 100 | ||||

| PVDF | 33 | 40 | 42 | 60 | 85 | 90 | 100 | ||||||

| Stainless steel (1.4571) | 42 | 45 | 47 | 65 | 90 | 100 | 120 | ||||||

| Approved ambient temperature | °C | -5 to +45 | |||||||||||

| Approved media temperature | °C | -5 to +45 | |||||||||||

| Dosing accuracy | % | 1 | |||||||||||

Technical data for highly viscous media

| MEMDOS KMS-V | 12-V | 20-V | 50-V | 137-V | 175-V | 235-V | 291-V | 440-V | 640-V | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Delivery capacity at max. backpressure | 50 Hz | l/h | 12 | 20 | 50 | 137 | 175 | 235 | 291 | 440 | 640 | ||

| 60 Hz | 14 | 24 | 60 | - | 210 | 282 | 349 | 528 | 768 | ||||

| Delivery capacity at max. backpressure | ml/stroke | 6.7 | 11.1 | 18.5 | 40.8 | 52.1 | 69.9 | 86.6 | 131 | 190.5 | |||

| max. delivery pressure | bar | 10 | 6 | 10 | 4 | ||||||||

| Max. stroke frequency | 50 Hz | rpm | 30 | 45 | 56 | ||||||||

| 60 Hz | 36 | 54 | - | 67.2 | |||||||||

| Suction lift for non-gassing media | mWS | 2 | |||||||||||

| Piston diameter | mm | 27 | 37 | 45 | 52 | 58 | 65 | 80 | 95 | ||||

| Nominal valve width | DN20 | DN32 | |||||||||||

| Weight | PVC | kg | 13 | 15 | 68 | 74 | 80 | 100 | |||||

| Approved ambient temperature | °C | -5 to +45 | |||||||||||

| Approved media temperature | °C | -5 to +45 | |||||||||||

| Dosing accuracy | % | 1 | |||||||||||

Subject to technical changes

-

Operating manuals

MEMDOS KMS

MEMDOS KMS MEMDOS KMS

MEMDOS KMS MEMDOS KMS

MEMDOS KMS MEMDOS KMS

MEMDOS KMS

Product information

Deutsch

Deutsch English

English